AX48-120 Flange Facing Machine

29

DO NOT LIFT THE BASE USING THE BAR IN THE CENTRE OF THE UNIT. THE

BAR IS FITTED TO LOCATE THE MACHINE CENTRE SPIGOT AND IS NOT

INTENDED TO TAKE THE WEIGHT OF THE BASE ASSEMBLY. ALWAYS USE

THE DEDICATED LIFTING POINTS.

If the machine is to be used on a vertical flange then follow the lifting instructions in

section 5.2.7.

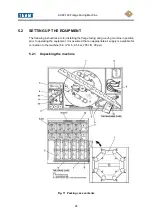

8. When the base assembly is correctly positioned within the bore, secure in the

bore (working on opposite pairs of jaws – using the upper jaws) by tightening the

ram bolts equally to maintain position.

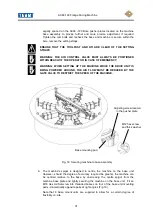

5.2.3 Centralising the base within the bore

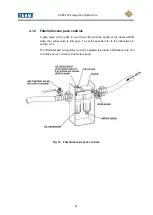

1. Position the clocking tower into spigot hole in the centre of the base unit (Fig. 15)

and slide the clocking bar into the pivoted bracket. Adjust the position of the

clocking arm to suit the flange diameter and clamp in position. Fit the spike to

the outer end of the bar and secure with the socket head screw.

2. Using the spike select the datum diameter (i.e. raised face, 'V' groove or bolt

holes) and rotate the clocking arm. Check the spike follows the datum and adjust

if necessary. To adjust the base, tighten and slacken opposite sets of ram bolts -

upper jaws (similar to a four jaw chuck operation) securing the unit progressively

in the flange until the desired accuracy has been achieved. It is possible to

achieve concentricity within 0.25mm with care.

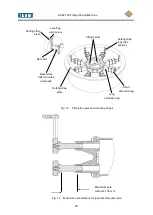

3. Tighten up all eight lower jaw units to ensure the base is secure in the bore.

Recheck the base is still centred.

4. Remove the clocking tower and arm.

During centralising ensure that all the setting straps are fitted. When centralised,

the base should be tight enough within the bore to support its own weight and that

of the turntable assembly.

NEVER SLACKEN A RAMBOLT UNLESS ALL SETTING STRAPS ARE FITTED.

Summary of Contents for SILK AX48-120

Page 51: ...AX48 120 Flange Facing Machine 50 Fig 26 Mast and turntable assembly sheet 1 ...

Page 52: ...AX48 120 Flange Facing Machine 51 Fig 27 Mast and turntable assembly sheet 2 ...

Page 55: ...AX48 120 Flange Facing Machine 54 28 Surfacing arm assembly sheet 1 ...

Page 56: ...AX48 120 Flange Facing Machine 55 Fig 29 Surfacing arm assembly sheet 2 ...

Page 59: ...AX48 120 Flange Facing Machine 58 Fig 30 Gearbox assembly ...

Page 62: ...AX48 120 Flange Facing Machine 61 Fig 31 Base assembly ...

Page 64: ...AX48 120 Flange Facing Machine 63 Fig 32 Toolpost assembly ...

Page 66: ...AX48 120 Flange Facing Machine 65 Fig 33 Base centraliser ...

Page 68: ...AX48 120 Flange Facing Machine 67 Fig 34 Counter balance ...

Page 71: ...AX48 120 Flange Facing Machine 70 TYPES OF TOOL BIT FOR GENERAL PURPOSE AND FINE FINISH ...

Page 72: ...AX48 120 Flange Facing Machine 71 TOOLS FOR V GROOVE PLUNGE MACHINING ...

Page 76: ...AX48 120 Flange Facing Machine 75 APPENDIX C V GROOVE MEASUREMENT ...

Page 77: ...AX48 120 Flange Facing Machine 76 ...

Page 78: ...AX48 120 Flange Facing Machine 77 APPENDIX D AIR MOTOR MANUFACTURERS INFORMATION ...

Page 79: ...AX48 120 Flange Facing Machine 78 ...

Page 80: ...AX48 120 Flange Facing Machine 79 ...

Page 81: ...AX48 120 Flange Facing Machine 80 ...

Page 82: ...AX48 120 Flange Facing Machine 81 ...

Page 83: ...AX48 120 Flange Facing Machine 82 ...