15

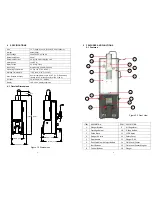

6.5 Spindle Extension Installation

Refer to Fig. 12 and Fig. 13

1. Place the wrench on the motor shaft (beneath the spindle).

2. Place a screw driver between the two locking pins of the

spindle.

3. Hold the wrench and turn the screw driver counter clockwise

to unscrew the spindle assembly.

4. Remove the spindle assembly from the motor shaft

5. Install the spindle extension on the motor shaft by turning it

clockwise

6. Install the spindle assembly on the spindle extension by

turning it clockwise

Figure 12.0. Remove Spindle Assembly

Spindle Assembly

Wrench

Screw Driver

Spindle Extension

Spindle Assembly

Figure 13.0. Spindle Assembly with Extension

16

6.6 Mixed Cycle Program Setup:

Refer to Fig. 5 and Fig 6

1. Press the Mode button (Fig. 5) to select Auto mode.

2. Press and hold the Setup button (Fig. 5) for 3 seconds to

enter setup screen.

3. Press the Setup button (Fig. 5) to move the cursor to the

“CYCLE” indicator.

4. Press the (+) and (-) button (Fig. 5) to set number of mixed

cycle required

5. If delay time is required, press the Setup button to move the

cursor to the “DELAY” indicator then press the (+) and (-)

button to adjust delay time

6. Press and hold the Setup button for 3 seconds to save data.

The unit is now ready to run.

6.7 Start the unit

1. Ensure the unit is in the Automatic Mode and the desired

profile has been selected.

2. Press and release the Start buttons (Green) (Fig 2, 7)

simultaneously.

3. The unit will run the selected profile. The cycle count and

elapsed time will be displayed on the LED screen.

6.8 Unloading The Cartridge Kit

1. The machine will automatically stop once the mixing cycles

are completed.

2. Open the protective cover (Fig. 2, 12)

3. Remove the retaining collar plunger assembly (Fig.2, 16) by

turning it clockwise.

4. Place the retaining collar plunger assembly on the side

bracket

5. Turn the cartridge kit clockwise to remove it from the drive

spindle

6. Pull the cartridge kit out of the cartridge holder

6.9 Manual Mode

While in the manual mode, the injection rod, main cylinder and

drive spindle motor may be controlled independently. Note: while

in manual mode any errors will not halt the operation of the

motors. Refer to Fig. 14

1. Press and hold the Mode button for 3 seconds to select

Manual mode

2. Press the Power (-) button to activate the injection rod (the

injection rod will move up)

3. Press the Mode button (+) to activate the motor (the drive

spindle will rotate)