8. Self Check Function

This unit is equipped with a self check function which can detect a part of

malfunction. Use this function before servicing the unit and check the item as shown

below.

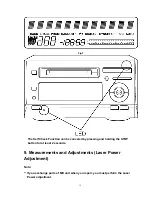

8.1. Setting to the Self Check Function

1. Turn the power on.

2. Press and hold the STOP button for at least 2 seconds, and while still pressing the

STOP button, press the REV. SEARCH button for at least 2 seconds. Then the unit

enters Self Check Function. (Refer to

Fig.3

.)

Fig.3

8.2. Checking the operation switches

1. When the unit enters the Self Check Function, the FL display turn off.

2. Press the buttons on the unit except the INPUT SELECTOR button, it displays “-”

mark adapted each buttons.

(

Fig.4

and

Fig.5

is shown about a allotment.)

17

Summary of Contents for SJ-HD501

Page 3: ...1 Accessories AC power supply cord 1pc Optical cable 1pc RJL1X001B05D 3...

Page 5: ...2 Precation of Laser Diode 5...

Page 9: ...Procedures 9...

Page 10: ...10...

Page 11: ...11...

Page 12: ...12...

Page 13: ...13...

Page 14: ...14...

Page 16: ...Fig 2 16...

Page 27: ...27...

Page 28: ...28...

Page 29: ...29...

Page 30: ...30...

Page 31: ...31...

Page 32: ...32...

Page 33: ...33...

Page 46: ...20 MMOD Connected to GND 46...

Page 59: ...L4 8 RLQU2R2MT W COIL 5 59...