36

SETUP GUIDE

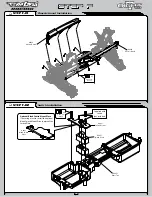

The 8IGHT-T 2.0 is equipped with the rear hub carriers in the middle. A shorter wheelbase (spacers behind the rear hubs) increases on-power

traction, rear weight transfer, and has more off-power steering. A shorter wheelbase is better on tight or slick tracks. A longer wheelbase (spacers in

front of the rear hubs) decreases off-power steering, is more stable, better in bumps, and has more on-power steering.

Sway Bars:

The 8IGHT-T 2.0 is equipped with 2.3mm sway bars on the front and rear. A thinner front sway bar increases front off-power traction, but has less

on-power steering. A thicker front sway bar decreases front off-power traction making the steering smoother entering the turn, but has more on-

power steering. A thinner rear sway bar increases rear traction and decreases on-power steering. A thicker rear sway bar increases stability in the

middle of the turn and increases on-power steering. Thicker sway bars are more stable on high-speed, high-traction tracks.

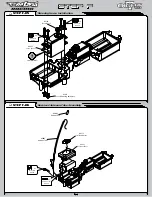

Clutch:

On new clutch bells make sure to clean the inside of the clutch bell with scouring pad or fine sand paper to improve the break-in period. Softer

springs engage at a lower rpm and have a smoother power band. If the engine doesn’t have enough low-end power try running more preload

(spring with more angle) or a stiffer spring. Stiffer springs engage at a higher rpm and hit much harder. If the springs are too stiff it will cause the

clutch to slip.

Plastic vs. Aluminum Clutch Shoes:

We have found the four aluminum clutch setup to work best on most tracks for the 8IGHT-T 2.0 but if the track is very loose, rough, and doesn’t

have jumps that are difficult to get over, two plastic and two aluminum shoes will allow more slip and smoother acceleration. Running four

aluminum shoes will have the most punch, but isn’t as good on slick tracks. Our recommended clutch setup is four aluminum shoes with two gold

springs and two green springs. Whenever you need to rebuild your clutch we recommend the following tips. First of all, be sure to clean all parts

with Losi Nitrotec™ Spray Cleaner (LOSA99217) to ensure there is no oil or debris on any of the parts. Cleaning will include all clutch parts including

the clutch bearings. We like to spray out the clutch bearings to ensure that there is no grease slung from the bearing at high rpm which would

cause premature clutch wear or slippage. When reinstalling the clutch pins we recommend NOT using any type of Losi-Lok on the clutch pins. By

using Losi-Lok on this part, it only makes it difficult to remove the pins. Once the new shoes are installed, pull back each clutch shoe 1mm to make

sure they spring back to position to ensure proper movement. You will also want to make sure the clutch bell has anywhere from .25mm to .50mm

of movement and spins freely on the crankshaft. You can use Losi’s Metric Shim Set, LOSA6356 to dial this in properly. Now that your clutch is fully

rebuilt it is time to break it in. This is done by starting your truggy and having it idle on the ground. While firmly holding the vehicle down, apply ½

throttle for three seconds. Repeat this three times to fully seat in your new clutch.

