114-13233

Rev B

7

of 13

3.11.

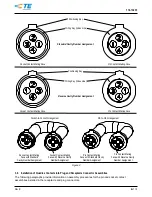

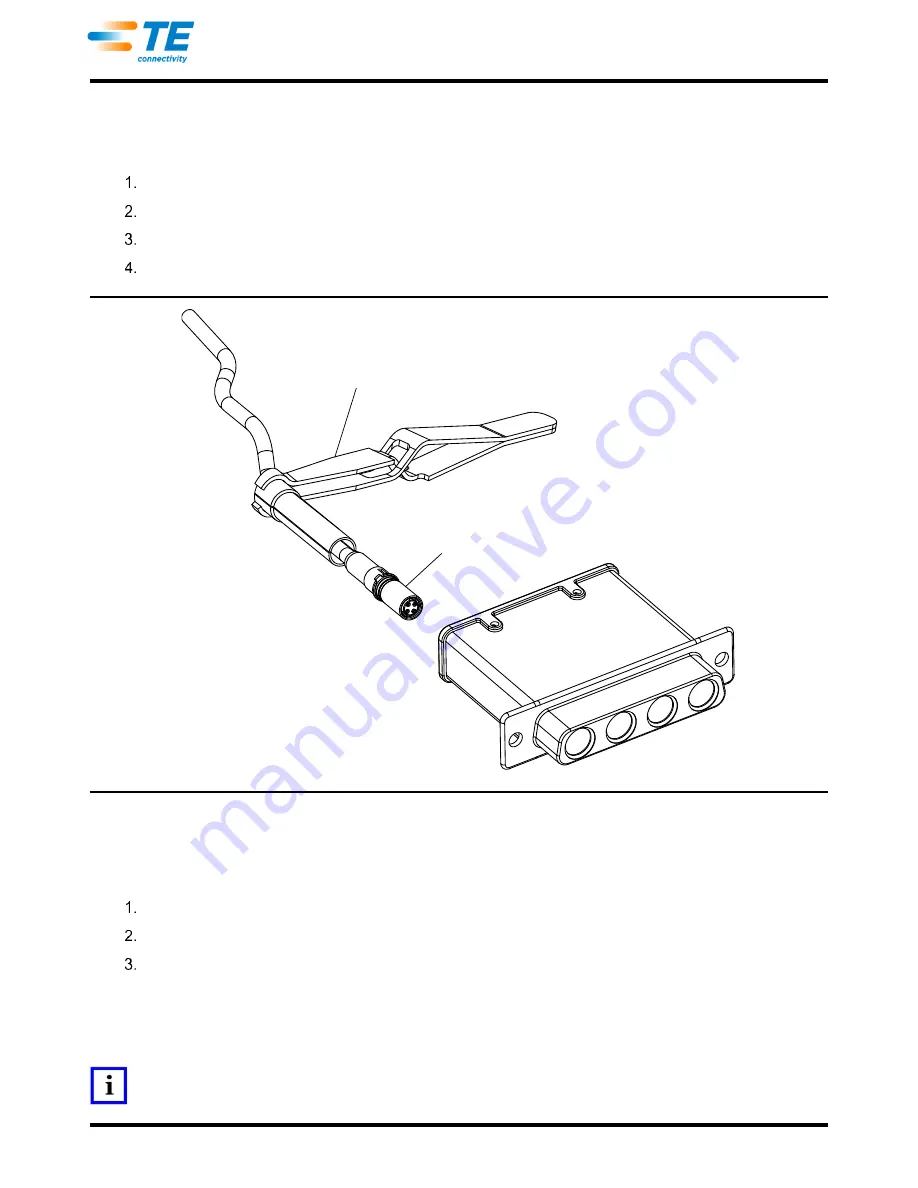

Removal of Quadrax Contacts from Plug and Receptacle Connector Assemblies (RR/RR)

Use recommended Extraction Tool 1738894-1 for removal of the pin or socket contacts from the plug or

receptacle connector assemblies. Refer to Figure 6.

Cut wire tie and remove backshell by loosening the captive screws.

Slide sealing boot back up the cable and out of the way.

Insert extraction tool over wire insulation and bottom the tool in the cavity hole.

Pull up while holding the tool and cable. Contact should easily come out.

Figure 6

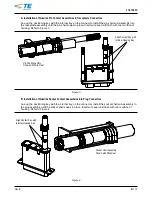

3.12.

Mounting Hardware

A.

Assembling Screw Retainer Kit (211883-5)

(Figure 7)

Align the oval (flat) side of the retainer with the front of the connector flange.

Slide the retainer onto the flange and align holes.

Thread the retainer screw through the retainer from the back of the flange.

B.

Assembling Screwlock Kits (212447-1)

a.

Right-Angle Receptacle

(Figure 7)

(1) Pass the screwlock through the panel and thread it into the threaded flange of the connector.

NOTE

Recommend torque for the screwlock assembly to be 0.45 N●m [4 in.-lb].

Socket Shell

NOTE:

Plug Connector Shown, Process

is Same for Receptacle Connector

Recommended Extraction

Tool 1738894-1