14

GEAR RATIO

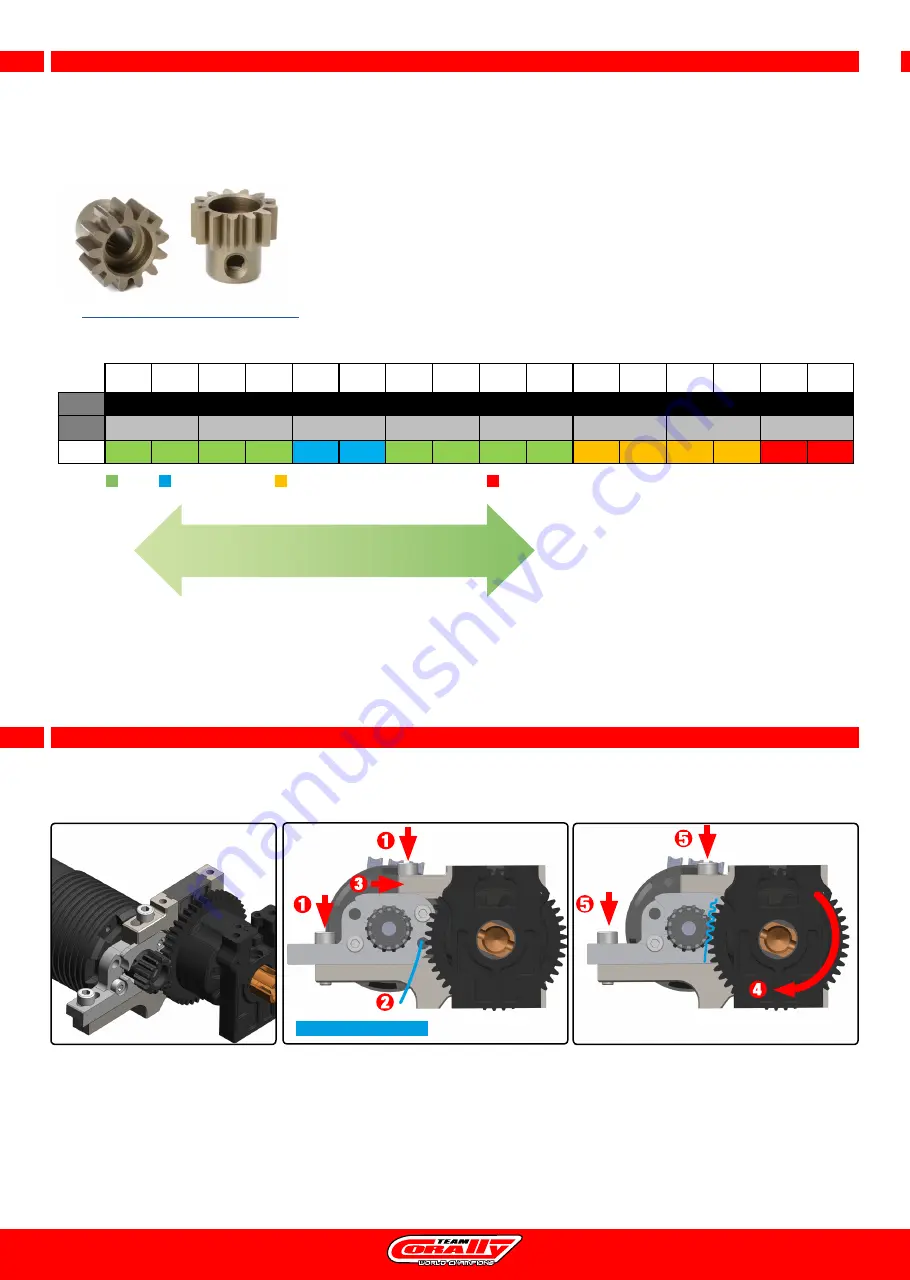

GEAR MESH ADJUSTMENT

1. Loosen the screws.

2. Insert the paper strip.

3. Push the motor against the spur gear.

4. Turn the spur gear to run the paper through

the teeth.

Stop when the paper is in the middle.

Make sure that the motor pinion is against

the spur gear.

5. Tighten the fixing screws.

If the gear mesh is not correct, you wear out the spur gear prematurely, the transmission will make noise, give unnecessary load on the

motor (higher consumption, heating of the transmission).

PAPER STRIP 1x8cm

MOTOR PINION MOD1.0

High-performance 13T tooth pinion gear, manufactured from special steel for toughness and durability with precise tolerances and assures

unparalleled concentricity. Created on a special gear machine, all pinions feature ultra-precise tooth shaping and ultra-true running for

vibration-free operation. Each pinion is marked with the tooth number for easy and quick identification.

• Special hardened steel

• CNC cut teeth for perfect teeth shape and concentricity

• Module MOD1

• fits all cars with MOD1 gears (1/8 Scale)

• for 5.0mm motor shafts

www.

corally.com/Pinions-Gears/Pinions-MOD1/

+TORQUE

+SPEED

GEAR RATIO : 3.31

OK

Factory fitted

Usable but not recommended

Not recommended, at your own risk

NOTE : The speed indicated in the table is a theoretical speed for information purposes.

The real speed varies according to the type of terrain, electronic equipment, atmospheric conditions and other driving parameters.

Km/h Mph Km/h Mph Km/h Mph Km/h Mph Km/h Mph Km/h Mph Km/h Mph Km/h Mph

Gear

11T Pinion

12T Pinion

13T Pinion

14T Pinion

15T Pinion

16T Pinion

17T Pinion

18T Pinion

46T

13,83

12,68

11,71

10,87

10,14

9,51

8,95

8,45

4S

50

31

55

34

60

35

65

40

70

43

74

46

78

49

82

51

Summary of Contents for RADIX XP 4S

Page 27: ...27...