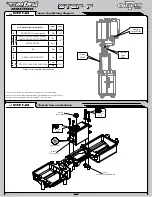

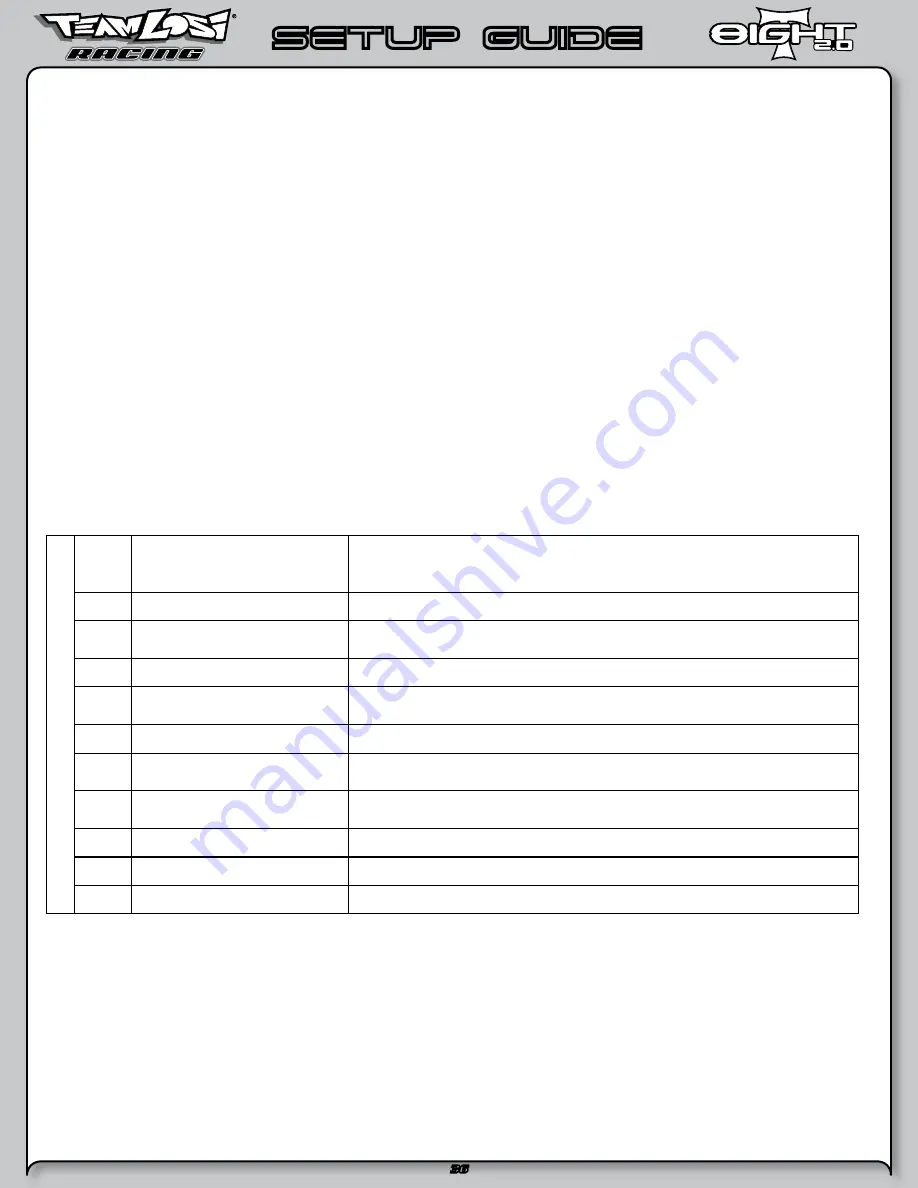

Here is a layout of clutch setups ranging from softest to hardest in acceleration

4 Plastic with Black

Clutch

Setup

Number

1

2

3

4

5

6

7

8

9

10

Shoe/Spring

Description

Ultimately the smoothest and easiest to drive setup

Used on very loose tracks where little punch is needed

Used on loose high-speed tracks where there are no jumps out of turns

Very smooth, yet has good punch. Motor must have adequate power to pull this clutch setup

Very forgiving and reduces wheel spin with punch being sacrificed slightly.

Can be used with motors that have great bottom end

Good all around setup. Best compromise for punch and mileage

Increased punch with slightly less mileage

Increased punch, good for jumps right out of turn, with average mileage.

Very aggressive with great punch, engine will run hotter and shoe life will diminish

Most aggressive, maximum punch. Use with motor that has very low bottom end

2 Aluminum with Black

2 Plastic with Black

4 Plastic with Green

2 Aluminum with Green

2 Plastic with Black

4 Plastic with Gold

2 Aluminum with Gold

2 Plastic with Green

2 Aluminum with Gold

2 Aluminum with Gold

4 Aluminum with Gold

4 Aluminum with 2 Silver and 2 Gold

4 Aluminum with Silver

Clut

ch Eng

agement S

of

test t

o Ha

rdest

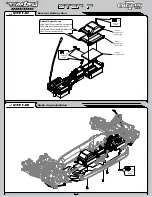

Differentials:

The 8IGHT-T 2.0 comes equipped with 7000 wt in the front, 10,000 wt center, and 2000 wt in the rear diff. Thinner front differential oil increases off-

power steering, but if the oil is too thin the steering will become grabby and inconsistent. Thicker front differential oil increases off-power stability

and increases on-power steering. Thinner center differential has less forward drive, can unload more under acceleration and is easier to drive on

rough and slick tracks. Thicker center differential has more acceleration, increases on-power steering, and less off-power steering. Thicker center

differential is better on high bite/smooth tracks. Thinner rear differential has more corning traction and increases steering in the middle of the turn.

Thicker rear differential has less steering in the middle of the turn and more forward traction.

Shock Mounting Positions:

More inclined (moving the shocks in on the tower) has softer initial damping and is more forgiving. Less inclined (moving the shocks out on the

tower) makes the car more responsive and is better for technical tracks.

Ackerman:

A long Ackerman plate will have smooth off-power steering and is more forgiving. The long Ackerman plate will have more steering on-power. A