2. Screen the medium through a 50 to 70 mesh sieve before returning it to the cleaned bath. This removes

scale, agglomerated medium, char, undegraded polymer and lost parts and helps maintain a good

quality of fluidisation.

HALF-YEARLY INTERVALS

1. The bath should be emptied, cleaned, inspected and the medium replaced by a fresh charge.

2. Alternatively, if the facilities are available, the medium may be thoroughly washed in several changes

of clean water, washed through a 70-mesh sieve, drained, dried and returned to the bath where drying

is completed by fluidisation and heating at 150°C, until the medium fluidises in the normal manner.

The washing procedure removes acidic residues and accumulated soluble salts and residues.

Symptoms of neglect should be dealt with immediately. These include: pitting of metallic surfaces,

formation of lumps of agglomerated medium, accumulation of polymer or polymer filler material,

indications of bad or uneven fluidisation, blockage of the fluidising plate and wetness or stickiness of the

medium.

FAULT FINDING

Any service or repair work should only be carried out by a trained electronic or electro mechanical

technicians. Untrained personnel should not attempt to dismantle this equipment.

If the heater indicator fails to go off, the unit fails to reach its operating temperature or heat up rate

decreases, check:

1. Fluidization – remove aluminium oxide from bath leaving approximately 50mm (2”) in the bottom. If

an area of one quarter or more is not bubbling, then most likely the porous plate is blocked and should

be replaced. Check that the porous plate is not blocked with plastic residue or other material.

2. Heater - Empty medium from the bed and disconnect the main supply. Turn the unit upside down and

check the resistance of the heater. If one or more heater windings are faulty, replace the heater.

Reassemble in the reverse order.

3. Thermocouple – check with an instrument that can measure and simulate thermocouple signals to

verify its operation.

4. Controller and/or SSR – the controller will output a DC signal to the SSR when heat is called for. If the

SSR is receiving a DC control signal but not passing power to the heaters, then it should be replaced.

Alternatively, a problem may exist with the controller. If the fluidization deteriorates, check the air filter

assembly for clogging of the filter element; if necessary, replace the element.

If the fault remains, run your bath at 600°C (1100°F) for a period of one hour to allow any accumulated

residue in the bath to burn off. If the fault persists, empty the medium from the bed, check the stainless

steel porous plate for damage due to clogging by plastic residue, distortion of the plate or corrosion.

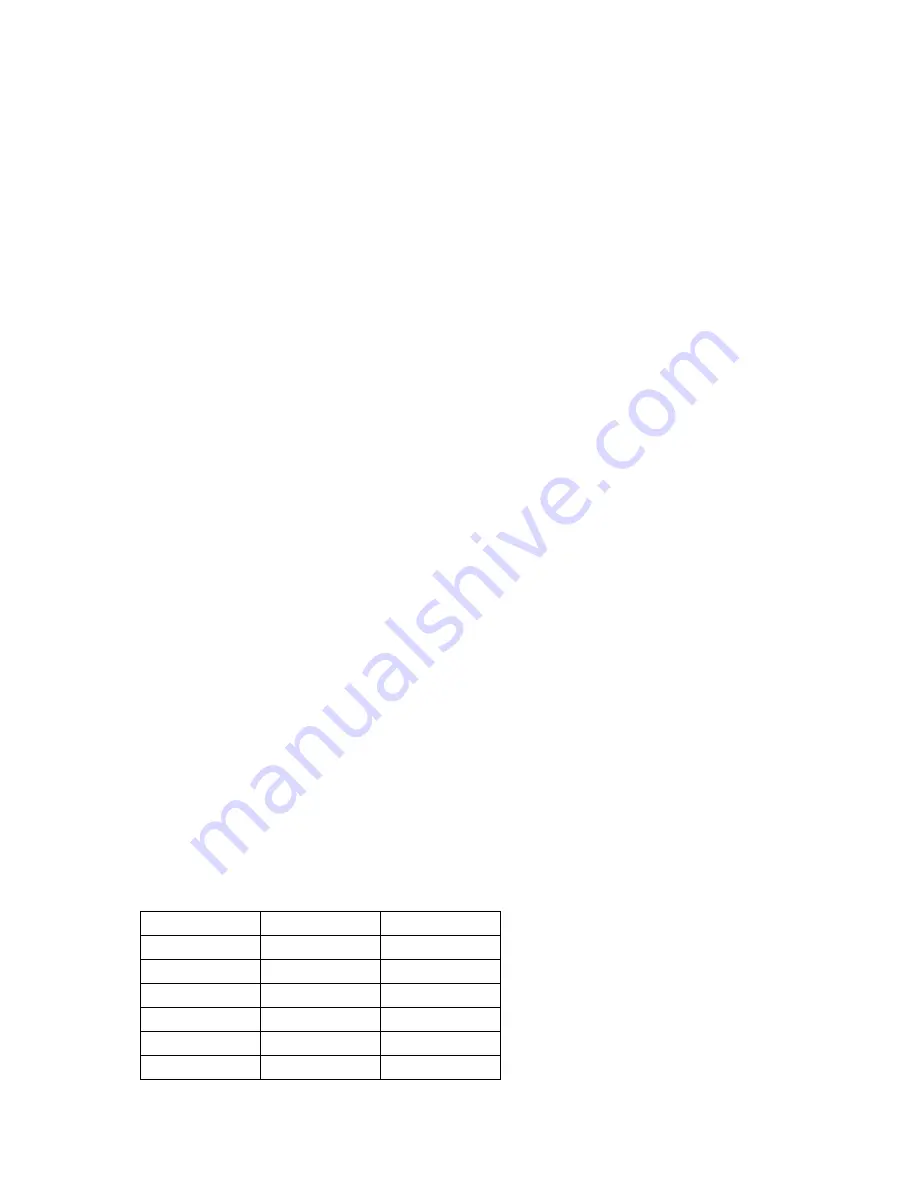

Factory PID Parameters (For IFB51 S/N: 451 and higher, IFB52 S/N: 214 and higher)

Parameter

IFB-51

IFB-52

Pb

15

12

Ti

450

480

Tg

75

80

1PLS

5.0

5.0

CBHI

20

20

CBLO

20

20

27