17

4. Press the Setup button (

↵

) to activate the main cylinder (the

cartridge holder will move up and down)

7 SPEED

CONTROL

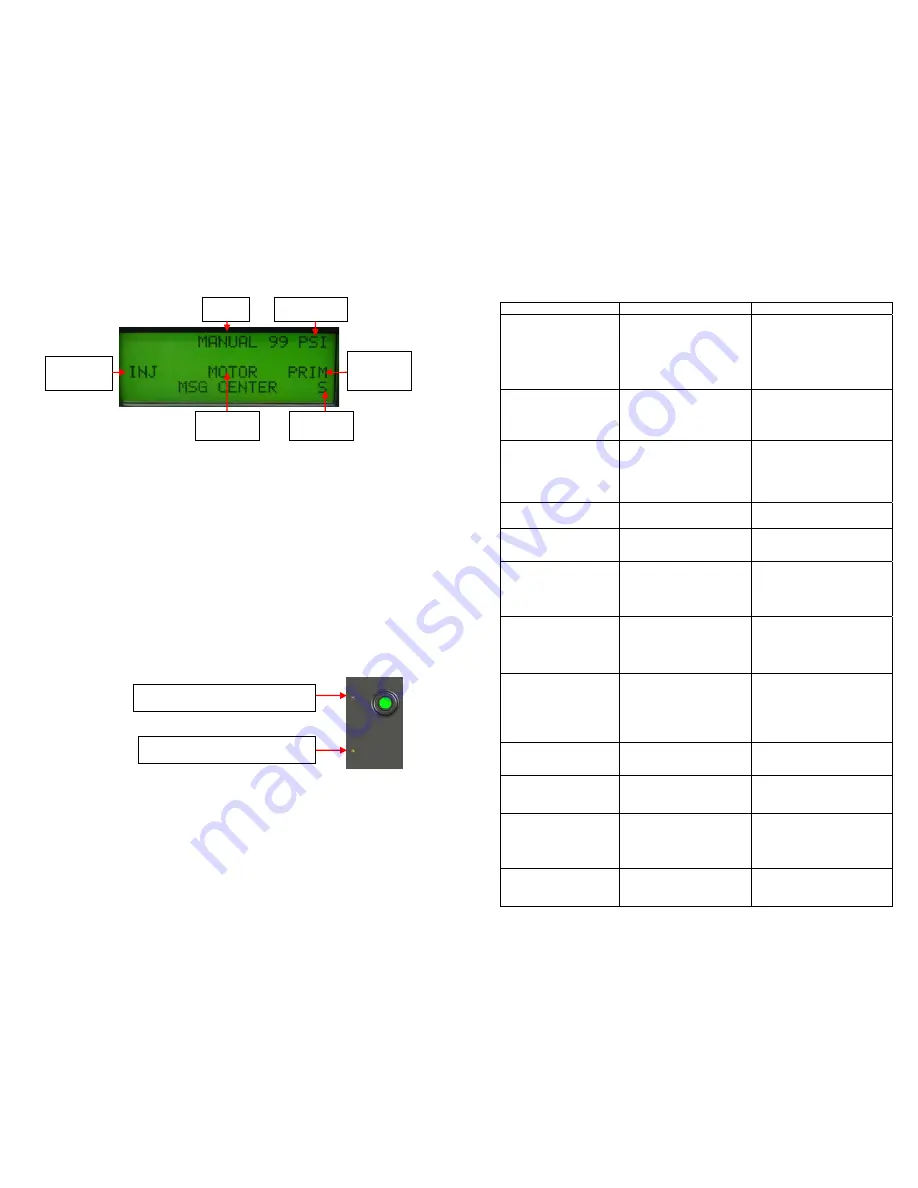

7.1 For main air cylinder

The main air cylinder drives cartridge kit up and down. The

stroke speed of the main air cylinder can be adjusted by rotating

the flow control screw (Fig. 15) clockwise to increase the speed

and counterclockwise to decrease the speed

7.2 For injection rod

The injection rod air cylinder drives the injection rod up and

down. The injection speed can be adjusted by rotating the flow

control screw (Fig. 15) clockwise to increase the speed and

counterclockwise to decrease the speed

8 EMERGENCY

STOP

In case of an emergency, the mixing operation can be stopped at

any time by pressing the EMERGENCY STOP BUTTON, (Fig 2, 10).

After problems have been fixed, the machine can be restart by

pulling and turning the emergency button counter clockwise. The

mix cycle will start from the beginning.

Main Air Cylinder Flow Control

Injection Rod Flow Control

Figure 15.0 Side View

MODE

Figure 14.0 Manual Mode Screen

ACTIVATE

INJECTION

ACTIVATE

MOTOR

SAFE TO

RUN

ACTIVATE

MIX

CYCLE

PRESSURE

18

9 TROUBLESHOOTING

PROBLEM POSSIBLE

CAUSE

CORRECTION

Unit fail to start

•

No power input

•

Emergency

button

is

pressed

•

Safety door is not

fully closed

•

Check power cord

connections

•

Turn

Emergency

button clockwise to

release

•

Closed

safety

door

LCD does not light

•

No power input

•

Check power cord

connections

•

Check

Fuse

•

Turn on power

Air Cylinder does not

move

•

Insufficient

air

pressure

•

Air hoses not

plugged in

•

Regulator

defective

•

Increase air supply

pressure to 80 psi

•

Check air connection

•

Replace

regulator

The hardener is not

completely injected

•

Air cylinder is

damaged

•

Replace air cylinder

The injection rod does

not retract

•

Injection rod is dirty

•

Injection rod is bent

•

Clean

rod

•

Replace

rod

Material is not

completely mixed

•

Not enough mixing

cycle

•

Insufficient

air

pressure

•

Increase number of

cycles

•

Increase air pressure

to 80 psi

Cartridge holder is not

in “Home” position

•

Insufficient

air

pressure

•

Air hoses not

plugged in

•

Increase air supply

pressure to 80 psi

•

Check air connection

Mixing rod does not

reach spindle

•

Extension spindle is

not installed for 6”

rod

•

Mixing rod in not fully

extend

•

Install

extension

spindle for 6” rod

•

Extend

mixing

rod

No pressure on

plunger

•

Plunger air hose is

not connected

•

Connect plunger air

hose

Plunger disk does not

fit inside cartridge

•

Wrong plunger disk

size

•

Use correct plunger

disk size

Cartridge holder

remains in the down

position during mixing

cycle

•

Sensor and magnet

is not aligned

•

Turn off unit and adjust

sensor / magnet

alignment

Motor is not running

•

No power to motor

•

Motor burned out

•

Check

motor

connection

•

Replace

motor