AX48-120 Flange Facing Machine

10

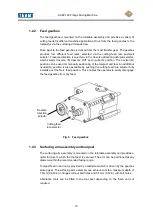

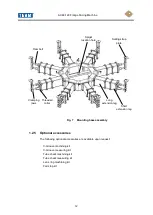

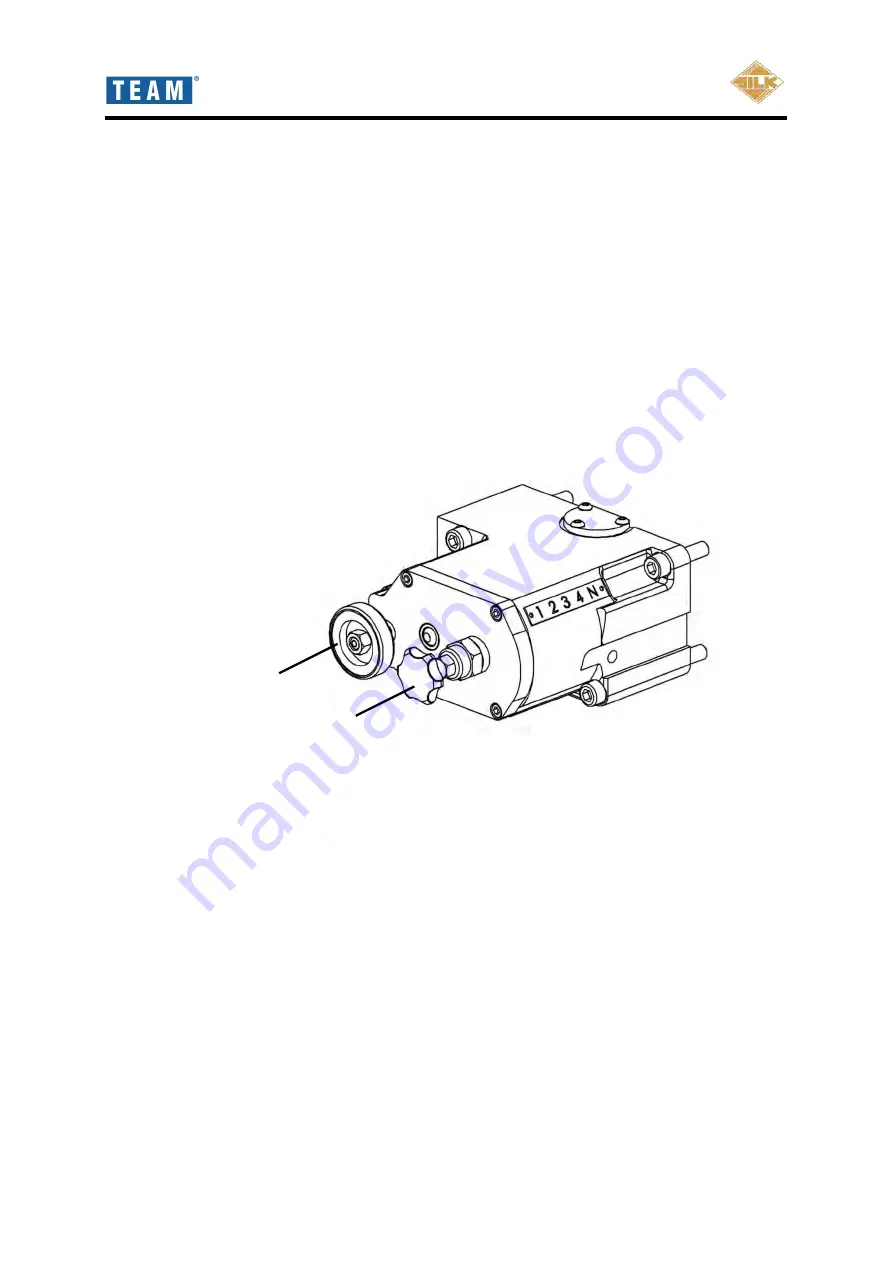

1.2.2 Feed gearbox

The feed gearbox is mounted on the turntable assembly and provides a variety of

cutting feeds for different machine applications. Drive from the feed gearbox to the

toolpost is via the surfacing arm leadscrew.

