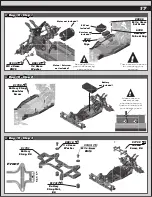

11

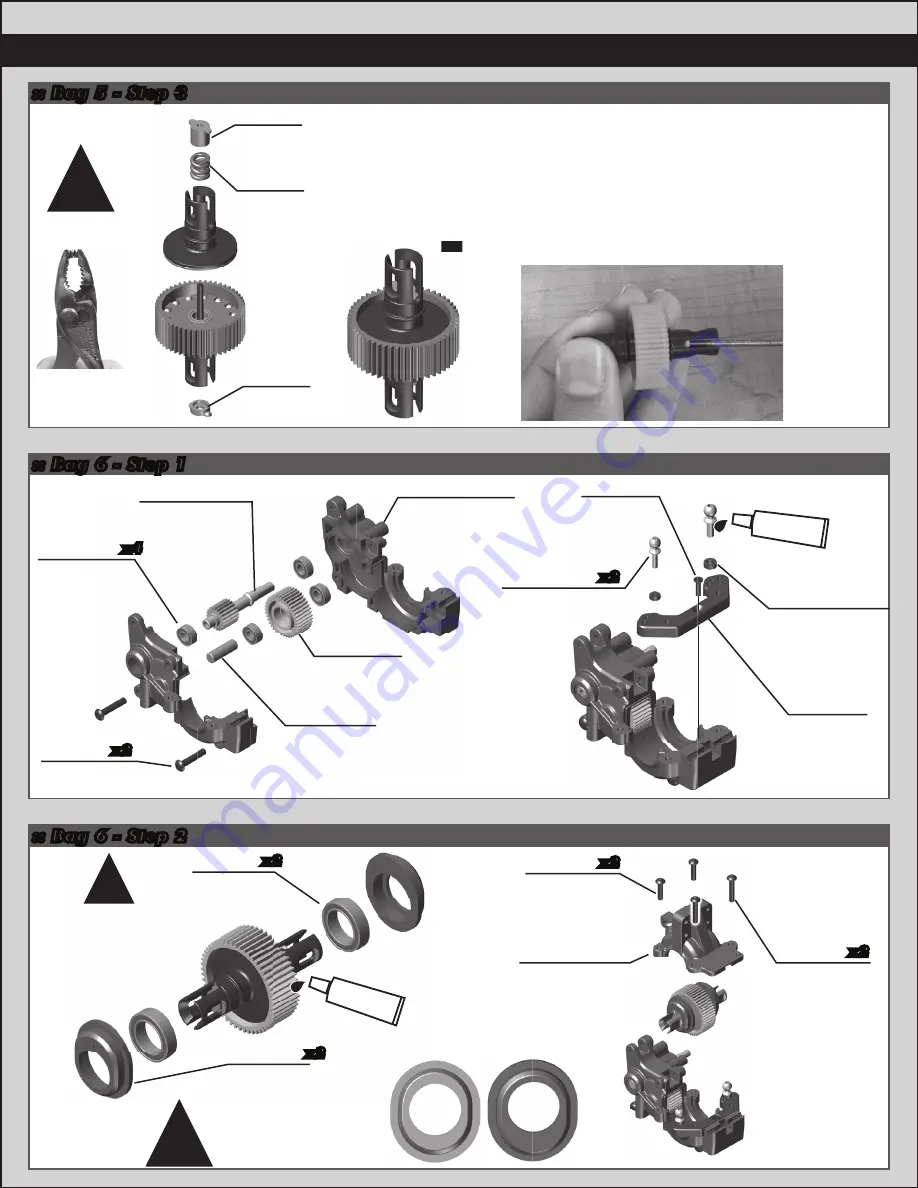

:: Bag 6 - Step 2

:: Bag 6 - Step 1

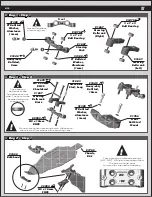

:: Bag 5 - Step 3

As you tighten the diff bolt, you will notice the T-nut ears moving

closer to the bottom of the outdrive slot. This compresses the

spring behind the T-nut. The spring should be completely

compressed at the time the T-nut reaches the end of the slot.

Caution! Pay close attention to the feeling when the spring is

completely compressed. Do not overtighten the bolt. When you

feel the spring completely compressed, loosen the diff bolt 1/8”

of a turn. Your diff should now operate smoothly but with

resistance as the outdrives move in opposite directions.

After you have driven the car once, re-check the diff setting.

6575

Diff

cover

6575

Locking

t-nut

6582

Diff

thrust

spring

Compress

spring first.

!

#6591

diff lube

Add a drop of Diff

Lube (#6591) to

the teeth of the diff

gear, idler gear, and

top shaft.

!

91792

B6.1 Diff

Height Insert

91563

10x15x4

Bearing

x2

x2

!

2

1

3

0

Diff Height Inserts:

The number on top

is the setting.

Stock diff height is 0.

91791

B6.1 Laydown

Gearbox

(right & left)

91560

5 x 10 x 4,

Bearing

89203

3x16mm

BHCS

31448

2.5x8mm

FHCS

91716

Idler Gear

39T

91799

B6.1 Laydown

Top Shaft

91132

Idler Gear

Shaft,

Aluminum

x4

x2

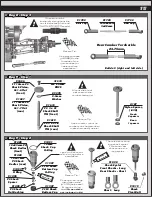

91048

Heavy-duty

Ballstud, 8mm

x2

91775

B6.1 Rear

Ballstud

Mount,

Aluminum

31383

Ballstud

Washers,

5.5x2.0mm,

Blue Aluminum

89202

3 x 12mm

BHCS

91791

B6.1 Laydown

Gearbox Top

89203

3 x 16mm

BHCS

x2

x2

#1596

thread lock