GB

10

5.6.3 - SETPOINT ADJUSTMENT

• Simultaneously press buttons (

1

) and (

2

) for at least 2 seconds, "

SET

" is displayed.

• Press the 2 buttons again, "

Coo

" is displayed. Using button (

1

) or (

2

), display either "

HEA

" or "

Coo

" corresponding to

the heating setpoint ("

HEA

") or cooling setpoint ("

Coo

").

• Simultaneously press the 2 buttons again for 2 seconds. The setpoint value appears. If needed, modify the value with

the buttons.

• Press the 2 buttons simultaneously to validate the setpoint.

• Return to the normal display by simultaneously pressing the 2 buttons for more than 2 seconds.

Reminder: control on the installation return temperature.

Note:

All units are factory configured and parameterized for optimum operation in the terminal unit application.

5.6.4 - DISPLAY OF TEMPERATURES, ALARMS, AND HOUR COUNTERS

Accessible directly via the menu, see diagram 5.6.2.

• Temperatures "

TP

:

Displays the values indicated by each temperature probe:

t01

: water inlet temperature.

t02

: water outlet temperature.

t03

: exchanger air temperature.

t04

: outside air temperature.

• Alarms "

Err

":

Displays the list of all current alarms (scroll through the alarm messages with buttons (

1

) and/or (

2

)).

• Hour counters "

OHr

":

Displays the operating time of the compressor ("

OH1

") and the circulating pump ("

OHP

"). The counter can be reset by a

long press (> 2 seconds) on button (

1

) when the counter value is displayed.

5.6.5 - ACCESS TO THE TECHNICAL PARAMETERS "PAR"

For qualified personnel after entering the password "PSS". Any incorrect adjustment may lead to serious

malfunctions.

• Go to the "

PSS

" section in the menu. Briefly and simultaneously press buttons (

1

) and (

2

). The "

---

" message appears.

Display the password ("

199

") using buttons (

1

) and (

2

) and validate it by simultaneously pressing buttons (

1

) and (

2

). It

is now possible to enter the parameters section "

PAr

".

CAUTION:

After modifying one or more technical parameters, the controller must be turned off then back on again to reset

it with its new parameters.

5.7 - ALARMS

• When an alarm occurs:

- the alarm report is activated,

- the corresponding code flashes on the display unit. See table,

- the unit stops if necessary (see table below).

• Remedy the fault.

IMPORTANT NOTE:

All work must be carried out by qualified, experienced personnel.

• The alarms are normally reset automatically.

•

CAUTION

: the alarms:

- HP,

- LP (low pressure),

- Anti-freeze,

- Water flow rate

have an event counter that shifts to

manual

reset if the alarm occurs several times during the last hour.

• The "refrigerating circuit" alarm is reset manually.

• The alarms are reset by briefly pressing the "

ON/OFF

" button (

1

).

• When the alarm is cleared:

- the alarm report is de-activated,

- the display reverts to normal (not flashing),

- the machine can re-start (if it was stopped).

• Special features of the alarm relay:

- the potential-free change-over contact (2 A - 230 VAC max.), on the terminal strip of the PCB, comes from the relay

located on this board,

- the relay is actuated in the absence of an alarm (contacts: 5/6 closed and 5/7 open),

- in the case of alarm or power supply loss, the relay is released (contacts: 5/6 open and 5/7 closed).

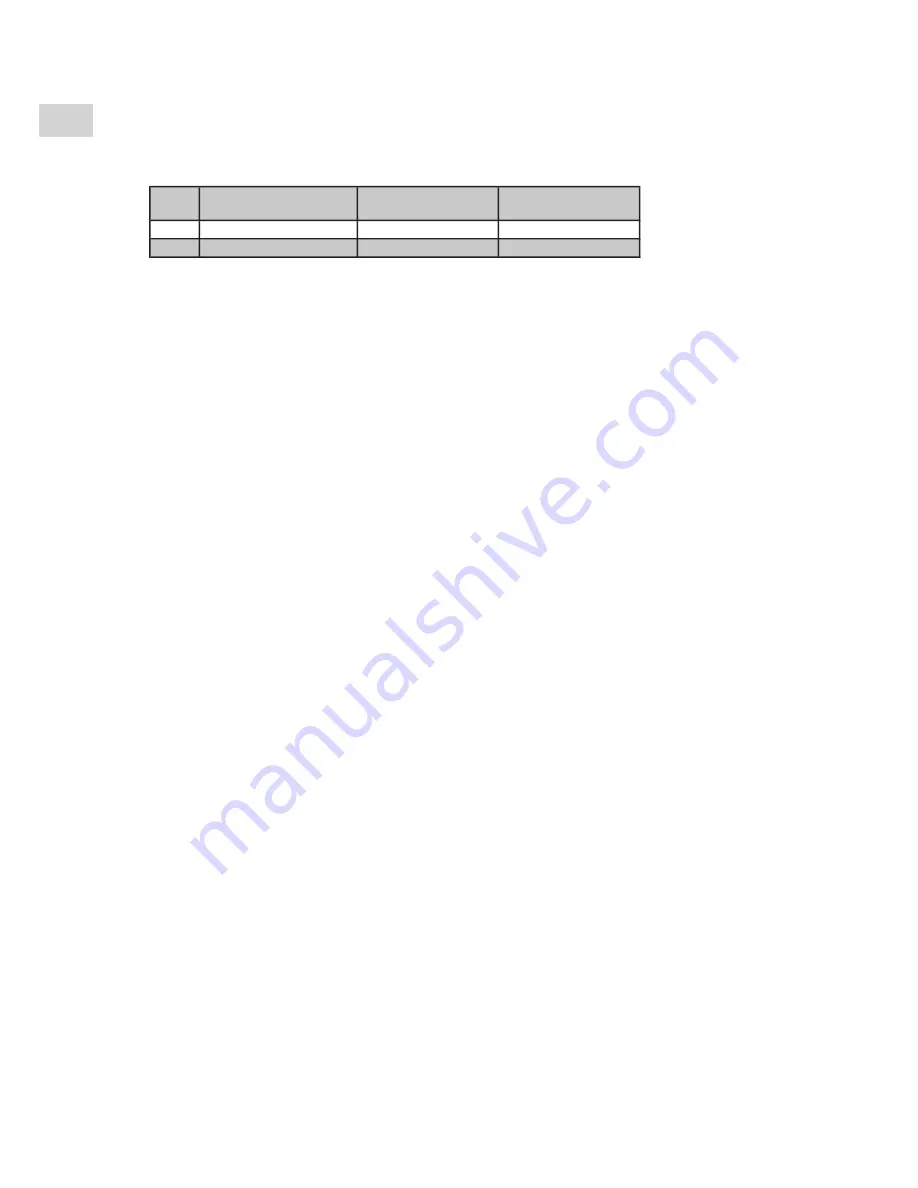

Factory setting

(terminal units)

HEA

Heating set point

4 0

°C

25 to 45°C

Coo

Cooling set point

1 2

°C

9 to 25°C

Parameters

Code

Adjustment range