4

5

11. Position the block of packing wood at the slave column end

of the base frame, as per Step 7, and stand up the column as per

Step 8. Measure the height of both the drive and slave column

carriages and adjust by rotating the chain sprocket on the slave

column until they are the same height. Move the slave column

toward the drive column about 80 mm and fit the chain to the

sprocket. Move the column back again until the chain is tight,

then remove the packing wood as per Step 9.

12. Bolt the slave column down as per Step 10. Measure the

lean on the drive column and the slave column using a plumb

line. Each column should lean outwards between 14 and 26 mm

from top to bottom. Sideways lean should be a maximum of 5

mm off vertical.

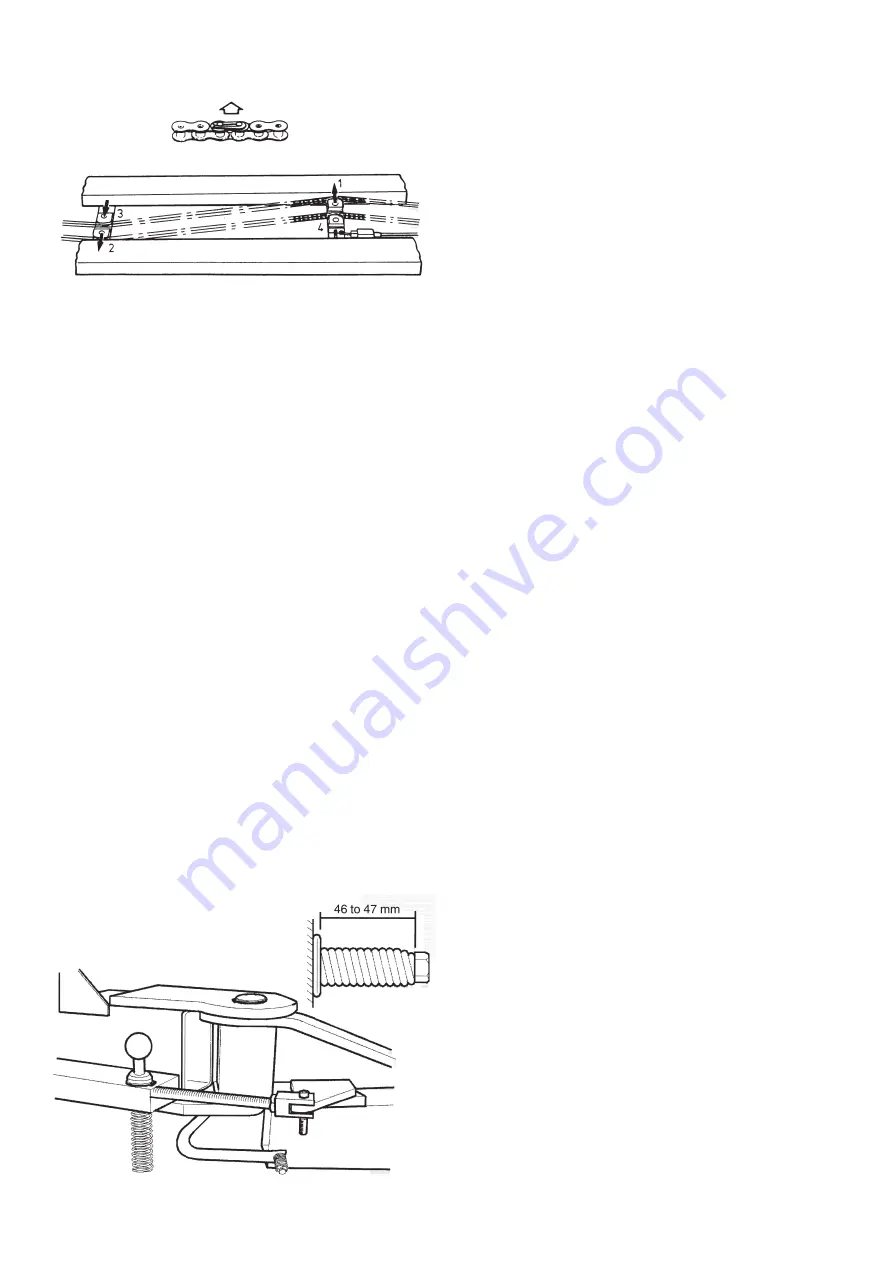

13. Tighten the chain by adjusting the four chain guides in the

order shown in Fig.2 until the spring on guide No.4 is just fully

compressed.

