9

1

2

3

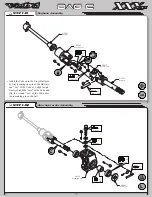

Diff Nut

Diff Spring

A2908

Outdrive, Male

A3038

Diff Ring Shim

(Bronze)

A3039

Diff Ring

(Chrome)

A3039

Diff Gear, 51T

A3036

Diff Balls, Carbide

A6951

A2911

4

5

Foam Diff Seal

A3078

A3078

Diff Screw

A3018

Thrust Bearing

A3038

Outdrive, Female

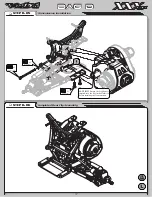

Idler Shaft

A2937

Top Shaft

A9930

Motor Plate

A3041

Gearbox, Left

A3033

A3033

Gearbox, Right

A3079

Idler Gear

A3034

2-56 x 5/8"

Cap Head Screw

Apply a small amount of Clear Diff Grease to

both Diff Outdrives and the Diff Ring Shims

before installing the Diff Rings.

Apply enough Clear Diff Grease to the top side

of the Diff Rings, or to both sides of recessed

Ball section in the Diff Gear (after Diff Balls

are installed) to cover the Diff Balls when the

Diff is assembled.

Assemble the Diff and tighten until some resis-

tance is felt, see the Final Checklist and Setup

Guide for

fi

nal Diff adjustment procedures.

•

•

•

Small Center Hole

Large Center Hole

The Diff Ring Shims are optional. If you choose

not to use them (See Setup Guide), you must

install the smaller Diff Shims on the outside of

the Diff before installing the Diff into the Gear-

box case.

•

The Diff Ring Shims are optional. If you choose

not to use them (See Setup Guide), you must

install the smaller Diff Shims on the outside of

the Diff before installing the Diff into the Gear-

box case.

•

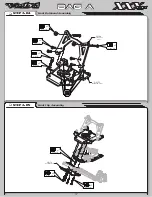

BAG D

BAG D

Differential Assembly

STEP D-01

Transmission Assembly

STEP D-02

5mm x 8mm

x2

1/8” x 3/8”

x2

3/16” x .140”

x1

1/2” x 3/4”

x2

3/16” x 3/8”

x2

4-40 x 1-1/8”

x2

4-40 x 3/8”

x1

1

2

3

4

5