FRONT:

One of the first things I adjust is the front camber link. The standard MF link is 2-B with 1 washer. If the

truck seems to push (not enough steering), move the link to the outer hole, #3. This will give the truck more

steering and make the truck respond quicker. If the truck has too much steering, remove the washer in the

standard (2) hole leaving no washers. This will allow the front end to lean more into the turn and make the

front plow (less steering) through the turn. On slippery tracks I prefer to run a shorter link, 3-B because it

gives the truck more traction throughout the turn increasing steering both entering and exiting.

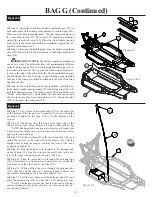

Shock Location:

The XXXT has four possible shock mounting locations. Standard position is #2. Mov-

ing to #1 will give the truck more low speed steering and quicker response to steering. Moving out to 3 or 4

will give more high speed steering. On fast wide-open tracks I generally move the shock to the outer hole. On

low speed tight tracks I move the shock to the inner location, #1.

REAR:

Camber link:

Generally a shorter camber link will have more side traction and less forward traction. But,

on slippery track conditions, I will shorten my camber link to 3-A to increase the rear traction. A shorter

camber link increases traction because it allows the truck's rear suspension to "square up" (return to center)

quicker. On high bite tracks, a longer rear camber link will make the truck's steering smoother and easier to

drive.

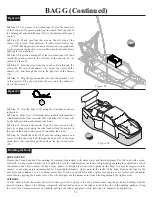

Shock Location:

Moving the upper mounting location inward will soften the rear suspension giving the

truck more low speed traction. Moving the mounting location outward, gives the truck more high-speed

traction. But, moving outward will decrease the truck's ability to "carve" the turn smoothly. On high bite tracks

I move the mounting location inward to allow the truck to rotate through the turn smoothly. On low bite

conditions, move the mounting location outward to give more overall traction.

Weight Balance:

The XXXT allows the adjustment of the battery both forward and back. Moving the

battery forward will give the truck less off throttle steering and more on throttle steering. Also, moving the

battery forward on high bite tracks helps eliminate the truck's tendency to pull wheelies due to too much

forward traction. On a loose track, move the battery back to get more forward traction exiting turns.

Anti-Squat:

My stock set up is 2 degrees. Adding the anti-squat shims under the front of the block will

result in 4 degrees. This gives less side-bite allowing the rear of the truck to rotate easier and more steering

from the rear. It also gives the truck more forward traction and air off of big jumps. Adding the shims under

the rear of the block results in 0 degrees. This gives more side-bite but less forward traction and air off of big

jumps.

I hope these tips will give you a good basis for adjusting your truck to your personal driving style. Keep in

mind every track is different and require minor adjustments to your truck. The above tuning tips should be

enough to put your truck in the winner's circle.

Thank you and good luck.

Matt Francis

Additional Tuning Tips From Matt

Summary of Contents for XXX-T Matt Francis Edition

Page 2: ......