157

156

153

154

152

155

119

151

152

119

Ba

Ba

Ba

Ba

Bag H

g H

g H

g H

g H

34

Figure H-2

Figure H-1

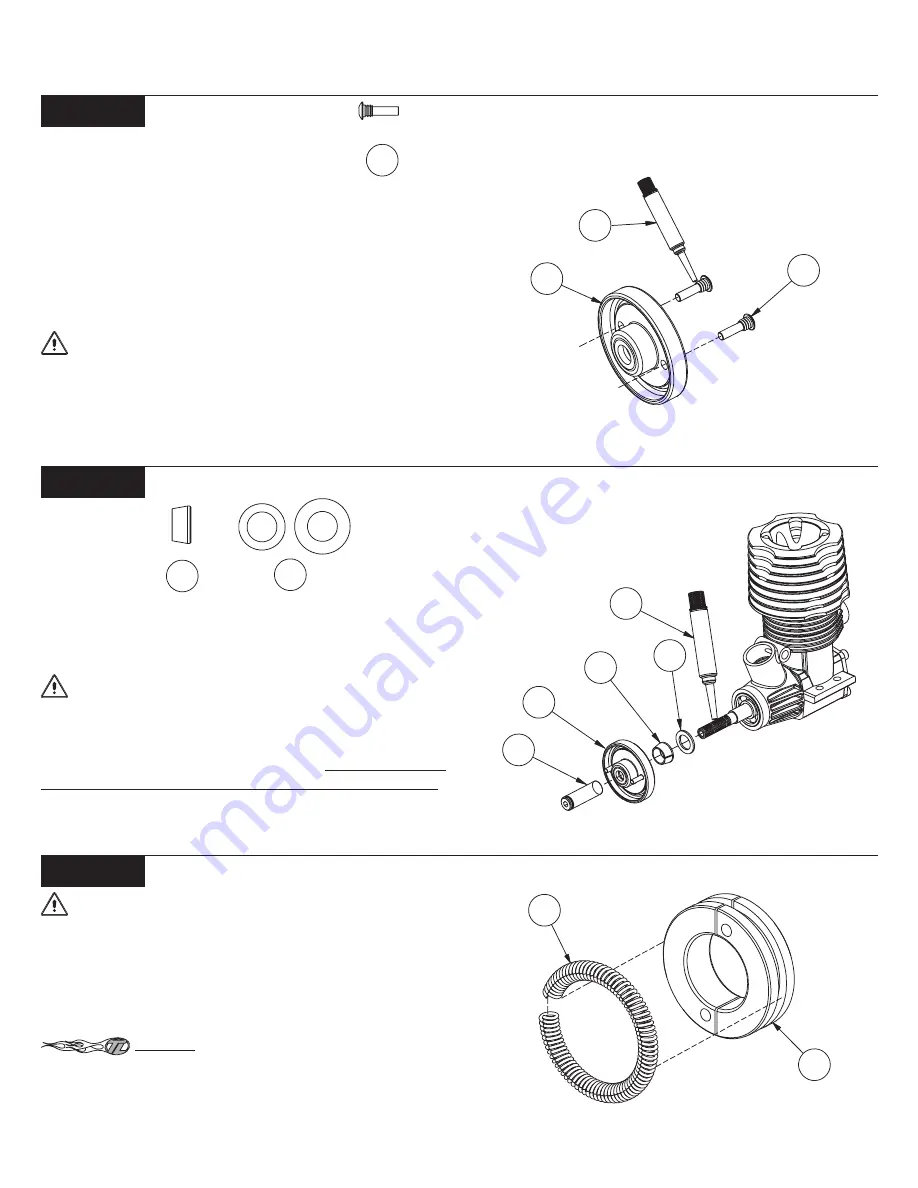

1. Slide the correct size Flywheel Shim, for your engine, (153)

over the crankshaft, and against the front Bearing on the engine.

Slide the Flywheel Collet (154), large side first, over the crankshaft

and next to the Shim.

IMPORTANT NOTE: The Clutch Nut should be very tight.

Hold the Flywheel with a rag in order to get a good grip while tighten-

ing the Clutch Nut. There are special tools available for inserting in

the head of the engine to keep it from turning over while tightening

the Clutch Nut. Other than these special tools, nothing should ever

be inserted in the head of the engine to keep it from turning over!

2. Slide the Flywheel (152), Pins out, over the crankshaft. The

Flywheel should be seated over the Collet. Thread the Clutch Nut

(155) onto the crankshaft and tighten it using a 3/32" Allen wrench.

Step H-1

Step H-1

Step H-1

Step H-1

Step H-1

Step H-2

Step H-2

Step H-2

Step H-2

Step H-2

151

Clutch Pin Install:

154

Flywheel Install:

153

IMPORTANT NOTE: The Clutch Shoes may come in a single

piece, and must be completely separated to operate properly. Bend

the Shoes along the cut and pull the two halves apart.

1. Hook the two ends of the Clutch Spring (156) together to form

a loop as shown. Stretch the looped Spring over the two Clutch Shoes

(157) so that the Clutch Shoes form a circle. Make sure that the holes

in the Clutch Shoes are on opposite sides of the circle as shown.

LIGHTLY sand the outer surface of the clutch shoes

can improve their performance. Sand the shoes using a 400 grit, or

finer sandpaper. Sand the shoe surface lengthwise, not across the

shoe sideways. DO NOT use a sanding block, or lay the sandpaper

on a flat surface. Too much sanding may cause flat spots to develop

on the shoes.

Step H-3

Step H-3

Step H-3

Step H-3

Step H-3

Figure H-3

1. Remove any hardware that came installed on the crankshaft of

your engine. This includes all nuts, washers, and prop hubs.

*NOTE: If your engine did not come with a glow plug you will

need to purchase one. Use a glow plug wrench, or a 5/16" nut driver

to install the glow plug into the head of the engine. Most glow plugs

come with a brass washer, and should be placed between the head

of the engine and glow plug. However the engine Manufacturer

instructions should be followed.

IMPORTANT NOTE: A small amount of Thread-Lock compound

must be used on the threads of the Clutch Pins.

2. Place a drop of Thread Lock (119) on the threads of each

Clutch Pin (151).

3. Thread a Clutch Pin into each of the small holes in the Fly-

wheel (152) and tighten with a .050" Allen Wrench, as shown.

Clutch Shoe Assembly:

Summary of Contents for XXX-NT AD2

Page 65: ......