37

SETUP GUIDE

short Ackerman plate responds quicker and has more steering in the middle of the turn. A short Ackerman plate is better suited for tight technical

tracks.

Camber:

More negative camber in the front has more steering and is more responsive. Less negative camber in the front will have less steering and will be

smoother. More negative camber in the rear will have less rear traction, but will increase on-power steering and will be less grabby in bumps. Less

negative camber in the rear will have more rear traction and make the rear of the buggy stay flatter, but if traction is lost it will be more violent. To

ensure your 8IGHT-T 2.0 has the correct camber we recommend using our Losi Camber Gauge (LOSA99172).

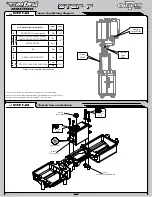

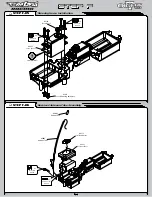

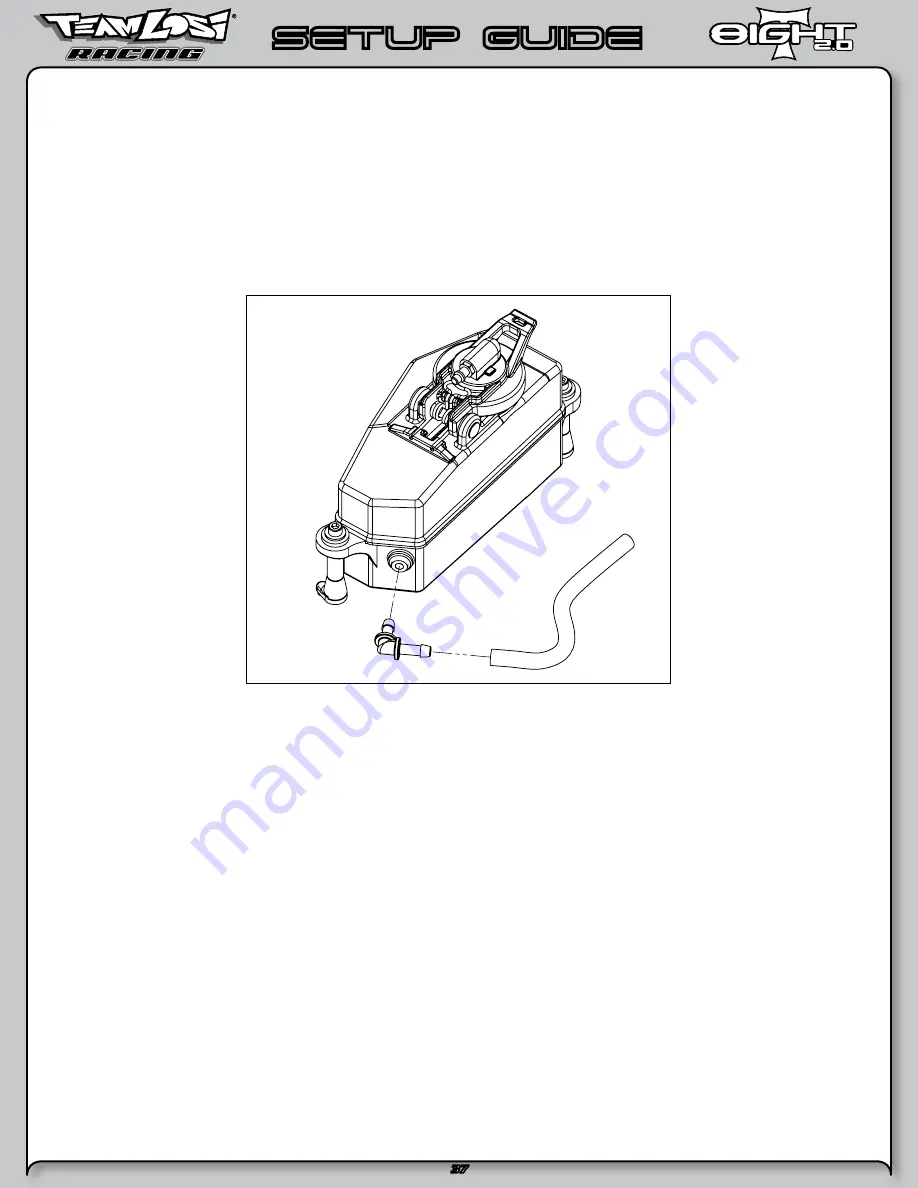

Fuel Tank:

Your 8IGHT-T 2.0 comes preinstalled with a fuel tank insert to meet ROAR and RC Pro Series 150cc fuel tank rules. If you are not racing your 8IGHT-T 2.0

where these rules apply, you can remove the insert to allow for an additional 5cc of fuel and longer run time. Also included in your 8IGHT-T 2.0 is an

EFRA Fuel Kit. This should be used at all EFRA races to ensure your fuel tank volume will not change during racing. The EFRA Fuel Kit ensures that the

fuel line and clunk does not come out of the tank, increasing fuel volume. Below is a diagram on how to install the EFRA Fuel Kit.

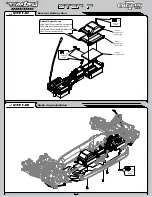

Gearing:

The stock gearing for the 8IGHT-T 2.0 is 13/50. If you are running on a large sweeping track and need more top speed, a 14-tooth clutch bell

(LOSA9117) or 48-tooth center gear is recommended.

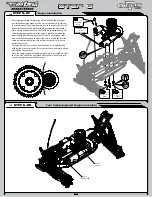

Brake Setup:

The standard brake bias for the 8IGHT-T 2.0 is 60% rear - 40% front. If you need the truck to rotate more under braking, adjust the linkage for less front

brake. If the truck is loose entering turns under braking, adjust the linkage for less rear brake or more front brake.

Outdrives and Traction:

When your 8IGHT-T 2.0 is new it will have a lot of chassis roll and be a little loose on throttle due to lack of friction in the out drives and crossbones.

After about 45-60 minutes of running, the 8IGHT-T 2.0 will gain traction and stability. Once your 8IGHT-T 2.0 is broken in, replacing the out drives and

crossbones with new parts will have more corner speed.

Bump Steer:

Running the bump steer ball down you will have smoother steering in the middle of the turn. With the bump steer ball up, this will increase steering

in the middle of the turn.

Rear Squat:

The 8IGHT-T 2.0 comes with three degrees of anti-squat. Running less anti-squat will have less off-power steering and roll (side to side) more on the

rear. Less anti-squat will accelerate better in small bumps. More anti-squat will have more support (side to side) and be better on rough tracks with big

jumps.

Ride Height:

Measuring from a flat surface to the bottom face of the chassis, adjust the front of the chassis with 39mm of ride height and 42mm in the rear. We

have found the 8IGHT-T 2.0 handles best when the front ride height is 2mm to 3mm lower or at least level than the rear of the truck. To measure your

ride height properly we recommend using the Losi Ride Height Gauge (LOSA99173).