- 20 -

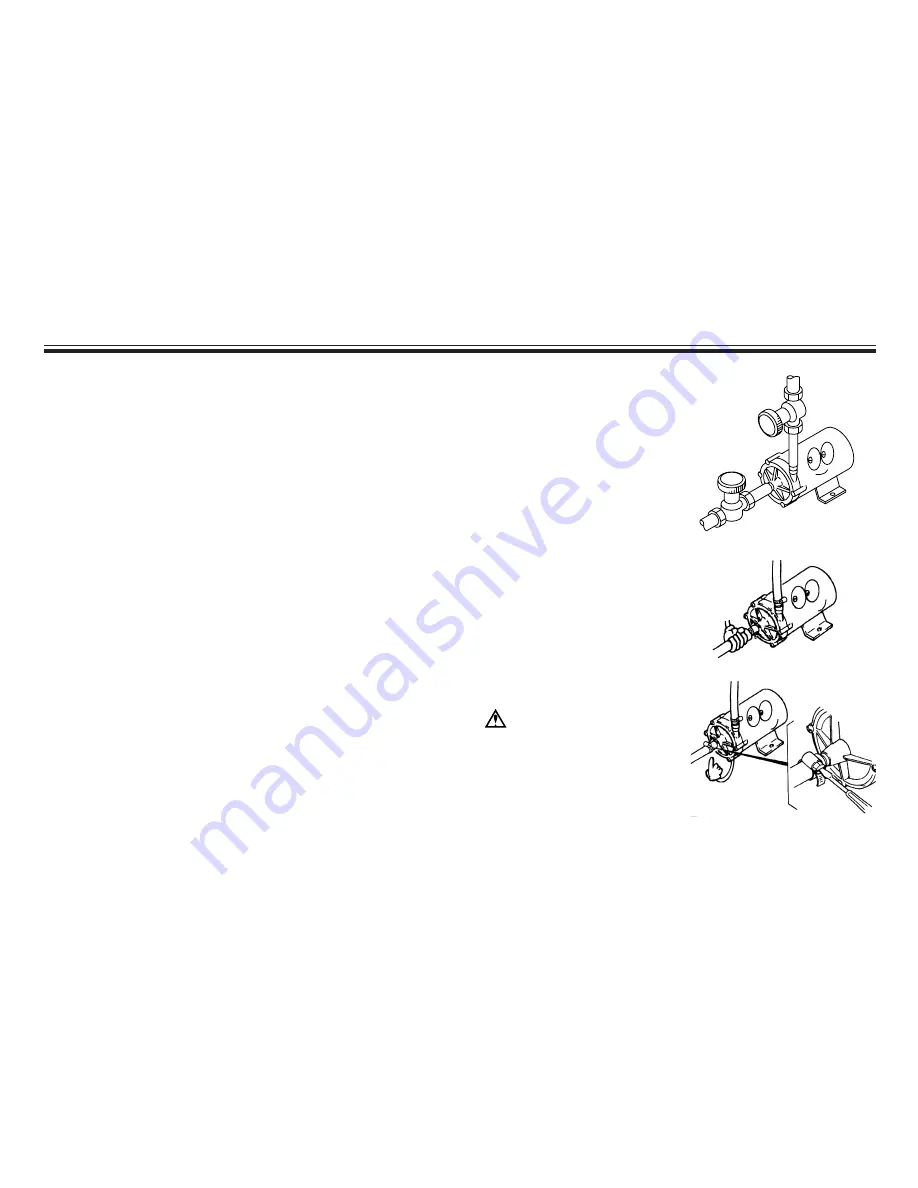

10-2. Piping

Piping instructions

(1)

To minimize the friction resistance, the shortest piping possible

with the minimum number of bends should be utilized. Especially

for suction piping, employ as larger and shorter hose as possible.

(2)

Use a corrosion-resistant vinyl hose that can endure the pressure

made by the pump operation.

If the connection on the suction side is inadequate, air may be

mixed in.

(3) Hose size

Select a hose in accordance with the diameter of the pump port.

A reliable connection is not guaranteed if different size of hose is

used.

As the hose on the suction side, in particular, tends to be crushed

under the sucking force, the use of a braided hose is recommend-

ed. (In the case of hot liquid feeding, special attention must be

paid in the selection of a hose.)

(4) Valve installation

Install valves close to the suc-

tion and discharge port.

· Suction side valve:

For easy removal or mainte-

nance of the pump.

· Discharge side valve:

For adjustment of the dis-

charge rate or head.

(5) Hose connection

Press the hose end firmly

against the discharge or suc-

tion port until it reaches the

bottom of the port.

*Use a fastener (such as a

hose band) to make the con-

nection firm and free of liq-

uid leakage.

Caution

Do not tighten the connec-

tion ports (suction and dis-

charge) excessively as they

are made of plastic resin

and are easily damaged.

Summary of Contents for FSSR1

Page 1: ...Issue 1 02 07 FSSR1 Venturi Scrubber Unit OPERATOR S MANUAL ...

Page 7: ...1 Appendix 1 Scrubber Layout ...

Page 8: ...A3 ...

Page 9: ...Appendix 2 Operating and Maintenance Instructions for Pump ...

Page 10: ...Read this manual before use of product MD SERIES Instruction Manual IWAKI Magnetic Drive Pump ...