TS8200D Series

Micro-Meter Mix Quick Start Guide

h.

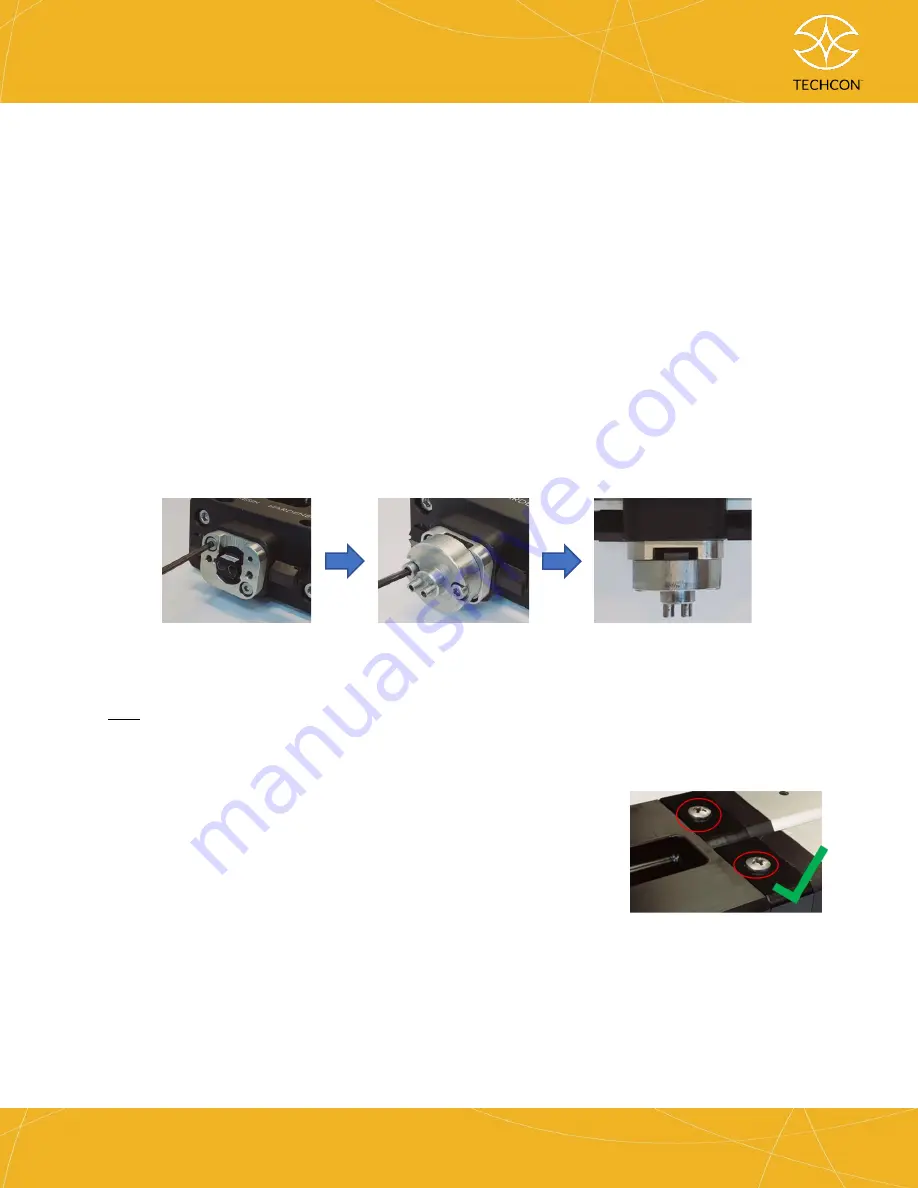

Install calibration adaptor. The calibration adaptor is required whenever

calibration is performed, when a new fluid is introduced, when the valve is

disassembled & reassembled, or when the stators or rotors are changed.

Connecting calibration adaptor can protect the TS8200D from having direct

contact with the material as it exits the pump.

i.

Mount the 1:1/2:1 K-type Nozzle Locking Plate and use a 2.0 mm hex wrench to

fasten screws into place.

i.

Mount the calibration adaptor and use a 2.5 mm hex wrench to fasten screws

into place.

ii.

Make sure that the calibration adaptor rest evenly against the nozzle locking

plate.

2.

DISPENSING

Tip:

Avoid over-tightening vent screws. Over-tightening may lead to tears to the

vent seal O-ring.

a.

Connect the fluid supply to the fluid inlet of the pump. If

using a fluid reservoir, reference the

“Accessories”

Section for information on compatible fluid lines. Make

sure the r

esin is connected to the pump with the “RESIN”

label and the hardener is connected to the pump with the

“HARDENER” label.

b.

Connect the pump to the controller.

4