Note: to allow the spring to compress, the square locking plate

at the end of the spring must be held vertical by pushing the

top of the plate towards the No.4 chain, guide. Do not over-

tighten the chain, as this will shorten the life of the chain and

guides.

14. Fit the chain limit switch into position, with the limit switch

roller pushing on the plate beside the chain tension spring.

Retain with two M4 x 25 mm long screws. Check the limit switch

roller can still be moved 2 mm to 4 mm clear of the plate before

running out of travel.

15. Apply a smear of grease in the lifting arm pivot holes and the

carriage pivot holes. Fit the lifting arms to the carriages. Fit the

pivot pins and retain with a circlip top and bottom as per Fig.3.

Check the circlips are fully in their grooves.

16. Fit the footguards to the lifting arms as per Fig.3 and tighten

the bolts until the spring is compressed to a length of 46 to 47 mm.

17. Fit the tool trays to 2 of the lifting arms with the M6 x 16

screws and Ø19 x 2 mm thick flat washers.

Do the screws up snug tight only, (over tightening will distort

the tray). Check the arms slide in and out freely.

18. Place a lifting pad in the hexagonal hole in each lifting arm.

19. Fit the armlock devices to the carriages and arms as per

Fig.3. Check that the circlips are fully in their grooves and the

Nyloc nut is tightened up fully on the M8 x 55 mm long cap

screw. Lift up on each black knob and check each arm moves

freely through the full arc. Release the knob and check the arm

is locked.

20. Fit the cover over the bottom limit switch and tee piece

using two M6 x 10 mm long socket head cap screws. Fit the

motor cover over the vee belts and secure with the M4 x10 mm

long screw and large flat washer.

21. Connect the power supply from the mains isolator switch,

adjacent to the hoist, to the control box on the drive column.

Use the cable gland supplied in the control box to seal the cable

entry in the control box.

Note: This must be done by a qualified electrician.

For a three phase hoist, use 3-core plus earth, 7- strand, 2.5 mm²

copper cable and connect the three active wires to the terminal

strip in the control box. Connect the earth (green) wire to the

earth terminal.

For a single phase hoist, use 2-core plus earth, 7- strand, 4 mm²

copper cable. Connect the active (brown) wire to terminal 1, L1,

on the contactor. (marked K1M). Connect the neutral (blue) wire

to terminal 5, L3 on the contactor. Connect the earth (green)

wire to the earth terminal.

22. Switch on the power to the hoist. Turn the operating switch

to up. The hoist should go up. If it goes down, stop immediately

and turn off the mains isolator, for a three phase hoist, swap two

of the power supply wires at the terminal strip in the control

box. For a single phase hoist, check that the active and neutral

wires have been connected to the correct terminals. Switch the

power back on.

23. Drive the hoist fully up to check operation of the top limit

switch. Drive hoist fully down to check operation of the bottom

limit switch. Swing the four lifting arms in and out with the

lifting pads screwed fully down. If the arms hit the floor in any

position, adjust the arm on the bottom limit switch so the lifting

arms clear. Loosen the chain and try operating the hoist –it must

not operate! Retighten the chain as per Step 13.

24. Apply a liberal amount of oil to the chain and to the slideway

of the spring-loaded chain roller. Fit the drive on ramp and bolt

it down with the M8 x 16 screws and flat washers.

25. Drive the hoist up 1 m clear of the floor. Fit a funnel through

the hole in the front blind in the drive column. Pour in a half a

litre of the recommended extreme pressure oil (supplied). Pour

the other half litre into the slave column.

Note: 1⁄2 litre of oil will half-fill the oil reservoir in each column.

Do not have the reservoirs more than half full as the excess oil

will be quickly lost.

26. Drive the hoist up and down four or five times to lubricate

the lifting screws.

The hoist is now ready for operation.

Fig.2

IMPORTANT:

Link must be seen from

the top when installed.

FIG. 3