114-13233

Rev B

12

of 13

NOTE

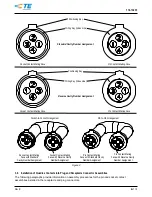

Connector shells must bottom for full engagement and seal compression.

3.20.

Repair/Replacement

CAUTION

Damaged components must not be used. If a damaged component is evident, it must be removed and replaced with a new

one. Terminated contacts and ferrules must not be re-terminated.

4.

QUALIFICATION

Quadrax DSub Connectors and Quadrax Contacts are not required to be agency evaluated and tested.

5.

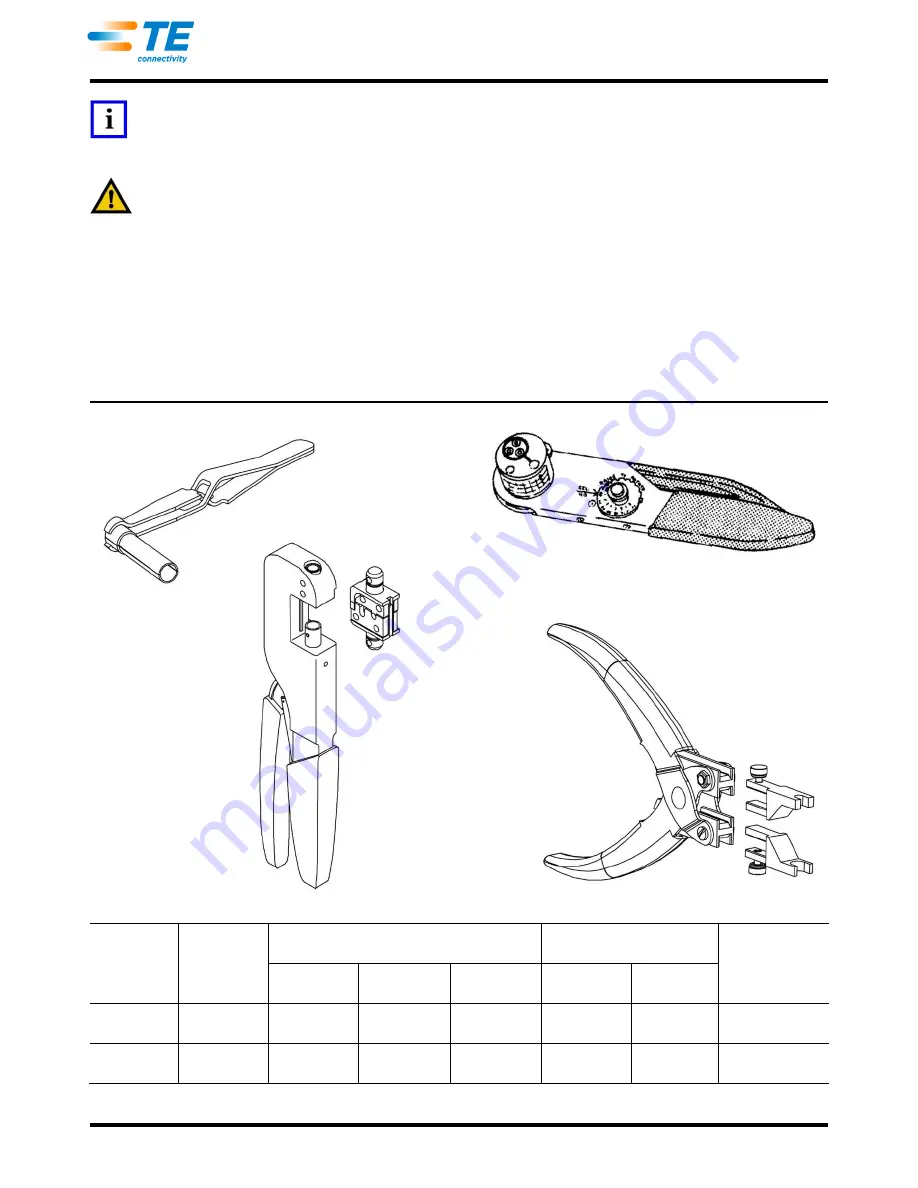

TOOLING

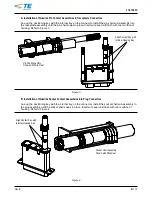

Quadrax Contacts and ferrules can be terminated using hand crimping tools that accommodate the wire size

specified. Military (DANIELS) tool, positioner, and die sets are available to crimp the screw-machine pin or

socket contact, and ferrule. See Figure 15 for recommended tooling.

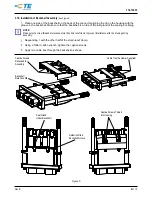

WIRE SIZE

(AWG)

CONTACT

TYPE

CONTACT TERMINATION TOOLING

FERRULE TERMINATION

TOOLING

RECOMMENDED

EXTRACTION

TOOL

HAND

TOOL

POSITIONER

OR DIE SET

SELECTOR

SETTING

HAND TOOL

DIE SET

26

Pin or Socket

M22520/2-01

K709

4

M22520/5-01

or 608650-1

5-45

1738894-1

24

Pin or Socket

M22520/2-01

K709

5

M22520/5-01

or 608650-1

5-45

1738894-1

Figure 15

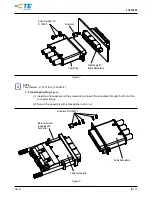

Recommended

Extraction Tool

1738894-1

Ferrule Termination

(Military) DANIELS

Tool and Die Set

Signal Contact Termination

(Military) DANIELS Tool

and Positioner

Ferrule Insertion Tool

1976593-1 (Socket 1445693)

and 1976593-2 (Pin 1445692)