P9

P17 x 2

B13

P10

R ed C ap

( Sm all)

45

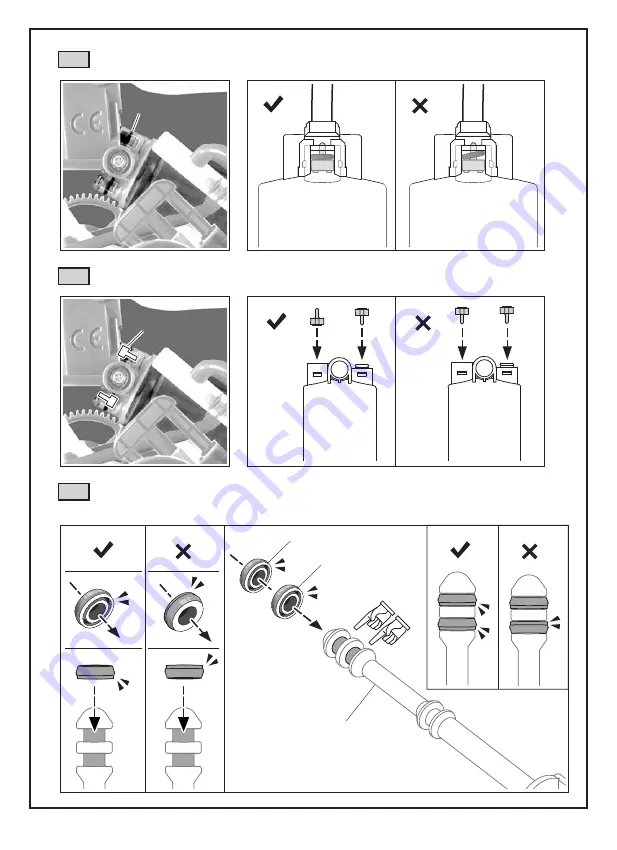

1- 8 C heck if P10/ B13 are inst alled in the correct direction.

( ref er to p age 22, st ep s 11~ 13)

1- 7

C heck if P17 is inst alled in the right direction. ( ref er to p age 12, st ep 3 )

1- 6

C heck if P9 ( O - ring) is se ated f lat. ( ref er to p age 12, st ep 6 )

C orrect

I ncorrect

C orrect

I ncorrect

C orrect

I ncorrect

C orrect

I ncorrect

Summary of Contents for AIR SCREAMER

Page 1: ...Discovery From the Makers of TTG 631 10 ASSEMBLY INSTRUCTION MANUAL ...

Page 21: ...P1x4 C1 19 4 5 2 Scale 1 1 1 ...

Page 23: ...D13 21 10 D13 9 Gently tap D13 with hammer to the bottom as shown below Incorrect ...

Page 28: ...26 17 4 2 3 1 1 Route the air tube to the position as shown above Correct Incorrect ...

Page 29: ...Make sure the airtube is facing the correct direction 27 18 19 P1x4 2 4 3 Scale 1 1 1 5 1 ...

Page 30: ...D17 1 28 20 21 1 1 2 2 Scale 1 1 P1 B4 ...

Page 32: ...30 23 24 Correct Incorrect ...

Page 33: ...1 31 25 4 3 2 1 ...

Page 34: ...D6 C4 32 26 27 2 3 2 4 5 1 1 6 1 P19 P19 02 02 ...

Page 35: ...Scale 1 1 P1x5 33 28 29 Top View Correct Incorrect ...

Page 36: ...34 30 1 3 4 2 Ensu re the correct direction of air tu be C orrect I ncorrect ...

Page 37: ...D19 D18x2 35 B6 P18 1 2 2 31 32 D10 1 ...

Page 40: ...2 38 B9 P18x5 37 39 38 Make sure there is no oil on connector for assembly ...

Page 41: ...B5 B5 39 B12 P18x5 P7 40 41 Correct Incorrect Correct Incorrect ...

Page 42: ...1cm B11 40 P18x5 42 43 ...

Page 43: ...4 1 F i n i sh ed P 19 P 19 06 07 44 ...

Page 50: ...48 Notes ...

Page 51: ...49 Notes ...