Tyco Electronics Corporation

300 Constitutional Drive

Menlo Park, CA 94025 USA

No: RPIP-824-00

Rev: F

Date: April 28, 2006

Page: 2 of 11

© 2005-2006 Tyco Electronics Corporation. All rights reserved.

Unless otherwise specified dimensions are in millimeters [Inches dimensions are in between brackets]

If this document is printed it becomes uncontrolled. Check for the latest revision.

WARNING

The heating tool and the assembly become hot during the installation of

the SolderSleeve One-Step Wire and Cable Terminators. To prevent burns,

allow tool and the assembly to cool down before handling.

4.1 Shield

Terminations

4.1.1 Cable

Preparation

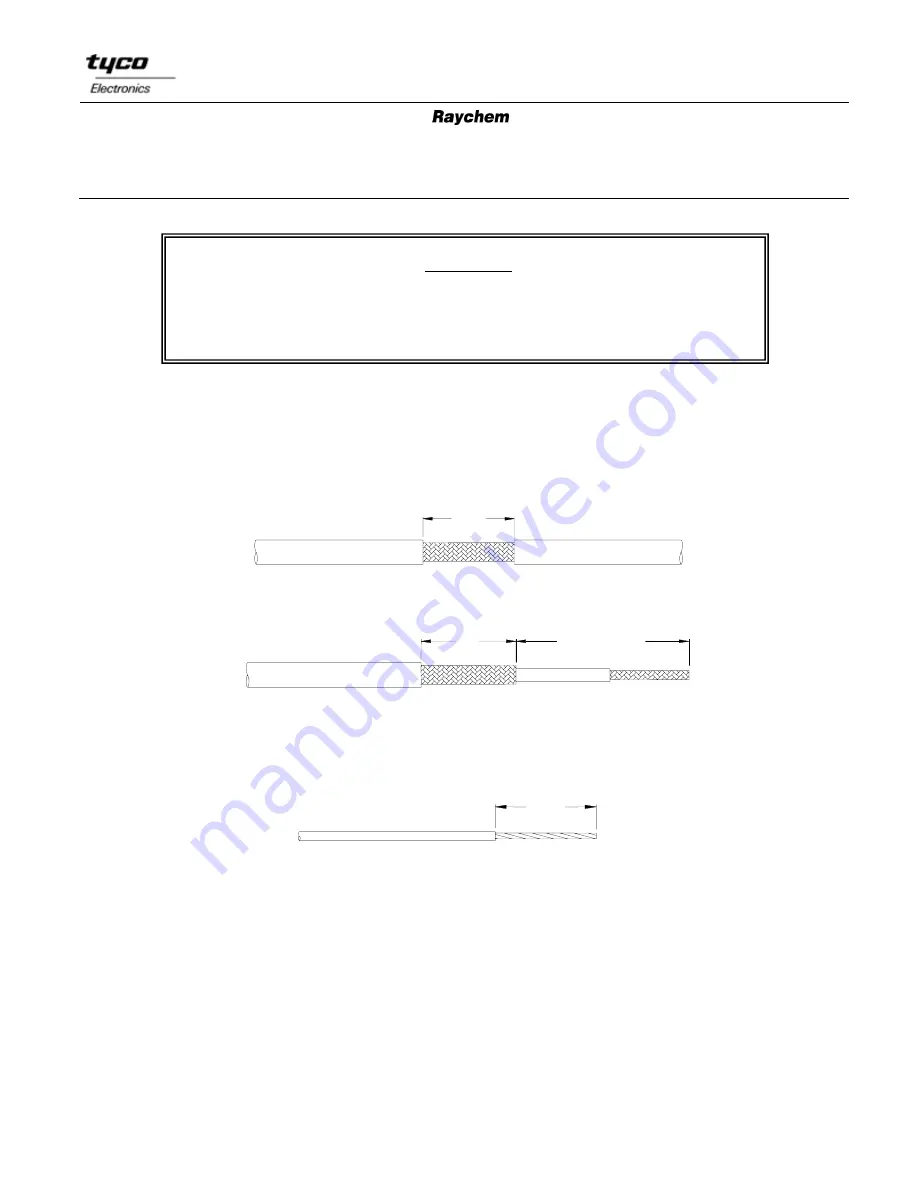

1. Remove length specified in Table I of the cable jacket at the point where the termination is

to be made.

A

Center Stripped

A AS REQUIRED

End Stripped

2. Remove length specified in Table I of insulation from the end of the ground lead. (If part

has pre-installed lead, omit this step.)

B

4.1.2 Assembly

1. Position the one-step soldersleeve shield terminator so that the solder preform is centered

over the exposed shield.

2. Position the lead to be attached between the solder and the exposed shield.

3. Allow the application equipment to reach the operating temperature.

4. Place the assembly centrally in the reflector.

5. Heat the solder preform until it melts and forms a fillet between the lead and the shield.