11.8 Discharging Square Bales

Gradually increase bed chain speed by means of the

speed control until shredding commences. It is then

advisable to increase bed chain speed to a point at which

the slices of the bale being shredded are forced up and

over the material coming forward. This rotational motion

is represented in Figure 6.

Where a bale lift is fitted to a Tomahawk 1010, release

the portion of the bale retained by the bale lift only when

the first portion has been discharged which is usually

indicated by a large fall in discharge rate.

Once the material in the bale chamber has been

discharged the tailgate can be lifted to allow a portion of

rear half of the bale to be loaded into the chamber thus

allowing room for the material in the bale chamber to

rotate.

With a Tomahawk 1010 it will be found advantageous to

only allow half of the second bale to enter the chamber at

a time thus allowing room for each half to rotate.

Typically the rate of discharge may be controlled by bed

chain speed but only once rotation of the material within

the body of the machine has been achieved.

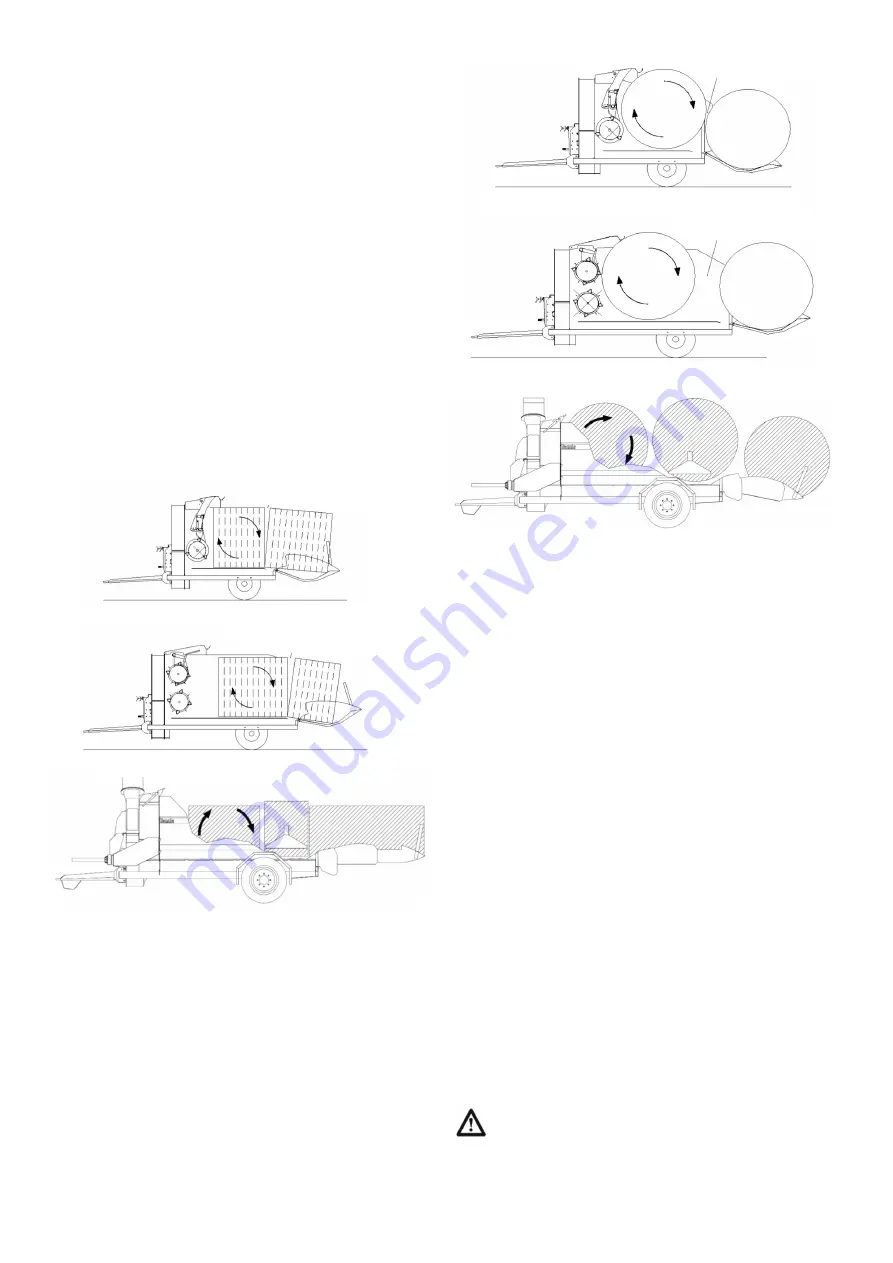

Figure 6. Rotation of square bales

11.8 Discharging Round Bales

Gradually increase bed chain speed by means of the

speed control until discharge commences. Good

performance will only be achieved by getting the bale to

rotate within the chamber as shown in Figure 7.

Increasing the speed of the bed chain will increase the

rate of discharge until a maximum rate is achieved. If the

bed chain speed is too great, material will unroll from the

bale at a rate greater than can be discharged. This will be

indicated by a build up of material above the crossbeater

bale restraint.

Figure 7. Rotation of round bales

11.9 Discharging Clamp Silage

Increase bed chain speed until the desired discharge rate

is achieved. Once the forward portion of the load has

been discharged, the tailgate can be lifted to ensure a

continuous feed rate.

11.10 General Discharging Instructions

If a large amount of loose material builds up above the

bale restraint it may be necessary to reverse the bed

chain until the loose material falls down behind the

crossbeater(s) before recommencing discharge.

When it is necessary to stop shredding part way through a

bale, always stop the bed chain rotation and put it in

reverse for a few seconds before stopping the rotor and

crossbeater(s). This allows the material in the area

around the crossbeater(s) and rotor to be blown clear of

the machine. Failure to do this may result in a blockage

when the machine is re

-

started.

The length of chop, evenness of feed and power

consumption will vary with the condition of the bale. In

general, baled silage and damp or caked straw materials

will require a higher power input than dry brittle materials.

Should the rotor or crossbeater(s) become blocked,

indicated by either slipping of the PTO clutch or failure of

the crossbeater(s) shear bolt, it may be necessary to turn

the rotor backwards. This may be achieved by levering

the rotor paddles with a post through the outlet chute.

Further access may be gained by removing the blockage

panels from the front of the upper and lower rotor

housing.

CAUTION.

DUAL CHOP: Always fully raise the

blade carrier and lock it in position with pins before

attempting to remove blocked material from the

crossbeater.

20

1010 models

7100, 7150, 8100, 8150, 8500 & 8555 models

9500 models

Gap between bales

Gap between bales

7100, 7150, 8100, 8150, 8500 & 8555 models

9500 models

Gap between front and rear

1010 models

Gap between front and rear

Summary of Contents for Tomahawk 7100

Page 1: ...30417 10100 11 19 30970 10345 31725 11338 10056 3694 TMKBXOP1119A...

Page 38: ...NOTES 35...

Page 39: ...36 NOTES...

Page 40: ......