AX48-120 Flange Facing Machine

30

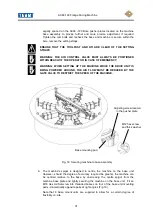

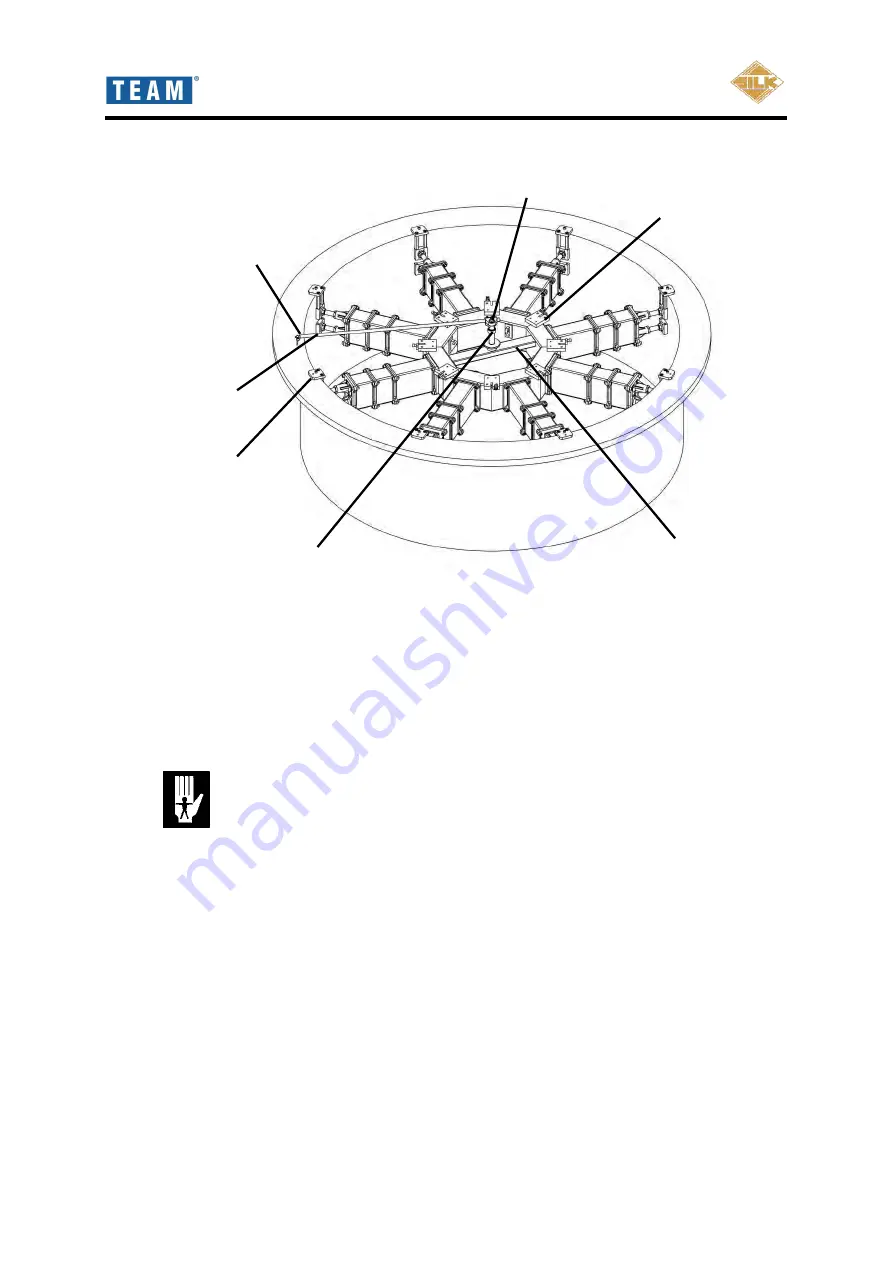

Fig. 15 Base centraliser fitted to spigot hole

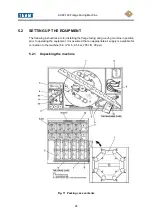

5.2.4 Machine installation

1. Determine if the fall-stop kit is needed (refer to Appendix E).

WARNING: FAILURE TO FIT THE FALL-STOP KIT MAY RESULT IN SERIOUS

INJURY OR DAMAGE TO THE MACHINE.

