:: Tuning Tips

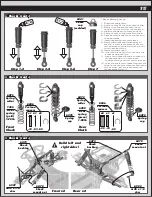

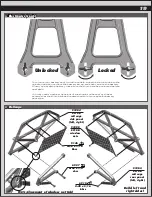

Slipper Clutch:

The assembly instructions give you a base setting for your slipper clutch. Turn the nut on the shaft so that the end of

the top shaft is even with the outside of the nut. Tighten the nut 3 more turns. At the track, tighten or loosen the nut in

1/8 turn increments until you hear a faint slipping sound for 1-2 feet on takeoffs.

Another popular way to set the clutch is to hold both rear tires firmly in place and apply short bursts of throttle.

If the clutch is properly set, the front tires should lift slightly up off the surface.

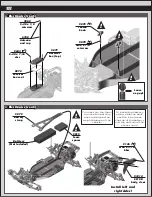

Parts Maintenance:

Periodically check all moving suspension parts. Suspension components must be kept clean and move freely without

binding to prevent poor and / or inconsistent handling.

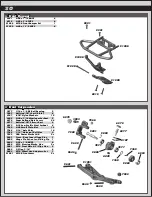

Caster:

The vehicle comes with 30 degree caster blocks (#7922). For less aggressive steering try the optional 25 degree

caster blocks (#7919).

Front Toe-In:

Zero degrees toe-in (tires pointing straight forward) is the setting that should be used in almost all track conditions.

Occasionally, adding a little bit of toe-out (tires pointing slightly out) can increase initial turn in response. A slight amount

of toe-in will increase front end stability a little and results in less aggressive steering, but this option is rarely used.

Tips for Beginners:

Before making any changes to the standard setup, make sure you can get around the track without crashing. Changes

to your vehicle will not be beneficial if you can’t stay on the track. Your goal is consistent laps.

Once you can get around the track consistently, start tuning your vehicle. Make only ONE adjustment at a time, testing

it before making another change. If the result of your adjustment is a faster lap, mark the change on the included setup

sheet (make addtional copies of the sheet before writing on it). If your adjustment results in a slower lap, revert back to

the previous setup and try another change.

When you are satisfied with your vehicle, fill in the setup sheet thoroughly and file it away. Use this as a guide for future

track days or conditions.

