Raychem Devices

No: RCPS-200-20

Rev: E1

Date: August 10, 2016

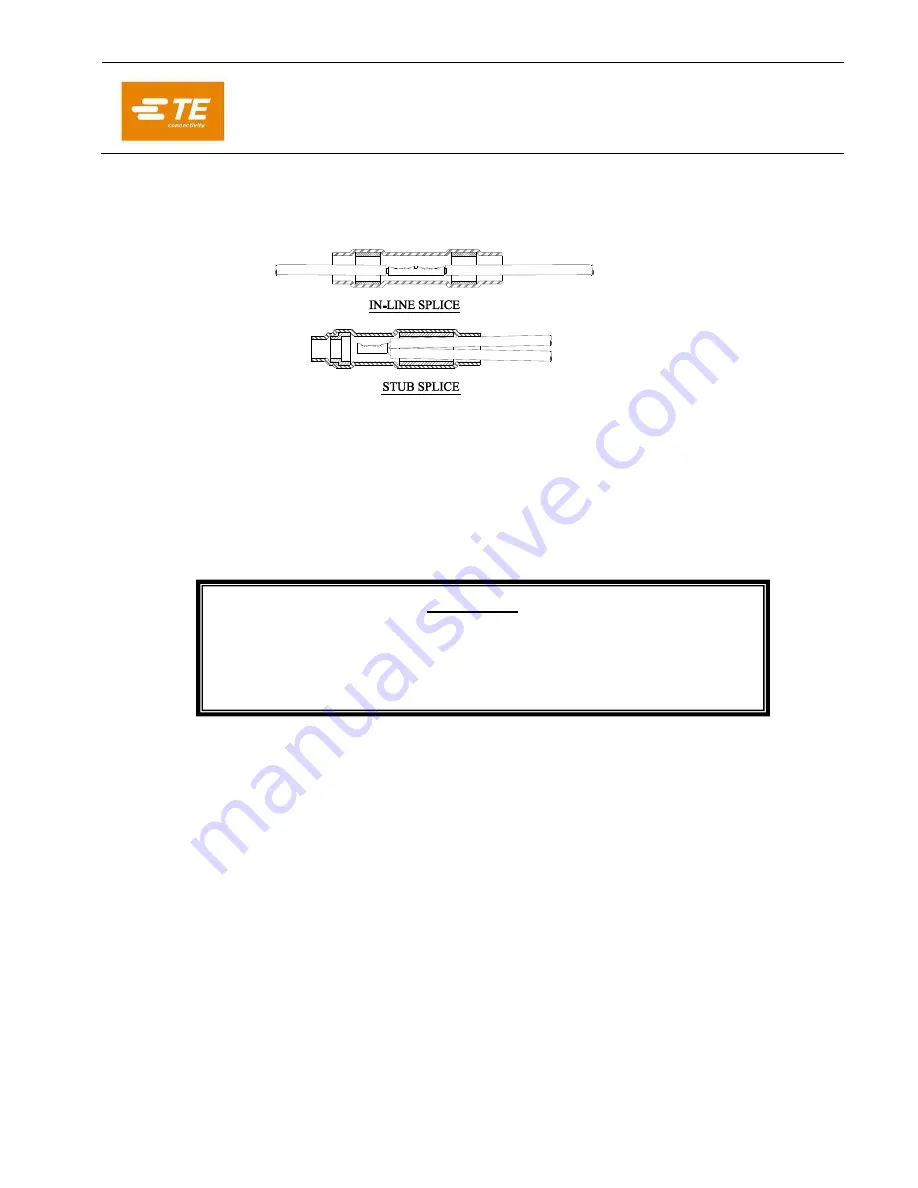

Installation Procedures for D-436-XX and D-200-XX

(Miniseal™) Sealed Crimp Splices

_________________________________________

Unless otherwise specified dimensions are in millimeters. [Inches dimensions are in between brackets]

© 2007-2016 TE Connectivity Corporation. All rights reserved.

If this document is printed it becomes uncontrolled. Check for the latest revision.

(4) Heat (see Warning note) the sealing sleeve to shrink it and melt the seals as follows:

a. Use one of the heating tools listed in section 3.

b. Heat from one end toward the other. For stub splices, start at the end from

which the wires exit.

c. Continue heating until the seals melt and flow along the wire insulation and if a

stub splice, one seal melts and closes the end.

d. Allow the assembly to cool undisturbed.

WARNING

The heating tool and the assembly become hot during the installation of

the Sealing Sleeve. To prevent burns, allow tool and the assembly to cool

down before handling.

(5) Inspect the completed sealed splice per section 6.

5.4

Multiple-to-one In-line Splices and Multiple-wire Stub Splices

5.4.1.

Select proper slice components and prepare the wires as shown. (See 5.0.1, 5.0.2)