Tyco Electronics Corporation

300 Constitutional Drive

Menlo Park, CA 94025 USA

No: RPIP-824-00

Rev: F

Date: April 28, 2006

Page: 3 of 11

© 2005-2006 Tyco Electronics Corporation. All rights reserved.

Unless otherwise specified dimensions are in millimeters [Inches dimensions are in between brackets]

If this document is printed it becomes uncontrolled. Check for the latest revision.

Table I

. Cable Jacket and Wire Insulation Stripped Length.

RoHS Compliant

Shield Terminator

Shield Terminator

Size

A

±

0.5

[±0.002]

B

±

0.5

[±0.002]

Minimum

Overlap

3

7.0 [0.276]

6.0 [0.236]

5.5 [0.217]

5

9.0 [0.354]

8.0 [0.315]

7.0 [0.276]

6

10.0 [0.394]

9.0 [0.354]

7.5 [0.300]

7

11.0 [0.433]

10.0 [0.394]

8.5 [0.335]

9

12.0 [0.472]

11.0 [0.433]

9.0 [0.354]

11

13.0 [0.512]

12.0 [0.472]

10.0 [0.394]

B-155-XX

B-155-XX-1000

B-155-XX-35-22-5

B-155-XX-35-22-9

CWT-XX

CWT-XX-1000

CWT-XX-W122-5

CWT-XX W122-9

13

17.0 [0.670]

16.0 [0.630]

14.0 [0.551]

3, 5

7.0 [0.276]

6.0 [0.236]

5.5 [0.217]

B-155-XX-S CWT-XX-S

7, 11

9.0 [0.354]

8.0 [0.315]

7.0 [0.276]

B-155-15XX

B-155-38XX

B-155-XXXX-WX

CWT-15XX

CWT-38XX

CWT-XXXX-WX

All

12.5 [0.492]

12.5 [0.492]

9.5 [0.374]

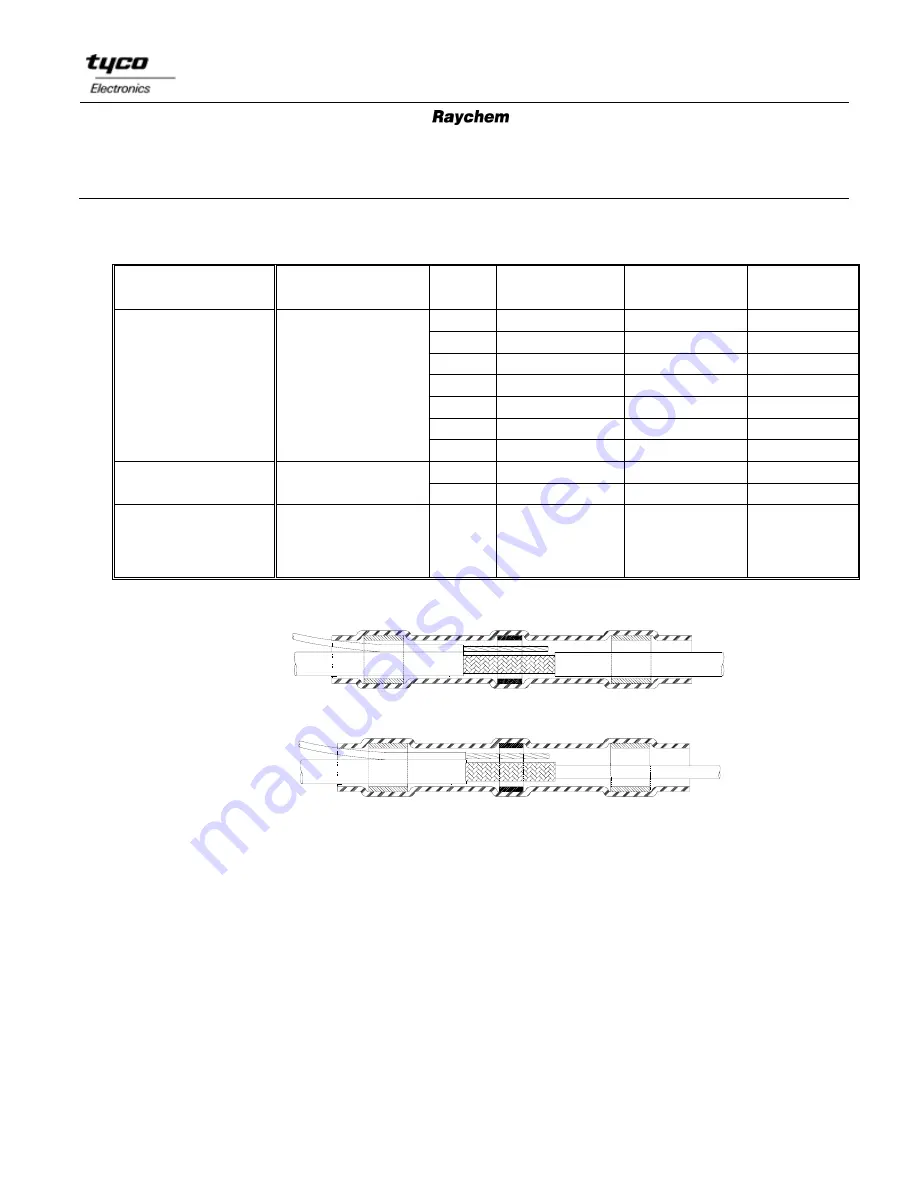

Center Stripped

End Stripped

4.1.3 Inspection

1. Positioning: The ground lead conductor should overlap the shield minimum length specified

in Table I.

2. Heating: The solder ring shape should not be visible and a solder fillet, at least 4.5 [0.188]

long for CWT-15XX, CWT-38XX and CWT-XXXX-WX, B-155-15XX, B-155-38XX and

B-155-XXXX-WX, should be visible on one side of the lead. Lack of a solder fillet may

indicate overheating.

3. Damage: The sleeve should not be split or cut and no wire strands should poke through the

sleeve.