BAG A (Continued)

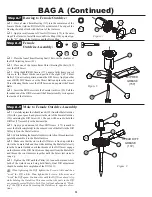

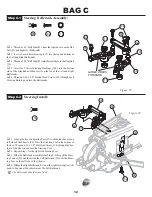

Step A-14

q

1. Insert a 5mm x 8mm Bearing (117) into the center of the 42T Diff

Pulley (42).

q

2. Press a 3/32" Diff Ball (82) into each of the small holes in the

Diff Pulley as indicated in Figure 14.

Diff Pulley:

117

82

Figure 14

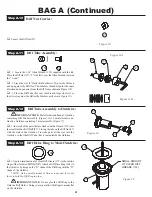

Step A-15

q

1. Apply a moderate coat (continuous bead, same as step A-9) of

Clear Diff Grease (172) to the exposed side of the Diff Ring (108) that

is already attached to the Male Outdrive (87).

q

2. Carefully place the Diff Pulley (42) over the post on the

Outdrive so that the Diff Balls (82) and Diff Pulley rest against the

Greased Diff Ring. Leave the assembly with the 1/16" Allen Wrench

(125) standing as shown in Figure 15.

5

FIGGIGUREFASDF

82

42

117

Diff Pulley to Diff Tube:

108

42

82

CLEAR DIFF

GREASE (172)

87

Figure 15