Energy 2510 B

Vers. 001

GB

24

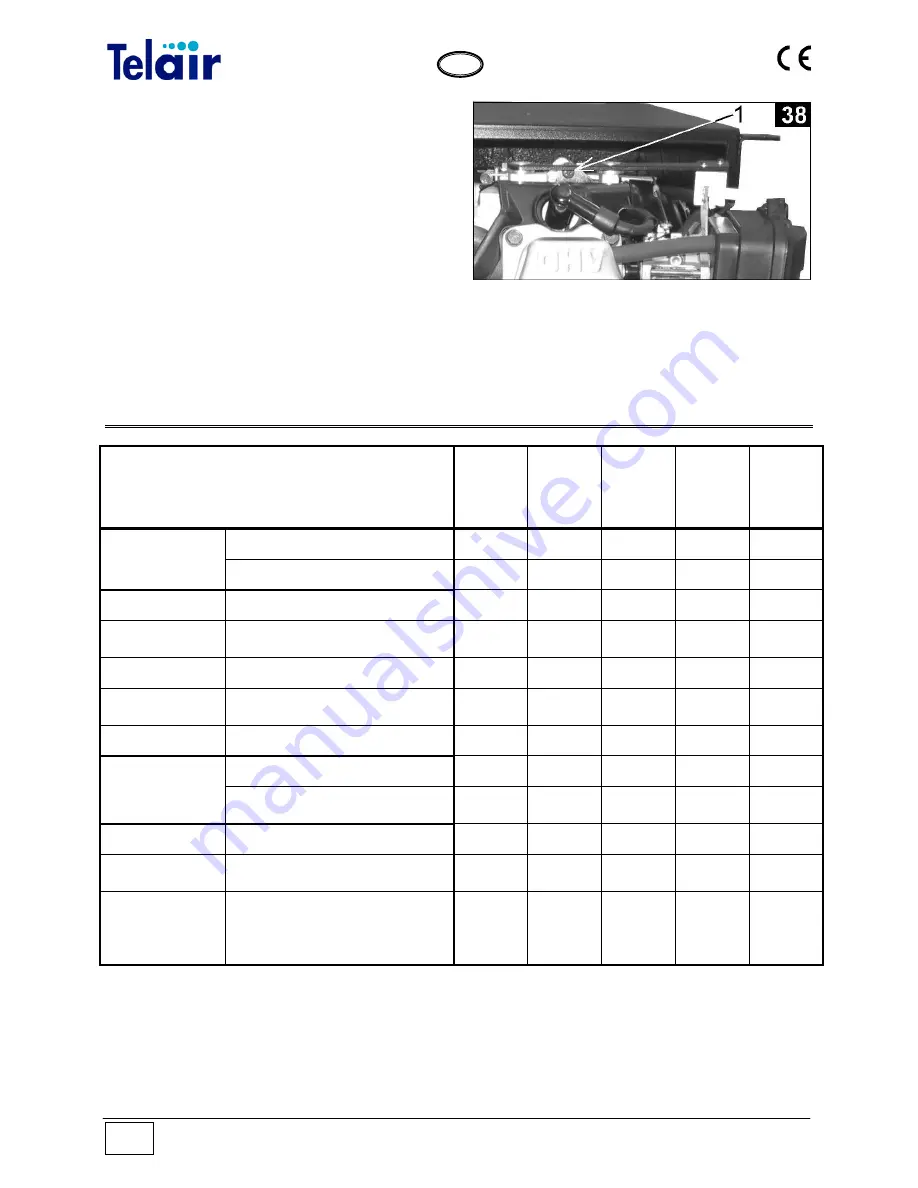

Check the voltage of the generating set using a

voltmeter via a 230 V vehicle socket. The voltage

must be between 230 V and 245 V without any

connected user.

If different values are measured, it will be

necessary to set the right values by working on

the engine rpm adjustment screw (Fig.38 Ref.1).

Turn the screw clockwise to increase the engine

rpm and consequently, the voltage.

Turn the screw counter-clockwise to decrease

the engine rpm and consequently, the voltage.

8 ROUTINE MAINTENANCE SCHEDULE

ROUTINE MAINTENANCE SCHEDULE

To be performed after the period of time or the number

of running hours listed here, whichever the earlier

.

Every

use

First

Month

or

20 hours

Every

3 Months

or

50 hours

Every

6 Months

or

100 hrs

Every

12 Mths

or

300 hrs

Level check

■

Engine Oil

Replacement

■

(2)

■

(2)

Air Filter

Clean and replace if necessary

(1)

■

(2)

Fuel Filter and

Tank

Clean and replace if necessary

■

(2)

Spark plug

Clean and replace if necessary

■

(2)

Valve

Adjustment

Check - Adjust

■

(2)

Fuel Pipe

Check for leaks or cracks

■

(2)

Check for leaks or cracks

■

(2)

Muffler

Clean and replace spark

screen if necessary

■

(2)

■

(2)

Air Choke Valve Check correct operation

■

(2)

Engine rpm or

Frequency

Check - Adjust

■

(2)

Vibration

Damper

Suspension

Points

Check – Replace if necessary

■

(2)

NOTES: (1) Clean more frequently if you use it in a very dusty environment

.

(2) These operations must be performed by specialised personnel only.

Summary of Contents for Energy 2510B

Page 29: ...Vers 001 Energy 2510 B 29 GB DRAWING FOR SPARE PARTS LIST ENERGY 2510 B ...

Page 30: ...Energy 2510 B Vers 001 30 GB ...

Page 31: ...Vers 001 Energy 2510 B 31 GB ...

Page 39: ...Vers 001 Energy 2510 B 39 GB Notes ...

Page 40: ......