2. Fit the location spigot to the bottom of the turntable base.

3. Ensure that the toolpost is fully retracted and the tool has been removed.

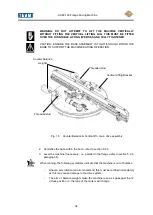

4. Carefully position the machine onto the base and locate the centre spigot into

the centering hole. Aligning the slots in the machine's mounting brackets with the

base mounting pad slots. Slide the mounting studs upwards to locate into the

slots and secure the machine with M12 hex. nuts and thick washers (Fig.16).

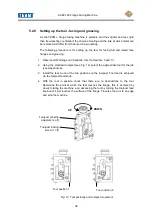

5. Although the machine has been designed to be located in the flange bore

without the need for levelling it may be necessary, when machining flanges with

uneven variations in surface height, to check the machine is parallel to the

flange.

To check, attach and secure a DTI to the toolpost, connect the machine to the

air supply and set the gearbox traverse selector to neutral (N). Open the air

control valve and slowly move the surfacing arm around the flange. Check the

DTI for variations and adjust if necessary by tightening the M12 Hex Hd

Setscrews in the centre of each setting strap plate against the flange face and

pulling the base up the bore (coarse setting). 8 Off - M16 Hex Hd Setscrews are

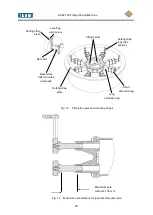

Central tie

bar

Clocking arm

Spike

Clocking tower

Pivoted

bracket

Setting strap plate

Adjusting

Screw

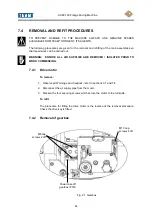

Summary of Contents for SILK AX48-120

Page 51: ...AX48 120 Flange Facing Machine 50 Fig 26 Mast and turntable assembly sheet 1 ...

Page 52: ...AX48 120 Flange Facing Machine 51 Fig 27 Mast and turntable assembly sheet 2 ...

Page 55: ...AX48 120 Flange Facing Machine 54 28 Surfacing arm assembly sheet 1 ...

Page 56: ...AX48 120 Flange Facing Machine 55 Fig 29 Surfacing arm assembly sheet 2 ...

Page 59: ...AX48 120 Flange Facing Machine 58 Fig 30 Gearbox assembly ...

Page 62: ...AX48 120 Flange Facing Machine 61 Fig 31 Base assembly ...

Page 64: ...AX48 120 Flange Facing Machine 63 Fig 32 Toolpost assembly ...

Page 66: ...AX48 120 Flange Facing Machine 65 Fig 33 Base centraliser ...

Page 68: ...AX48 120 Flange Facing Machine 67 Fig 34 Counter balance ...

Page 71: ...AX48 120 Flange Facing Machine 70 TYPES OF TOOL BIT FOR GENERAL PURPOSE AND FINE FINISH ...

Page 72: ...AX48 120 Flange Facing Machine 71 TOOLS FOR V GROOVE PLUNGE MACHINING ...

Page 76: ...AX48 120 Flange Facing Machine 75 APPENDIX C V GROOVE MEASUREMENT ...

Page 77: ...AX48 120 Flange Facing Machine 76 ...

Page 78: ...AX48 120 Flange Facing Machine 77 APPENDIX D AIR MOTOR MANUFACTURERS INFORMATION ...

Page 79: ...AX48 120 Flange Facing Machine 78 ...

Page 80: ...AX48 120 Flange Facing Machine 79 ...

Page 81: ...AX48 120 Flange Facing Machine 80 ...

Page 82: ...AX48 120 Flange Facing Machine 81 ...

Page 83: ...AX48 120 Flange Facing Machine 82 ...