4

Maintenance mode

Maintenance mode is an operation mode when all theft prevention

and service functions of Immobilizer are temporarily deactivated.

With Maintenance Mode on, entering the PIN code is not needed when

driving the vehicle, which is helpful when the car needs to be put for

maintenance in the service center. Still, in order to enter the Program-

ming mode, it is necessary to enter the PIN code.

When the ignition is turned on in Maintenance mode, a long audible

tone is sounded that reminds on the fact that the Immobilizer is in main-

tenance mode. The audible tone can be turned off for secrecy level

increase.

In order to activate or deactivate the Maintenance mode you need

to do the following:

1

Turn the ignition on Enter the PIN code and wait for confirmation

2 Press and release the Programming mode button 6 times (start

doing it no later than 10 seconds after PIN code entering).Please

wait for confirmation that you have successfully performed

the actions:

◊

1 audible signal and 1 sound trill mean that the Maintenance

mode is ON.

◊

2 audible signals and 1 sound trill mean that the Maintenance

mode is OFF.

3 Turn the ignition off.

Additional features

The Immobilizer has additional features improving the vehicle se-

curity level.

Comfort feature control

The Immobilizer can be programmed so that the vehicle’s windows

are closed when the vehicle’s security is Armed. Please see Integrator

files for supported vehicles.

Electro-mechanic hood locks control

The Immobilizer allows closing an accessory hood lock simultane-

ously with vehicle locking and opening the hood lock when the PIN

code has been entered.

Central locking control

If the vehicle is not equipped with the following functions:

◊

Doors locking during driving

◊

Doors unlocking upon turning the ignition off

They can be car-

ried out by the Immobilizer.

Please see Integrator for list of supported vehicles.

Глава II. Connection

Immobilizer Inputs/Outputs

Immobilizer Inputs / Outputs functionalities are described in the Im-

mobilizer port description Table. Connection pin numeration is indicated

on fig. 1. Aside from outputs with set functions Immobilizer is equipped

with two programmable outputs each of which can be assigned with

one of 20 functions (see CAN bus adapter features table). These

outputs are set for controlling an accessory hood lock. Output con-

figuration is carried out via programming (see Immobilizer hardware

functions programming (Menu 1)).

