Raychem Devices

No: RCPS-200-20

Rev: E1

Date: August 10, 2016

Installation Procedures for D-436-XX and D-200-XX

(Miniseal™) Sealed Crimp Splices

_________________________________________

Unless otherwise specified dimensions are in millimeters. [Inches dimensions are in between brackets]

© 2007-2016 TE Connectivity Corporation. All rights reserved.

If this document is printed it becomes uncontrolled. Check for the latest revision.

1.

Scope:

This document covers the installation procedures and inspection requirements for D-436-

XX and D-200-XX devices for making immersion-resistant crimped splices.

2.

References:

(1) MiniSeal™ Wire Splices Selection Guide (H50279 6/79).

(2) Tyco Electronics Customer Drawings (CD), D-436-XX.

(3) Tyco Electronics Customer Drawings (CD), D-200-XX

3.

Application Equipment and Tools:

3.1

Crimp Tools

(1) AD-1377 Crimp Tool.

(2) Manufacturer's recommended crimp tool for splices other than Tyco Electronics/

Raychem crimp splices.

3.2

Heating Tools

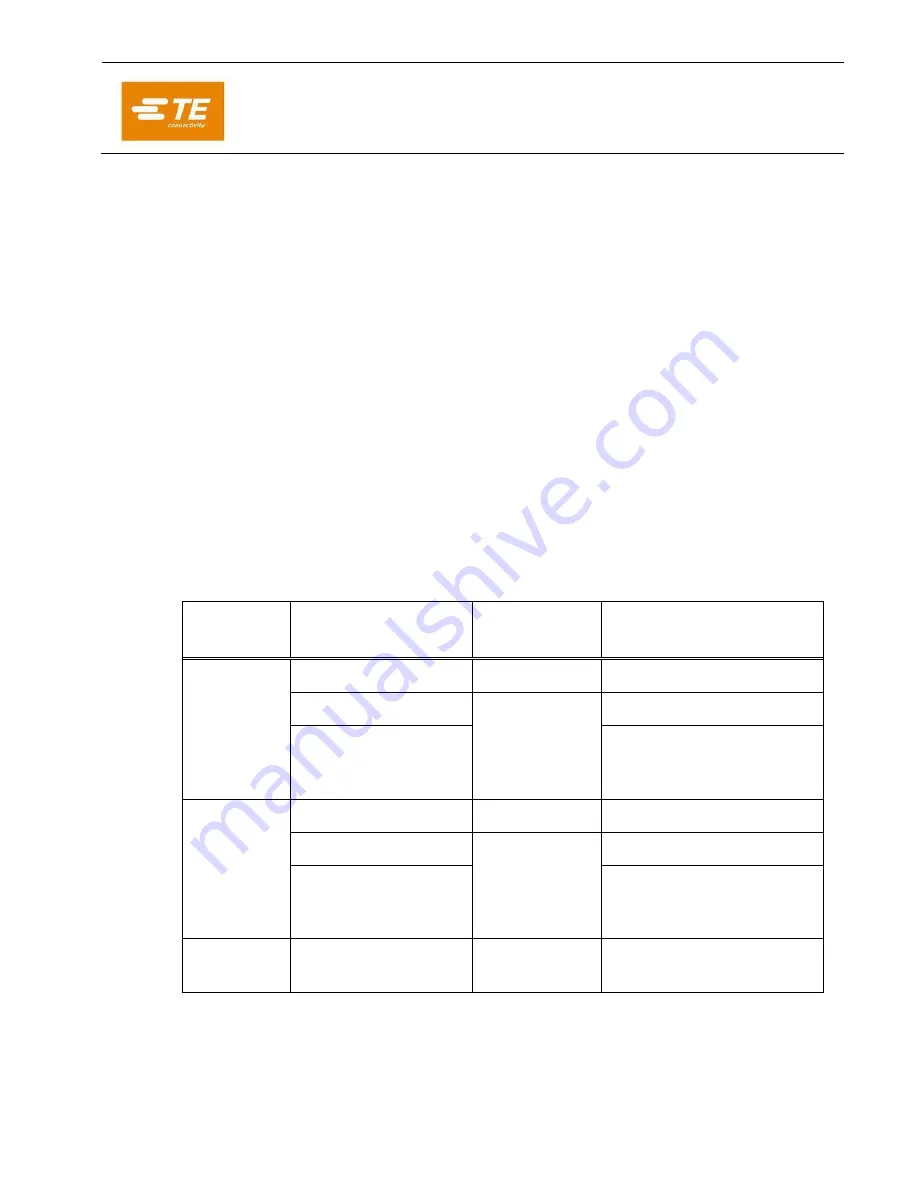

Products

Heating Tool

Reflector

Setting

D-436-XX

AA-400 Superheater

Solder Sleeve

700°F (370°C)

HL1910E

PR-25D-

REFLECTOR

with HL-1802E-

ADAPT-PR or

HL1802E-07616

REFLECTOR

6 on dial

(1)

HL2010E

700°F (370°C) on LCD

(1)

D-200-XX

AA-400 Superheater

Solder Sleeve

750°F (400°C)

HL1910E

PR-25D-

REFLECTOR

with HL-1802E-

ADAPT-PR or

HL1802E-07616

REFLECTOR

7 on dial

(1)

HL2010E

750°F (400°C) on LCD

(1)

D-436-XX,

D-200-XX

IR-500 or IR-550

Infrared Heater

RG-2

RG-6

N/A

Note: CV-1981 Heating Tools are suitable alternatives. See product brochure for additional details.

4.

General Information:

4.1

Description

The parts covered by this document are designed for making immersion resistant crimped

splices in wires rated for at least 135

C. This procedure covers crimp splices for making