22

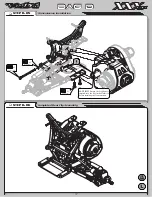

Outboard Camber Location:

Running the camber link in the inside position (A) on the hub will generate more rotation entering a turn, but

decrease steering on exit. Running the camber link in the furthest outer position (C) on the hub will generate more stability entering a turn

and increase steering on exit.

Outboard Camber Vertical Adjustment:

New to the XXX-CR is the vertical mounted ball stud on the hub. Washers are often used under the

outer ball stud to determine the height of the ball stud. Raising the height of the ball stud increases camber gain while lowering the height of

the ball stud decreases camber gain. Testing has shown that running the inboard rear camber ball stud in a higher location (less angle relative

to arm = less camber gain) on high traction surfaces offers improved stability with decreased rear grip. Also, on low traction surfaces, running

the inboard rear camber ball stud in a lower location (more angle relative to arm = more camber gain) will increase rear grip.

Toe-In:

Having the same de

fi

nition as for the front end, the toe-in can be adjusted on the XXX-CR with the rear hubs. The stock toe-in is

3 degrees of inboard per side and 0 degrees in the hub. Increasing rear toe-in will increase forward traction and initial steering, but reduce

straightaway speed. Decreasing rear toe-in will decrease forward traction and “free-up” the car. Less toe-in can be used for stock racing to

gain top speed.

Anti/Pro-Squat:

In the stock con

fi

guration, the XXX-CR has 2 degrees of anti-squat. Increasing anti-squat is generated by raising the front

of the pivot block, relative to the rear of the pivot. This will increase initial steering and forward traction. You can increase anti-squat in 1

degree increments by using two .030” washers between the front of the pivot plate and pivot block. Pro-squat is generated by raising the rear

of the pivot relative to the front. This will decrease forward traction and initial steering, but provide more on-power steering on high traction

tracks. Pro-squat will also help the car from pulling wheelies on high bite surfaces. Also available is an aftermarket part that is a 0 degree rear

pivot block (LOSA2112), if pro-squat is desired it is best to start with this option.

Variable Length Arm and Carrier:

Like the front of the XXX-CR, the rear end also has variable length arms and carriers. The stock setting

is in the short arm location which offers the best balance for most tracks. Moving the hinge pin to the outer location of the arm and hub will

give a long arm setting which is suitable for tracks where less rear traction is needed. This can be used on high bite tracks to help settle the

car down from the rear end. For the long rear arm length, the spring rate will need to be increased to a red rear spring (2.6lb-LOSA5152), The

oil will also need to be increased from the stock setting of 27.5wt. to 32.5wt. oil to keep the same static dampening.

Tuning the Chassis of the

XXX-CR

Slipper Adjustment:

This should be done after the diff is properly adjusted. If you have just

fi

nished adjusting the differential, loosen the

slipper adjustment nut four full turns. This will be a good starting point for your slipper settings.

Ride Height:

This is the height of the chassis in relation to the surface of the track. It is an adjustment that affects the way your car jumps,

turns, and goes through bumps. To check the ride height, drop one end (front or rear) of the car from about a 5-6 inch height onto a

fl

at sur-

face. Once the car settles into a position, check the height of that end of the car in relationship to the surface. To raise the ride height, lower

the shock adjuster nuts on the shock evenly on the end (front or rear) of the car that you are working on. To lower the ride height, raise the

shock adjuster nuts. Both left and right nuts should be adjusted evenly.

You should start with the rear ride height where the car comes to a rest at a height where the dog bones are slightly below level with the

surface. The front ride height should be set so that the bottom of the chassis is level with the surface. Occasionally, you may wan to raise the

front ride height to get a little quicker steering reaction but be careful as this can also make the car easily

fl

ip over. Every driver likes a little

different feel so you should try small ride height adjustments to obtain the feel you like. We have found that ride height is really a minor

adjustment. This should be one of the last adjustments after everything else has been dialed in (tuned). Do not use ride height adjustment as

a substitute for a change in spring rate. If your car needs a softer or

fi

rmer spring, change the spring. Do not think that simply moving the

shock nuts will change the stiffness of the spring; it will not!

Battery Position:

This is a critical adjustment that is often overlooked but can be very useful. Start by running the battery spaced forward

(kit setup). Moving the battery back can improve rear traction on slippery surfaces. Moving the battery back too far can cause the rear end to

swing through turns on some tracks. This is a result of having the weight too far back. The XXX-CR comes equipped with one foam battery

spacer. This can be cut in half (lengthwise and carefully) to split the difference when adjusting the battery position, hence offering a middle

position when either extreme is inadequate.

Camber Rise Relationship:

The XXX-CR setup out of the box comes with less front camber gain than the rear camber gain. The reason for

this is that less front camber lets the front end drive

fl

atter and makes the car more stable. By having more camber gain in the rear gives the

car more rear traction and helps the rear tires accelerate through the bumps and ruts.

Steering:

The XXX-CR has incorporated a new Ackermann steering link that provides reverse Ackermann. The reverse Ackermann gives the

car a smoother steering response into the turn with more steering on corner exit and helps keep the car consistent during changing track condi-

tions. The new Ackermann link will help the front of the car stay

fl

atter through the turn and also help the front end from getting “grabby” on

rutted/bumpy tracks. By adding a .030” washer to the ball studs on the link will result in less reverse Ackermann and will give the car more

steering into the turn but less steering on corner exit.

Front Wing/Rear Wing Setup:

Another tuning option included with the XXX-CR is done with down force with a new front and rear wing

set. Included in the kit is a front wing that when installed will give the car more down force onto the front end that will result in more overall

steering. This can be used on high traction tracks where a greater amount of steering is needed. On the rear of the car is a new wing that is

½” wider than the existing rear wings that have proceeded in the previous XXX kits. The larger rear wing adds more stability needed with

SETUP GUIDE

SETUP GUIDE