EU – 401N User’s manual v 1.1.3

-

12

-

Example:

If the gear coefficient value is 3, each 3°C difference between the tank temperature and the collector

temperature results in 10% increase in pump speed.

The table below contains examples of the coefficient values and its results.

Gear coefficient 3 Gear coefficient 4 Gear coefficient 5 Gear coefficient 6

Pump

working

revolutions

Δ

value

(collector temp.

– tank temp.)

Δ3

Δ4

Δ5

Δ6

10%

Δ6

Δ8

Δ10

Δ12

20%

Δ9

Δ12

Δ15

Δ18

30%

Δ12

Δ16

Δ20

Δ24

40%

Δ15

Δ20

Δ25

Δ30

50%

IV.c.6)

Solar pump work minimum

This parameter is available only if regulated revolutions option is selected. Using this setting the user

should define the pump minimum initial speed.

IV.c.7)

Solar pump work maximum

This parameter is available only if regulated revolutions option is selected. Using this setting the user

should define the pump maximum operating speed (%).

IV.c.8)

Installation sampling

This function enables the user to activate or deactivate circulation sampling, aimed at updating the

temperature reading, by activating the collector pump for a short period of time (when standard

conditions of pump activation are not met). Sampling forces short-time activation of the pump after

the collector temperature increase of at least 3°C.

IV.c.9)

Control revolutions

These parameters enable the user to choose the type of PWM pump used:

•

Increase

It concerns PWM pump whose speed increases when the signal increases.

•

Decrease

It concerns PWM pump whose speed decreases when the signal increases.

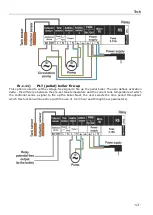

IV.d)

Peripherals

The user may connect and configure the settings of an additional device. If there is no additional device,

the user should select NONE (deactivate). Additional devices to choose from and examples of

connections supporting all available installation schemes are presented below. In the case of schemes

12 and 14 it is not possible to connect an additional device - the function is unavailable.

IV.c.10)

Circulating pump

Once this device is selected, the user should adjust

operation time

and

pause time

of the pump during

its activity. Next, the user should define the hours of pump operation using

From hour

and

Through

hour

functions. Entering the same times (from – through) will result in the device being active

throughout the whole day.