EPP-1988-INT-7/13 20/20

NL

;;;;;;;;;;;;;

;;;;;;;;;;;;;

;;;;;;;;;;;;;

;;;;;;;;;;;;;

6 W

8 W

;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;

;;;;;;;;;;;;;;;;;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

;

7 W

Marking line

Joint completed.

Allow the joint to cool before applying any mechanical strain.

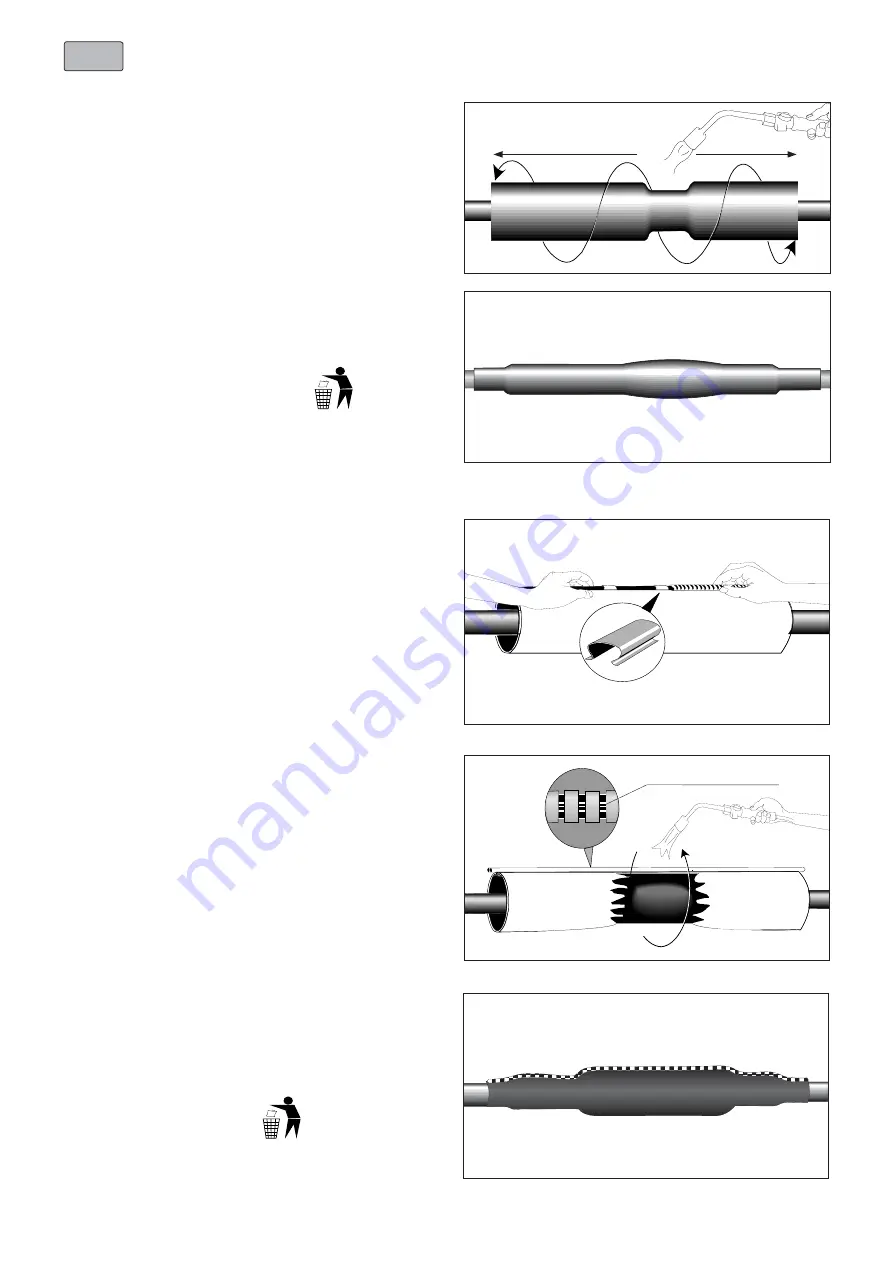

OPTION S:

Installation using

Outer Seeling Sleeve

Clean the cable jackets on both cable ends and abrade them

for a distance of at least 150 mm.

Position the outer sealing sleeve centrally over the joint area.

Control the equal overlap on both cable jackets.

Shrink down the outer sealing sleeve, starting over the

connector area (outside the center), working towards the

ends.

OPTION W:

Installation using

Wraparound Joint Sleeve

Clean and degrease 150 mm of the oversheath on the plastic

cable end.

Remove the inner protective plastic and position the

wraparound joint sleeve centrally over the joint covering the

oversheath to the same extent on both cable sides.

Press the retention clips over the rail of the wraparound to

keep it in place.

Push the metal channels over the rail of the wraparound.The

end of the metal channel should butt up and equally overlap

the retention clips.

After all channels have been pushed on they should overlap

the wraparound equally on both sides.

Please dispose of all waste

according to environmental

regulations.

Joint completed.

Allow the joint to cool before applying any mechanical strain.

Please dispose of all waste

according to environmental

regulations.

Shrink the wraparound sleeve into place starting at the

middle of the joint. When the colour of the paint on the

wraparound has completely changed to black progressively

move towards the ends.

Note:

Extra heat is required on the metal channel. Heat until

the marking line (white) on the rails can be seen under the

channels.

Place metal ZIP along the cable core, this will support the

ZIP when heating.

6 S

7 S