25

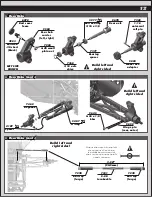

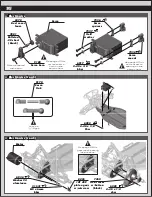

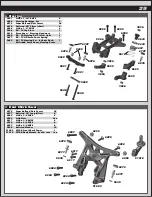

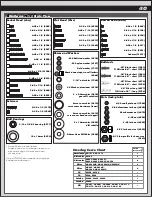

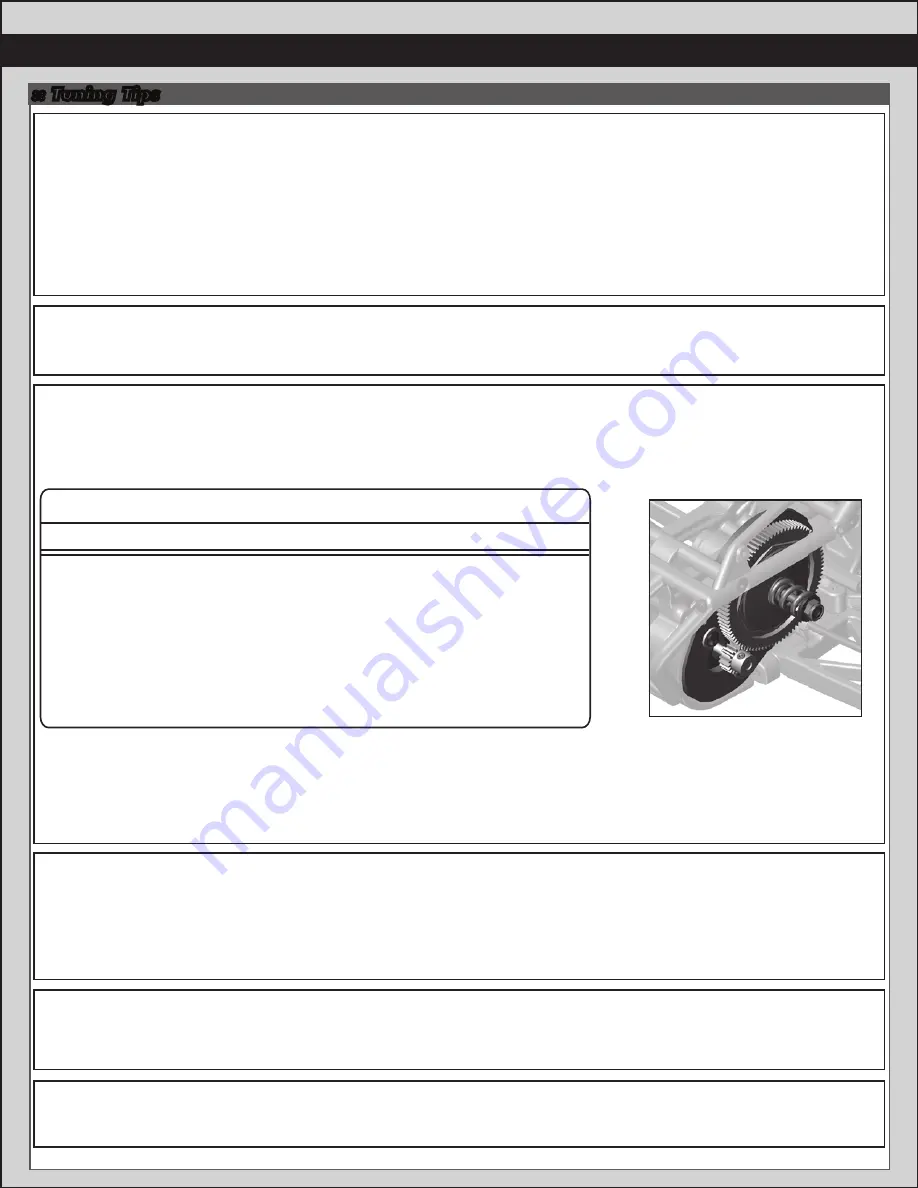

Setting Gear Mesh:

You should be able to rock the teeth of the spur gear slightly back and forth in the teeth of the pinion gear without

making the pinion gear move. If the gear mesh is tight, then loosen the #31531 motor screws and move the motor back

a little. Tighten the motor screws, then check gear mesh again. Gear mesh that is too tight or too loose can reduce

power and damage or overheat the motor or damage the teeth of the gears.

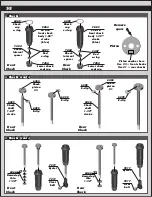

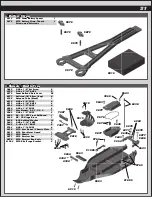

Recommended Gearing:

Proper motor gearing will result in maximum performance and run time while reducing the chance of overheating and

premature motor failure. The gear ratio chart lists recommended starting gear ratios for the most widely used

motor types. Gear ratios will vary depending upon track conditions, driving style, and personal preference.

Generally, you should not increase the pinion gear size more than one tooth greater than the starting size.

MOTOR

17.5 Brushless Motor

13.5 Brushless Motor

10.5 Brushless Motor

3300kV Brushless Motor

Pinion

28

26

24

18

Spur

75

75

87

87

SC10B Gear Ratio Chart

FDR

6.96 :1

7.50 :1

9.42 :1

12.57 :1

Summary of Contents for SC10B RS RTR

Page 1: ...10 12 ...