INSTALLATION

Site

The floor area designated for headlamp testing requires careful selection and preparation. For MOT requirements the

vehicle standing area and the equipment area where the rails are to be fitted must be level as follows:

Rails +/-2mm

Standing Area +/-6mm over 3 metres.

For non MOT requirements the vehicle standing area does not need to be precisely level as a slight continuous

gradient, maximum 0.4% will not affect accuracy.

NOTE: Preparation of the site to these standards is the customer's responsibility.

Installing Rails

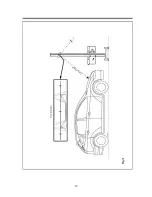

Two sets of rails, each secured to the floor by screws and plastic rawlplugs. The rails are positioned at right angles

to the vehicle's longitudinal axis. The two rails must be levelled with each other, shimmed as necessary, and re-

checked after tightening down. In the final position the rails must be level /-2 mm.

Where the vehicle tested, or any other traffic, will pass over the rails, each rail must be recessed into the floor and

fully supported along its entire length by grouting as necessary, see Fig. 2. It is helpful if lines are painted on the

floor at 90 degrees to the Tester's rails to enable the accurate positioning of vehicles for testing.

Levelling the trolley

The two rear wheels are equipped with an integral cams which are factory set and normally do not require

adjustment. The level can be checked placing a spirit level on the trolley base together with the use of a plumb line

attached to the column. Should any adjustment be required the cams can be adjusted as follows (See Fig. 3):

Loosen screw 1 and just slacken screw 2.

Raise or lower the wheel as necessary.

• Fully tighten both screws.

Re-check level of trolley base using a spirit level.

Re-check that the column is vertical, using a plumb line.

5