5-2

5. TROUBLESHOOTING

EM18-33012

5. TROUBLESHOOTING

• Replace the print head.

• Replace the print head harness.

• Replace the CPU PC board.

• Use only TOSHIBA TEC specified

media.

• Clean the print head and remove

the dust from the media.

• Use only TOSHIBA TEC specified

ribbon.

• Replace the ribbon rewind motor

or ribbon feed motor.

• Use only TOSHIBA TEC specified

ribbon.

• Refer to page 2-3 to adjust the

ribbon end sensor.

• Replace the ribbon end sonsor.

• Replace the CPU PC board.

• Set the paper properly.

• Use the paper approved by

TOSHIBA TEC.

• Re-adjust the sensor.

• Replace the feed gap sensor or

black mark sensor.

• Replace the take-up motor or CPU

PC board.

• Install the cutter mechanism

properly.

• Replace the stepping motor or

CPU PC board.

• Replace the cable.

• Replace the connector.

• Replace the connector.

• Modify the program.

• Replace IC5 (MC145407).

If the trouble is not solved, replace

the CPU PC board.

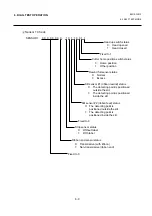

Dot missing

Blurred print

Ribbon wrinkle

Ribbon end error

Label feed failure

Communication error

Problems

Cause

Solution

1. Broken element of print head

2. Broken wires of print head cable

3. Failure of the CPU PC board

1. Poor quality of media.

2. Dust is attached to the media.

1. Poor quality of the ribbon

2. Ribbon is not rewound or fed

smoothly.

1. Poor quality of the ribbon.

2. Improper voltage applied to the ribbon

end sensor.

3. Failure of the ribbon end sensor

4. Failure of the circuit which controls

the ribbon end sensor.

1. Paper is not set properly.

2. Paper of poor quality

3. Improper adjustment of the feed gap

sensor or black mark sensor.

4. Failure of the feed gap sensor or

black mark sensor

5. Labels cannot be stripped off the

backing paper or the backing paper

with labels cannot be wound properly.

6. The cutter mechanism is not installed

properly.

7. Failure of the stepping motor

1. Failure of the communication cable

2. Failure of the RS-232C connector

3. Failure of the communication

connector

4. Failure of the PC or application

software

5. Failure of the CPU PC board