Drive input to the feed gearbox is derived from the mast transfer gear. The gearbox

provides four different feed rates, selected via the cutting feed rate push/pull

selector. Traverse direction is selected via the traverse direction push/pull selector,

which selects traverse IN, traverse OUT and neutral N position. The neutral (N)

position can be used for manually positioning of the toolpost and tool. An additional

neutral (N) position is also available by pushing the cutting feed rate selector fully

inwards past the No.4 feed position. This enables the operator to easily disengage

the feed gearbox from any feed.

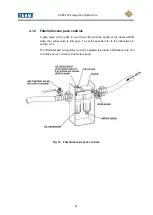

Fig. 5 Feed gearbox

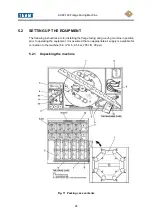

1.2.3 Surfacing arm assembly and toolpost

The surfacing arm assembly is mounted on the turntable assembly and provides a

rigid structure to which the tool post is secured. The arm can be positioned at any

diameter within the recommended facing range.

Toolpost feed in and out is provided by a leadscrew which is driven by the gearbox

pickup gear. The surfacing arm assembly can achieve cuts to a maximum depth of

1.0mm (0.040in) in flanges without bolt holes and 0.5mm (0.02in.) with bolt holes.

Alternative tools can be fitted to the tool post depending on the finish and cut

required.

Traverse

direction

selector

Cutting feed

rate selector

Summary of Contents for SILK AX48-120

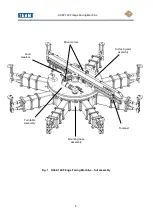

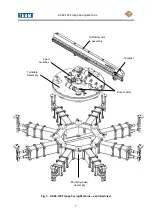

Page 51: ...AX48 120 Flange Facing Machine 50 Fig 26 Mast and turntable assembly sheet 1 ...

Page 52: ...AX48 120 Flange Facing Machine 51 Fig 27 Mast and turntable assembly sheet 2 ...

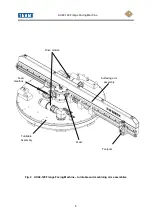

Page 55: ...AX48 120 Flange Facing Machine 54 28 Surfacing arm assembly sheet 1 ...

Page 56: ...AX48 120 Flange Facing Machine 55 Fig 29 Surfacing arm assembly sheet 2 ...

Page 59: ...AX48 120 Flange Facing Machine 58 Fig 30 Gearbox assembly ...

Page 62: ...AX48 120 Flange Facing Machine 61 Fig 31 Base assembly ...

Page 64: ...AX48 120 Flange Facing Machine 63 Fig 32 Toolpost assembly ...

Page 66: ...AX48 120 Flange Facing Machine 65 Fig 33 Base centraliser ...

Page 68: ...AX48 120 Flange Facing Machine 67 Fig 34 Counter balance ...

Page 71: ...AX48 120 Flange Facing Machine 70 TYPES OF TOOL BIT FOR GENERAL PURPOSE AND FINE FINISH ...

Page 72: ...AX48 120 Flange Facing Machine 71 TOOLS FOR V GROOVE PLUNGE MACHINING ...

Page 76: ...AX48 120 Flange Facing Machine 75 APPENDIX C V GROOVE MEASUREMENT ...

Page 77: ...AX48 120 Flange Facing Machine 76 ...

Page 78: ...AX48 120 Flange Facing Machine 77 APPENDIX D AIR MOTOR MANUFACTURERS INFORMATION ...

Page 79: ...AX48 120 Flange Facing Machine 78 ...

Page 80: ...AX48 120 Flange Facing Machine 79 ...

Page 81: ...AX48 120 Flange Facing Machine 80 ...

Page 82: ...AX48 120 Flange Facing Machine 81 ...

Page 83: ...AX48 120 Flange Facing Machine 82 ...