16

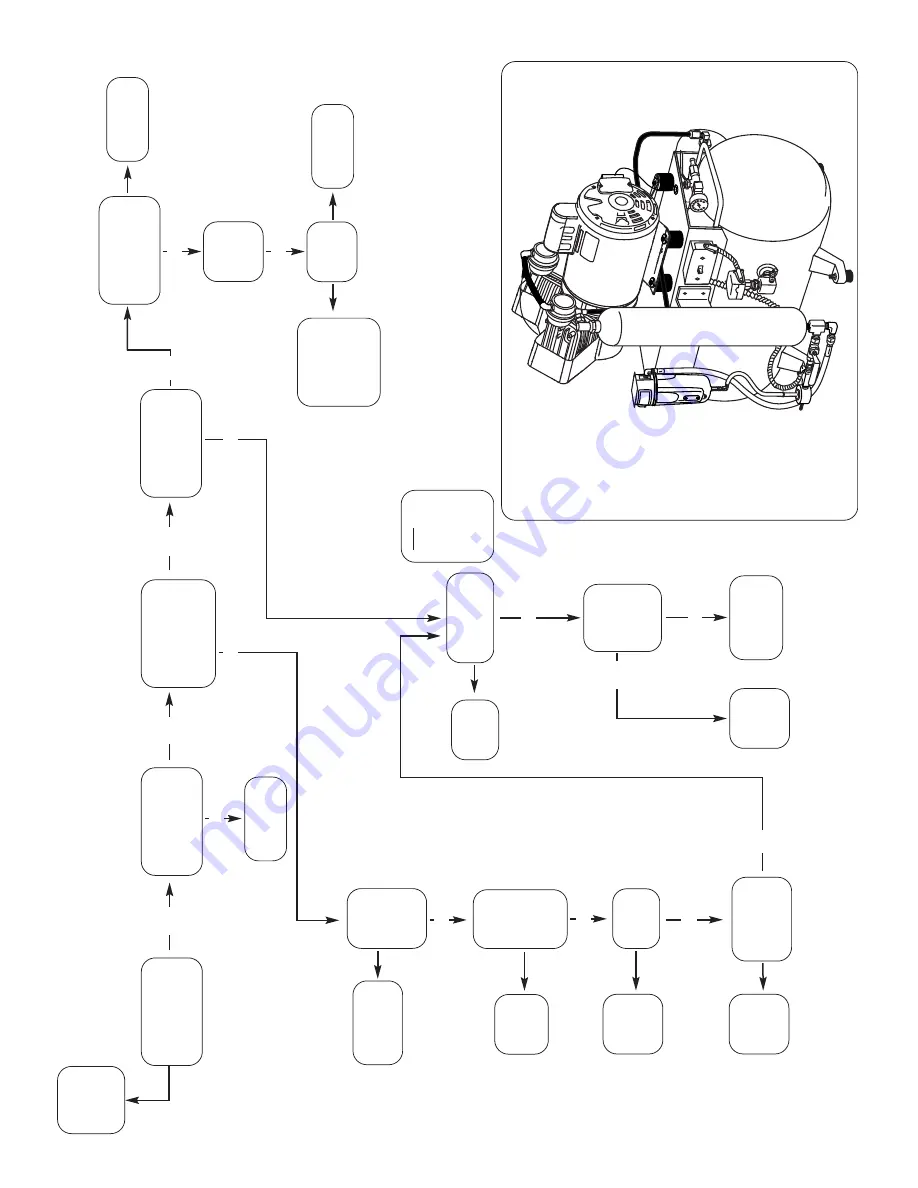

DOES AIR

COMPRESSOR

RUN?

Does compressor run

for a few seconds,

“chugs”, then stops?

Does compressor pres-

surize from 80 to 100

psi in less than 2

minute with no air

being used?

Does compressor

cycle with no air

being used?

YES

NO

YES

NO

GO ON T

O

THE NEXT

P

AGE.

Are there leaks in

compressor or in

of

fice piping system?

Does air

bleed out

the purge

valve when

unit is

running?

Clean

or

replace.

Replace

intake

filter

.

NO

NO

Check voltage at

the valve and

make sure valve is

closed.

Does

unloader

valve pres-

sure switch

or float

assembly

seat while

running?

NO

YES

Tr

ouble Shooting Chart

Single Ultra Clean Oilless Compressor

Single Ultra Clean Oilless Compressor Diagram

YES

Is the moisture

indicator pink?

YES

Is intake

filter

clogged?

Is there suf

ficient

pressure build-up

with head

discharge line

removed?

YES

NO

Defective

head,

contact

Tech W

est.

Note:

Close

shut of

f valve.

Pump up tank to

100 psi. If pres-

sure is main-

tained for 15-20

min., leak is in

of

fice lines.

YES

Locate and

repair

.

NO

NO

Does

purge valve

system

function

properly?

YES

Does com-

pressor run

too hot or too

frequent?

NO

Check for proper

voltage. Use buck-

boost if needed.

NO

1. Locate and repair

leaks.

2. V

entilate if room is

above

100 deg. F

.

3.

Contact

compressor

may be undersized.

YES

YES

Service dryer and

replace moisture

indicator

.

YES

Check voltage sup-

plied to the

compressor

.

YES

Defective

head,

contact

Tech W

est.

YES

NO

Does air leak

from unloader

valve or the

purge muf

fler

continuously

until unit cycles

again?

Make sure that the

dryer valve is clos-

ing properly

.

Summary of Contents for ACO2S

Page 2: ... ...

Page 10: ...8 8 7 6 9 1 2 3 4 5 ULTRA CLEAN OILLESS COMPRESSOR PARTS LIST ...

Page 24: ...22 Maintenance Service Notes ...

Page 25: ...23 Maintenance Service Notes ...

Page 26: ...24 Maintenance Service Notes ...

Page 27: ...25 Maintenance Service Notes ...