13

6.3 Cartridge Kit Preparation

Injection Kit:

The TS6500 Mixer has an automatic injection

device that will inject the hardener into the catalyst during the

mixing operation. However the valve in the mix rod needs to be

opened before placing the kit in the machine. Follow below

instructions to open the valve.

1. Insert the ram rod into the mix rod

2. Push the ram rod to force the valve opened

3. Follow instructions in section 6.4 to mix the injection kit

Barrier Kit

1. Remove barrier tape from the kit

2. Pull the mix rod down to the fullest extend to remove the foil

from the dasher.

3. Follow instructions in section 6.4 to mix the barrier kit

Barrier tape

Dasher

Foil

Mix Rod

Figure 10.0 Barrier Kit

Valve

Mix Rod

Figure 9.0 Injection Kit

14

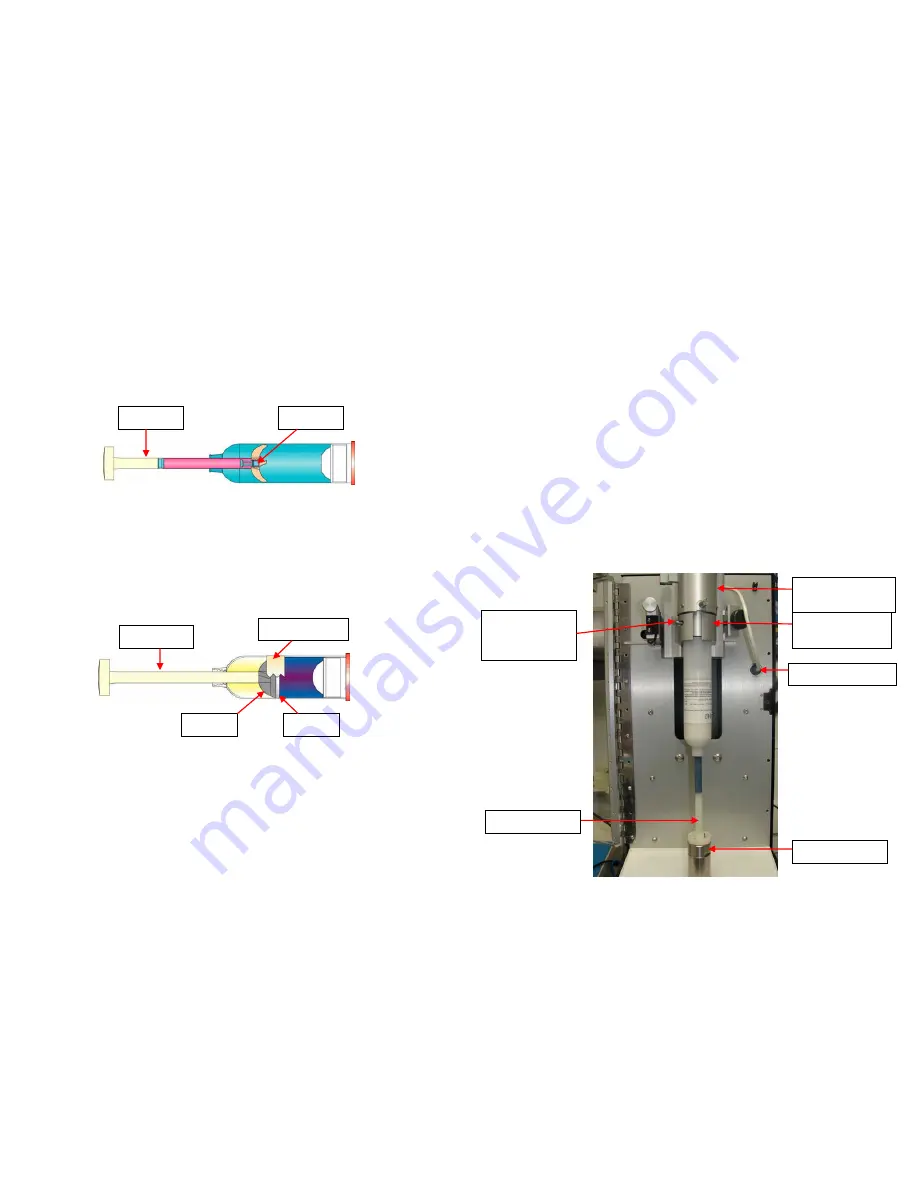

6.4 Loading the Cartridge Kit

Note:

a. The unit is setup to mix cartridge kit with 8”(203mm) mix

rod. To mix cartridge kit with 6”(152mm) mix rod, the

spindle extension needs to be installed. Refer to section

6.5 for instructions.

b. The TS6500CIM-6 is setup to mix 6 oz. (177ml) cartridge

kit. To mix 2.5 oz. (74ml) or 8.0 oz.(237ml) kit, Refer to

section 12. for instructions.

1. Open the safety cover (Fig. 2, 12).

2. Load the cartridge kit into the cartridge holder (Fig. 2, 2).

3. Pull the mix rod to the fullest extend then align the two

through holes of the rod to the drive spindle (Fig. 2, 6).

4. Insert the plunger assembly (Fig.2,16) into the cartridge

holder with the plunger sit properly inside the cartridge.

5. Align the dowel pins of the plunger assembly with the

bayonet slots in the cartridge holder and turn

counterclockwise until it locked in.

6. Connect the air hose into the plunger air inlet (Fig. 2, 4).

7. Close the safety cover.

Plunger

Assembly

Plunger Air Inlet

Mix Rod

Drive Spindle

Cartridge

Holder

Lock Dowel

pins in the

slots

Figure 11.0 Loading the Cartridge Kit