AX48-120 Flange Facing Machine

32

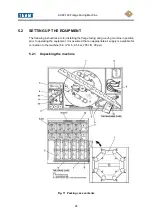

7. The machine can then be accurately centred by turning the adjusting screw on

each of the mounting pads, allowing the machine to be pushed into position.

Clock the 'V' groove etc. and when accurately set, secure the machine and

check again.

WARNING: DO NOT REMOVE THE SETTING PLATES UNTIL THE MACHINE IS

SECURE AND ALL ADJUSTMENTS ARE COMPLETE.

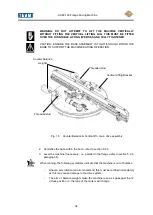

5.2.5 Setting up the tool

As the TEAM

®

flange facing machine is portable and thus lighter and less rigid

than its workshop counterpart, the choice of tooling and the rate at which metal can

be removed will differ from that used in a workshop.

When the tool has been selected it can be installed in the toolpost and secured by

the clamp. Tool feed is achieved via the toolpost feed knob which is fitted with a

graduated scale divided into metric and imperial increments.

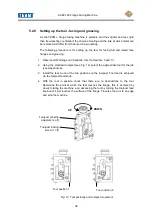

5.2.6 Toolpost overrun and gearbox protection device

The Toolpost Overrun and Gearbox Protection Device are designed to stop the

toolpost leadscrew nut jamming against a fixed surfacing arm end plate and thus

damaging the feed gearbox. When the feed nut comes into contact with the end

plate it will push the plate along its mounting studs. Should the operator fail to

notice his error eventually the plate will fall off.

The toolpost and machine will still operate correctly without the end plate but if it is

not replaced the cast iron dovetail slideway may be damaged. To replace the end

plate see paragraph 7.4.6 in the Maintenance section.

Summary of Contents for SILK AX48-120

Page 51: ...AX48 120 Flange Facing Machine 50 Fig 26 Mast and turntable assembly sheet 1 ...

Page 52: ...AX48 120 Flange Facing Machine 51 Fig 27 Mast and turntable assembly sheet 2 ...

Page 55: ...AX48 120 Flange Facing Machine 54 28 Surfacing arm assembly sheet 1 ...

Page 56: ...AX48 120 Flange Facing Machine 55 Fig 29 Surfacing arm assembly sheet 2 ...

Page 59: ...AX48 120 Flange Facing Machine 58 Fig 30 Gearbox assembly ...

Page 62: ...AX48 120 Flange Facing Machine 61 Fig 31 Base assembly ...

Page 64: ...AX48 120 Flange Facing Machine 63 Fig 32 Toolpost assembly ...

Page 66: ...AX48 120 Flange Facing Machine 65 Fig 33 Base centraliser ...

Page 68: ...AX48 120 Flange Facing Machine 67 Fig 34 Counter balance ...

Page 71: ...AX48 120 Flange Facing Machine 70 TYPES OF TOOL BIT FOR GENERAL PURPOSE AND FINE FINISH ...

Page 72: ...AX48 120 Flange Facing Machine 71 TOOLS FOR V GROOVE PLUNGE MACHINING ...

Page 76: ...AX48 120 Flange Facing Machine 75 APPENDIX C V GROOVE MEASUREMENT ...

Page 77: ...AX48 120 Flange Facing Machine 76 ...

Page 78: ...AX48 120 Flange Facing Machine 77 APPENDIX D AIR MOTOR MANUFACTURERS INFORMATION ...

Page 79: ...AX48 120 Flange Facing Machine 78 ...

Page 80: ...AX48 120 Flange Facing Machine 79 ...

Page 81: ...AX48 120 Flange Facing Machine 80 ...

Page 82: ...AX48 120 Flange Facing Machine 81 ...

Page 83: ...AX48 120 Flange Facing Machine 82 ...