114-13233

Rev B

3

of 13

Prolonged exposure to ultraviolet light may deteriorate the chemical composition used in the product

material.

B.

Shelf Life

The contacts and connector kits should remain in the shipping containers until ready for use to prevent

damage. These products should be used on a first in, first out basis to avoid storage contamination.

C.

Chemical Exposure

Do not store product near any chemical listed below as they may cause stress corrosion cracking in the

material.

Alkalies

Ammonia

Citrates

Phosphates Citrates

Sulfur Compounds

Amines

Carbonates

Nitrites

Sulfur Nitrites

Tartrates

NOTE

Where the above environmental conditions exist, phosphor-bronze contacts are recommended if available.

3.4.

Cable Selection and Preparation

Special considerations must be adhered to in the cable stripping operation.

A.

Selection

The pin and socket contacts will accept a wire size of 24 and 26 AWG in a 4-conductor (Quad) cable

configuration in 100 Ohm and 150 Ohm. Cable suppliers such as Raychem* and TENSOLITE may be

used. Contact TE to confirm all cable sizes and compatible contacts.

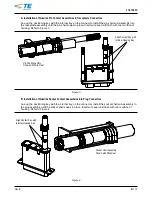

B.

Preparation

CAUTION

Reasonable care must be taken not to nick, scrape, or cut any conductors during the stripping operation.

NOTE

Dimensions and procedures for stripping the cable may be found on TE Application Specification 114-13123.

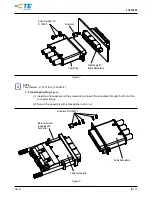

3.5.

Crimped Contact Requirements

NOTE

Dimensions and procedures for crimping the contacts may be found on TE Application Specification 114-13123.

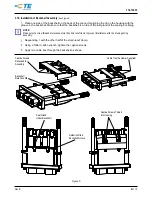

3.6.

Pin Contact Assembly

NOTE

Dimensions and procedures for assembling pin contacts and pin shell may be found on TE Application Specification

114-13123.

3.7.

Socket Contact Assembly

NOTE

Dimensions and procedures for assembling the socket contacts and socket shell may be found on TE Application Specification

114-13123.

3.8.

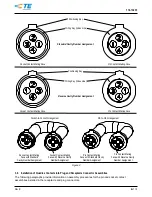

Contact Cavity Numbering

Figure 2 provides information on contact cavity numbering with regards to standard and reverse number

assignments for the pin and socket connector assembly per ARINC 600 Supplement 14.

NOTE

The same specific part number can be used as either a standard or reverse pin assignment. Cavity numbers 2 and 4 are the

same for either standard or reverse assignment. On standard wiring assignment, position 1 will be adjacent to the wiring key

(index line). On reverse assignment, position 3 will be adjacent to the wiring key. Standard verses reverse assignments are

dependent on the location of cavity numbers 1 and 3.

TENSOLITE is a trademark.