Tyco Electronics Corporation

300 Constitutional Drive

Menlo Park, CA 94025 USA

No: RPIP-824-00

Rev: F

Date: April 28, 2006

Page: 10 of 11

© 2005-2006 Tyco Electronics Corporation. All rights reserved.

Unless otherwise specified dimensions are in millimeters [Inches dimensions are in between brackets]

If this document is printed it becomes uncontrolled. Check for the latest revision.

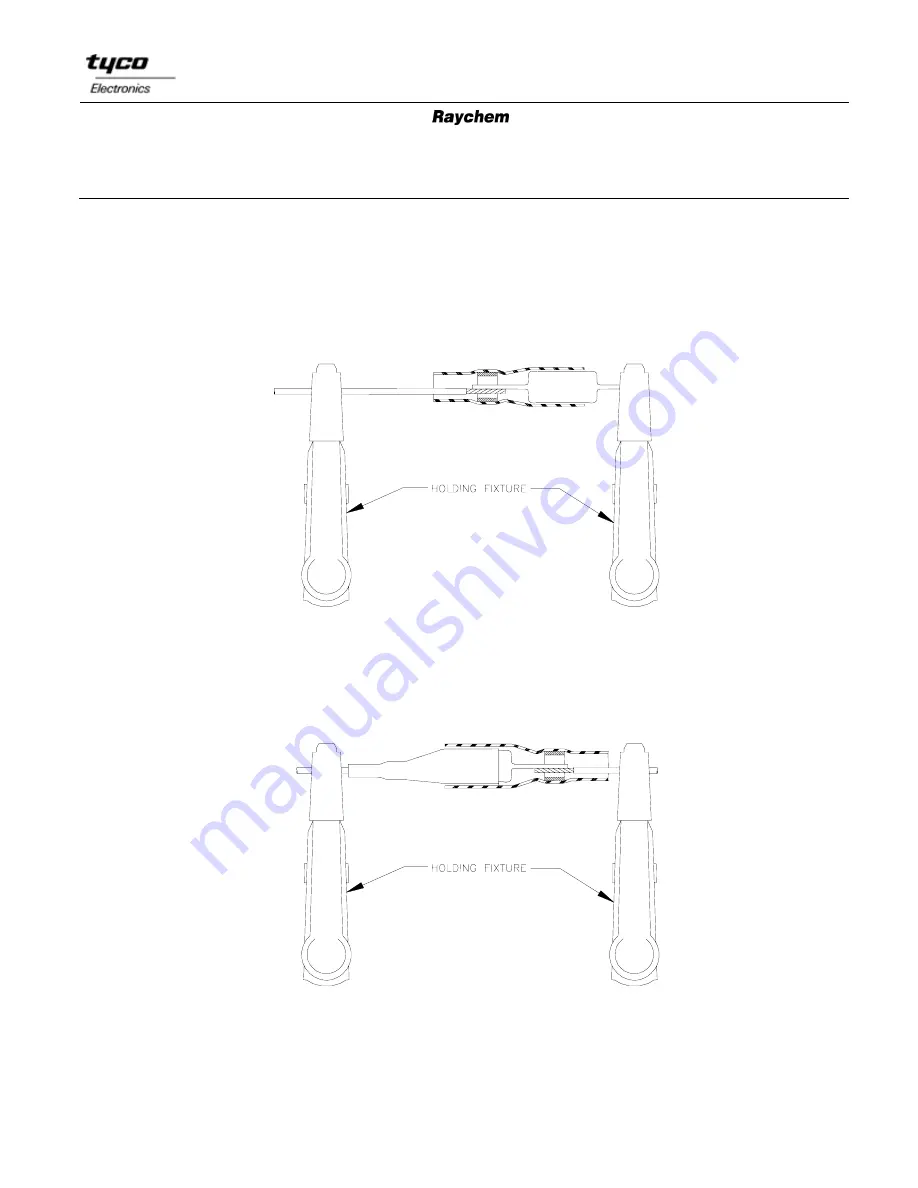

4.5.2 Assembly

1. Overlap the exposed conductor and the component pin and position the CWT-200X-A

or B-155-200X-A sub-assembly so that the solder preform is centered over the conductors.

2. Use a holder to keep the wire and component aligned during heating.

3. Heat solder preform until it melts and forms a fillet between the conductors.

4. Overlap the other exposed conductor and component pin and position the CWT-200X-B

or B-155-200X-B sub-assembly so the solder preform is centered over the conductors.

5. Use a holder to keep the wire and component aligned during heating.

6. Heat solder preform until it melts and forms a fillet between the conductors.