Te Pari - www.tepari.com - FREEPHONE 0800 837 274

HD3 Sheep Handler Installation Manual

1214-V1

6

Racewell HD

SHEEP HANDLING SYSTEMS

THE COMPRESSOR

We recommend a 12cfm belt driven compressor, if the compressor is too small the

Racewell will run slowly and may not operate properly

The compressor does not need to be close to the Racewell in fact having it at some

distance reduces noise levels in the working area It is important to run compressors in a

well ventilated area as close as possible to a main supply near a switchboard - this avoids

the use of leads which can affect the power input From time to time the oil level on the

dipstick should be checked and the water drained from the air reservoir

Please Note: When turning the compressor on or off use the switch on the compressor.

Do not turn on or off at the power source switch.

This applies to all compressors, because air is not discharged, the compressor is being asked to start

under load and this can burn out its capacitor

ATTACHING THE AIR FITTINGS AND COMPRESSOR HOOK UP

Pipe the air to the compressor to the unit via standard 15mm (1/2 inch) alkathene water

line We have some units working with the compressor up to 2kms from the work site

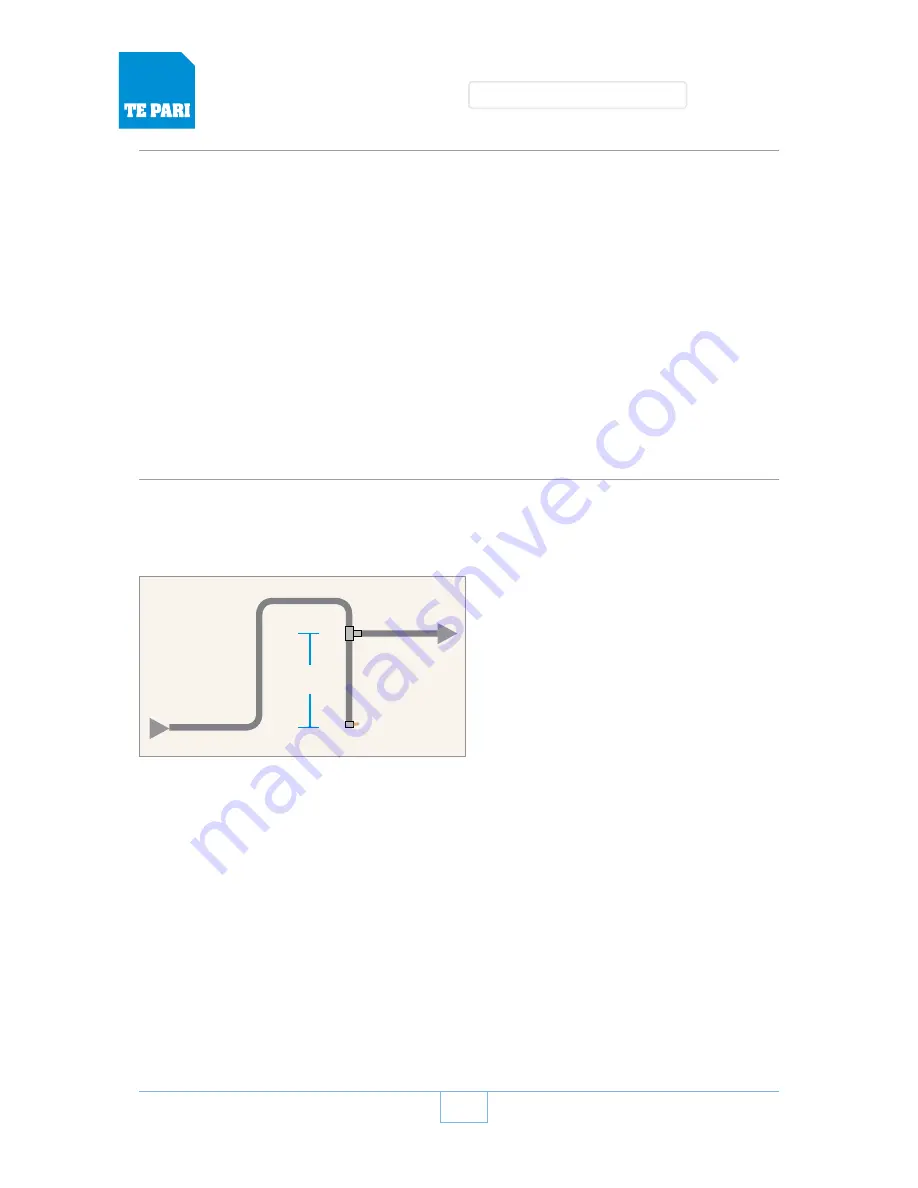

If your compressor is situated some

distance from your Racewell we

recommend the airline configuration

shown here

This provides a purge tap or ball valve

so that condensation can be periodically

removed from the air system

Assemble the airline and connect to the

compressor Plug the compressor into a

power source and turn the power source on, then using the switch on the compressor turn

the compressor on Always turn the compressor on or off at the compressor, not the wall

The 3 pin socket on the power pack situated under the sheep unit can now be connected

to the power source The airline from the compressor (female end) can now be plugged

into the male fitting on the underside of the sheep unit This is on the same side as the

power pack was plugged in It is just inside the frame, toward the back

Using the Hoist Switch on the dashboard or the manual hoist lever under the floor section,

carefully tilt the unit Disconnect the air from the sheep unit You now have access under

the unit Non-tilt options are tilted for access by hand, just lift up until the weight is taken

on the safety chain

From your

Compressor

To your

Racewell

Ball or tap valve

1 metre

(approx)