Connection to the gas supply

There are two ways to make the connection to the main gas line:

A. The hotplate can be connected with rigid pipe as specified in

AS5601 table 3.1.

B. The hotplate can be connected with a Flexible Hose, which

complies with AS/NZS 1869 (AGA Approved), 10mm ID, class B

or D, no more than 1.2m long and in accordance with AS5601.

WARNING: Ensure that the hose assembly is restrained from

accidental contact with the flue or flue outlet of an underbench

oven and it does not contact the hot surfaces of the hotplate,

oven, dishwasher or other separate appliance that may be

installed underneath or next to the hotplate. The hose should not

be subjected to abrasion, kinking or permanent deformation and

should be able to be inspected along its entire length. Unions

compatible with the hose fittings must be used and connections

tested for gas leaks.

The supply connection point must be accessible with the

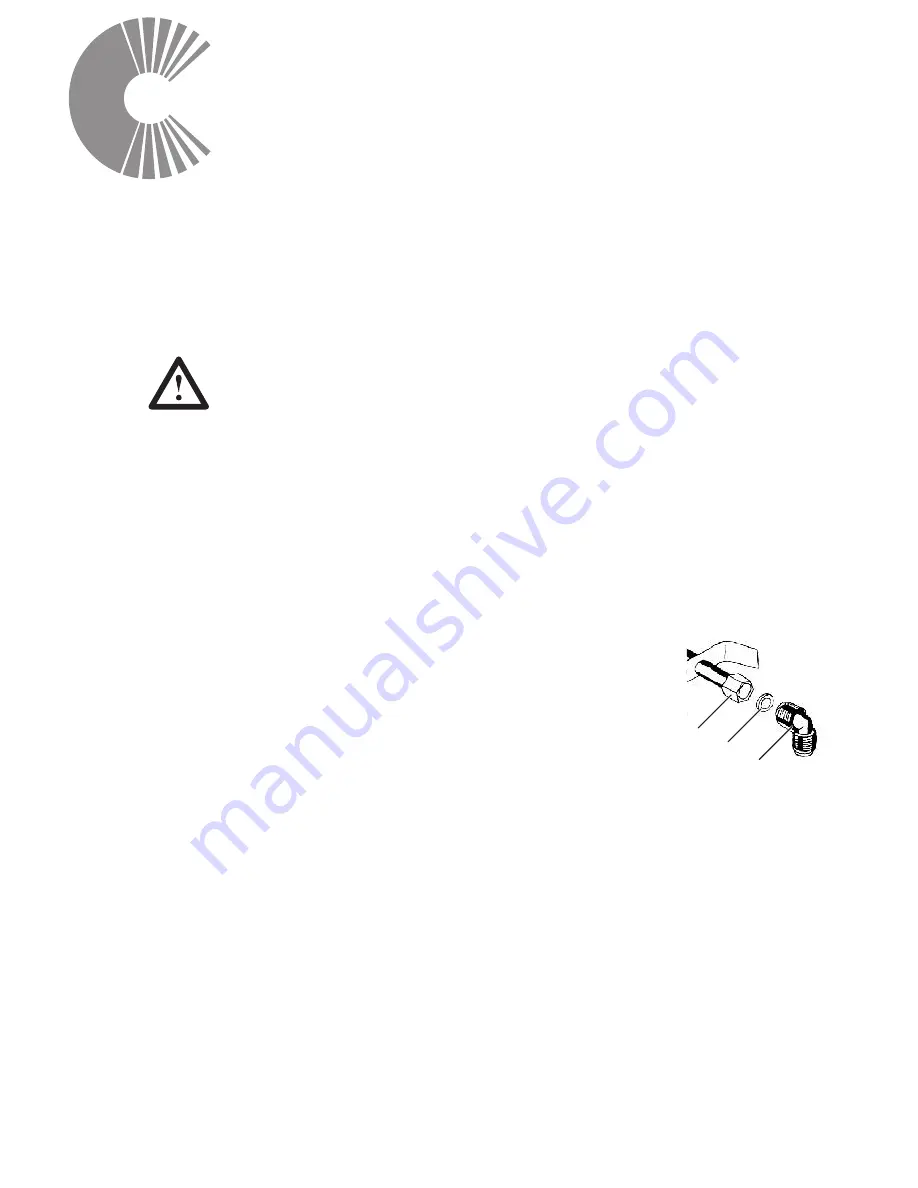

appliance installed. Fit the supplied elbow and gasket as shown in

the illustration right. The gas inlet connection

has a 1/2" BSP male thread. When making

the connection, take care not to apply

excessive stress by counterbalancing

tightening force. Ensure that the available

gas supply is the same as the gas type label

affixed to the base of the hob. If not, contact

Technika for a Gas Conversion Kit. The gas

supply pressure must be adjusted in

accordance with the data label for the gas

type. Adjust the test point pressure with the

largest burner operating at maximum.

Electrical connection

This appliance is designed to operate on a power supply voltage

of 220-240V, single phase and is fitted with a 10A, 3 pin plug.

Before making the connection, make sure that:

1) The electrical system is able to withstand the load of the

appliance (see data label).

2) The power supply system has an earth connection in good

working order in accordance with the regulations in force.

Installation

A

B

C

A - Manifold Nut

B - Gasket

C - Elbow

14