i

TOOLS REQUIRED

Team Losi has supplied all necessary allen wrenches and a special assembly wrench that is needed for assembly and turnbuckle adjustments.

The following common tools will also be required: Needle-nose pliers, regular pliers, medium grit sandpapper, hobby knife, scissors, and body

cutting/trimming tools. A soldering iron may be necessary for electrical installation. 3/16", 1/4", and 11/32" nut drivers are optional.

RADIO/ELECTRICAL

A suggested radio layout is provided in this manual. Your high-performance R/C center should be consulted regarding specific questions

pertaining to radio/electrical equipment.

HARDWARE IDENTIFICATION

When in question, use the hardware identification guide in each step. For screws, the prefix number designates the screw size and number of

threads per inch (i.e. 4-40 is #4 screw with 40 threads per inch). The second number or fraction designates the length of the screw. For cap head

and button head screws, this number refers to the length of the threaded portion of the screw. For flat head screws, this number refers to the

overall length of the screw. Bearings and bushings are referenced by the inside diameter

x

outside diameter. Shafts and pins are referred to by

diameter

x

length. Washers are described by inside diameter or the screw size that will pass through the inside diameter. E-clips are sized by the

shaft diameter that they attach to.

MOTORS AND GEARING

The XXX-S includes an 90-tooth, 48-pitch spur gear. The internal drive ratio of the XXX-S is 1.83. The pinion gear that is used will determine

the final drive ratio. To calculate the final drive ratio, first divide the spur gear size by the pinion gear size. For example, if you are using a 20-tooth

pinion gear, you would divide 90 (spur gear size) by 20 (pinion gear size). 90/20 = 4.50. This tells you that 4.50 is the external drive ratio. Next,

multiply the internal drive ratio (1.83) by the external drive ratio (in this case 4.50). 1.83 x 4.50 = 8.235. This means that by using a 20-tooth pinion

gear with the standard 90-tooth spur gear, the final drive ratio is 8.235:1.

Consult your high-performance shop for recommendations to suit your racing style and class. The chart below lists some of the more

common motor types and recommended initial gearing for that motor. Ratios can be adjusted depending on the various track layouts, tire sizes,

and battery types.

RECOMMENDED INITIAL GEARING FOR COMMON MOTORS

TYPE OF MOTOR

PINION

SPUR

24º Stock

26

90

8-Turn Modified

16

90

9-Turn Modified

17

90

10-Turn Modified

18

90

11-Turn Modified

19

90

12-Turn Modified

20

90

13-Turn Modified

21

90

14-Turn Modified

21

90

15-Turn Modified

22

90

TABLE OF CONTENTS

1. INTRODUCTION ................................................................................ i

Completed Kit Dimensions .............................................................. i

Notes & Symbols .............................................................................. i

Kit Manual Organization .................................................................. i

Important Safety Notes .................................................................... i

Tools Required ................................................................................. ii

Radio/Electrical ................................................................................ ii

Hardware Identification .................................................................. ii

Recommended Gearing ................................................................... ii

2. BAG A ............................................................................................... 1-3

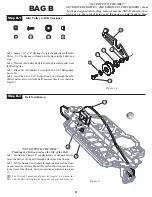

3. BAG B ............................................................................................... 4-7

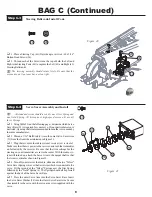

4. BAG C ........................................................................................... 8-11

5. BAG D ........................................................................................ 12-16

6. BAG E ......................................................................................... 17-21

7. BAG F ......................................................................................... 22-24

8. BAG G ................................................................................................ 25

9. BAG H ........................................................................................ 26-30

10. Checklist Before Your First Run ................................................. 31

11. Tips From the Team .................................................................. 31-33

12. Spare Parts List ........................................................................ 34-36

13. Blank Set-up Sheet .......................................................................... 37

Team Losi is continually changing and improving designs; therefore, the actual part may appear slightly different than the illustrated part. Illustrations of parts and

assemblies may be slightly distorted to enhance pertinent details.

i