AX48-120 Flange Facing Machine

3

CONTENTS

TECHNICAL DESCRIPTION ........................................................................... 8

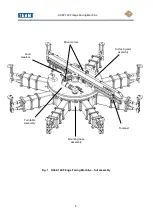

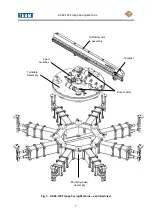

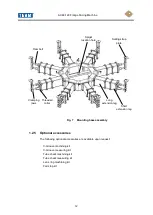

Turntable assembly ............................................................................... 8

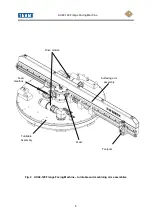

Surfacing arm assembly and toolpost .................................................10

Mounting base assembly ....................................................................11

Optional accessories ...........................................................................12

SAFETY INFORMATION ..............................................................................16

CONTROLS AND BASIC OPERATION .......................................................19

Location and function of the controls.............................................................19

Machine controls .................................................................................19

Filter/lubricator pack controls ..............................................................21

Unpacking the machine .......................................................................24

Mounting base installation ...................................................................26

Centralising the base within the bore ..................................................29

Machine installation .............................................................................30

Toolpost overrun and gearbox protection device ................................32

Installing and machine balancing - (vertical flange) ............................33

Setting up the tool - facing and grooving ............................................36

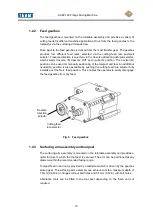

Connection to Air Supply .....................................................................37

Starting the machine - Facing and Grooving ......................................38

MAINTENANCE INSTRUCTIONS ................................................................42

Removal of gearbox ............................................................................44

Replacement of shear pins .................................................................45

Summary of Contents for SILK AX48-120

Page 51: ...AX48 120 Flange Facing Machine 50 Fig 26 Mast and turntable assembly sheet 1 ...

Page 52: ...AX48 120 Flange Facing Machine 51 Fig 27 Mast and turntable assembly sheet 2 ...

Page 55: ...AX48 120 Flange Facing Machine 54 28 Surfacing arm assembly sheet 1 ...

Page 56: ...AX48 120 Flange Facing Machine 55 Fig 29 Surfacing arm assembly sheet 2 ...

Page 59: ...AX48 120 Flange Facing Machine 58 Fig 30 Gearbox assembly ...

Page 62: ...AX48 120 Flange Facing Machine 61 Fig 31 Base assembly ...

Page 64: ...AX48 120 Flange Facing Machine 63 Fig 32 Toolpost assembly ...

Page 66: ...AX48 120 Flange Facing Machine 65 Fig 33 Base centraliser ...

Page 68: ...AX48 120 Flange Facing Machine 67 Fig 34 Counter balance ...

Page 71: ...AX48 120 Flange Facing Machine 70 TYPES OF TOOL BIT FOR GENERAL PURPOSE AND FINE FINISH ...

Page 72: ...AX48 120 Flange Facing Machine 71 TOOLS FOR V GROOVE PLUNGE MACHINING ...

Page 76: ...AX48 120 Flange Facing Machine 75 APPENDIX C V GROOVE MEASUREMENT ...

Page 77: ...AX48 120 Flange Facing Machine 76 ...

Page 78: ...AX48 120 Flange Facing Machine 77 APPENDIX D AIR MOTOR MANUFACTURERS INFORMATION ...

Page 79: ...AX48 120 Flange Facing Machine 78 ...

Page 80: ...AX48 120 Flange Facing Machine 79 ...

Page 81: ...AX48 120 Flange Facing Machine 80 ...

Page 82: ...AX48 120 Flange Facing Machine 81 ...

Page 83: ...AX48 120 Flange Facing Machine 82 ...