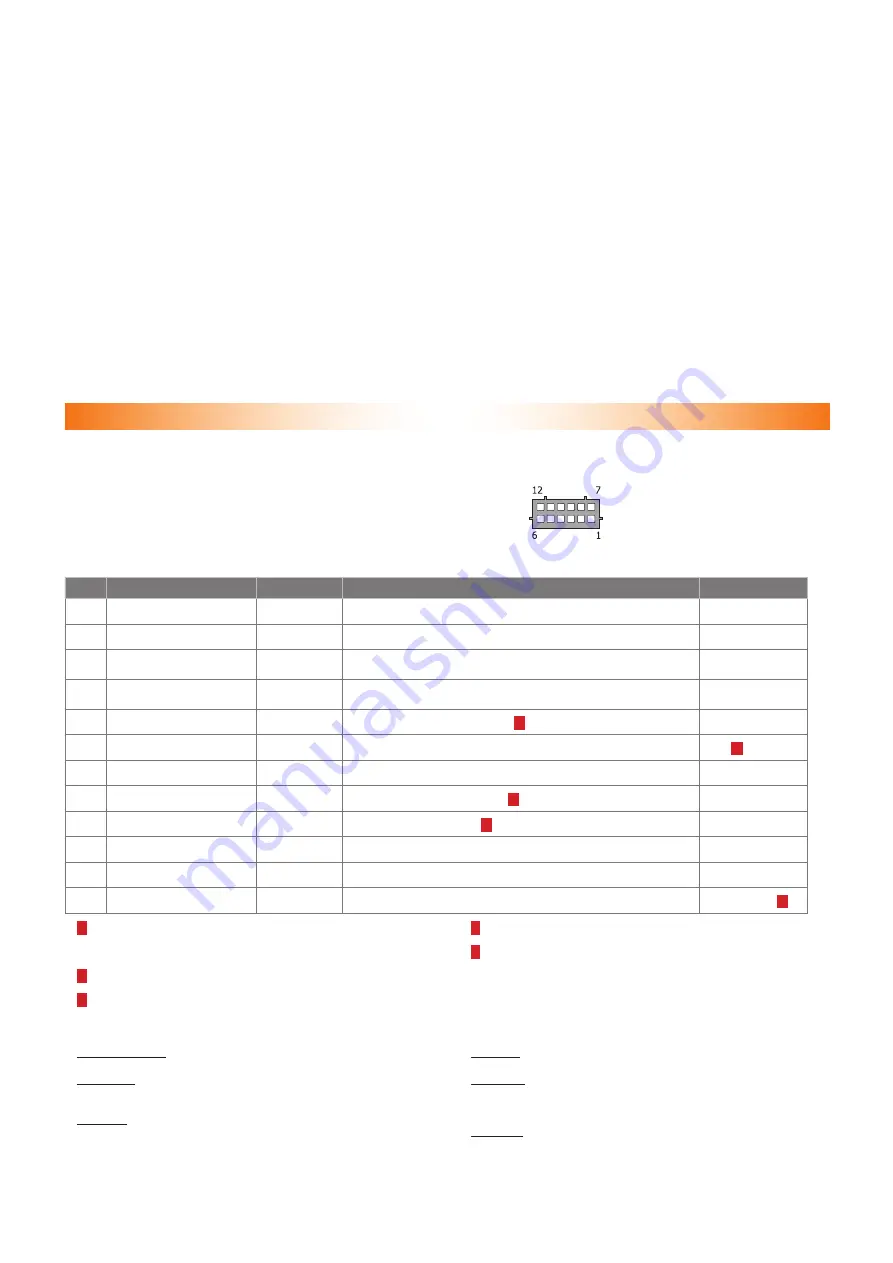

Рис. 1.

Port connector pins

enumeration from wir-

ing viewpoint

Table 1. Immobilizer port description

No.

Color

Type

Function

Current, mA

1

Brown/red

CAN

CAN-H vehicle data bus

–

2

White/black

- output

Engine locking

150

3

Gray/green

- output

Programmable negative output (Lock Impulse by default)

50

4

Gray/blue

- output

Programmable negative output (driver authentication by default)

50

5

Blue/red

+/– output

Alternate hazard lights control

1)

150

6

Black

power supply Ground

–

2)

7

Brown

CAN

CAN-L vehicle data bus

–

8

Pink/Green

+ input

Brake lights condition control

3)

1,5

9

Yellow/red

-

Communication channel

4)

–

10

Gray/yellow

+ input

Analog button/Positive button

–

11

Gray/black

- input

Reference ground/Negative button

–

12

Red

power supply

+12 В

1200(3,5)

5)

1)

– Is an output with convertible electrical polarity. Polarity is set automati-

cally upon unit interfacing with the vehicle. This output is used for al-

ternate hazard lights control in vehicles that do not support CAN bus

control.

2)

– Useful current of output No. 6 depends on connected load of the nega-

tive outputs.

3)

– Input No. 8 is to be connected only in vehicles where CAN bus does

not contain data on brake pedal position (see Integrator files).

4)

– Upon Immobilizer installation it is necessary to check the connection

in between the central unit and the relay.

5)

– Maximum useful current rate in transfer (impulse) and idle modes

is indicated. It may vary depending on demand in output No. 5.

Outputs No. 2, 3, 4 are protected from short circuit, inductive erup-

tions, overheating and maximum demand surpassing.

Immobilizer pin connectors’ description

Pins No. 1 and 7. “CAN-H and CAN-L vehicle data bus” are connected

to vehicle CAN bus (see “Integrator files”).

Pin No. 2. “Engine lock” is connected to one of relay coil con-

tacts, which is used for engine operation or ignition lock. The output

can be set for controlling a normally-open or normally-closed relay

Pin No. 3. Programmable negative output (“Lock Impulse” by default).

Pin No. 4. Programmable negative output (“Vehicle owner authentica-

tion” by default).

Pin No. 5. “Alternate hazard light control” is used for hazard light

controlling on vehicles where CAN bus control is not available. Please

see Integrator files software product for information on vehicle-specific

connection features.

Pin No. 6. “Ground” is connected to vehicle body in one of the loca-

tions determined by vehicle manufacturer for original equipment ground

connection