PG 20

PG 21

INSTALLING YOUR NEW COOKER

TECHNICAL SPECIFICATIONS

•

The cooker MUST BE installed and serviced only by an authorised person.

•

A certificate of compliance must be supplied by installer and is to be kept by the customer.

•

The packing materials must be removed before you install the cooker.

•

You must follow the installation instructions in this booklet.

•

The surrounding kitchen cabinets must be able to withstand 85°C. We will not accept responsibility for

damage caused by installation in to kitchen cabinets which cannot withstand 85°C.

•

The appliance must not be installed in a corner. It must be installed at least 100mm from the side wall.

•

The flexible pipe for gas models must have sufficient loops so the cooker can be moved for service.

•

The vents; opening and all air spaces must not be blocked.

•

The anti-tilt plate must be installed to avoid accidental tipping.

•

The 18 stabilising bolt must be installed to avoid accidental moving.

•

You must not pull the cooker by the door handles.

•

Power socket, if provided for gas models, and electricity isolation switch for electric models and gas models

without a 20A plug, is to be installed in an accessible position near the cooker (but not behind cooker).

•

If the supply cord or cable is damaged, it must be replaced by an approved service agent or a similarly

qualified person in order to avoid a hazard.

Unpacking and installation instructions for installer

•

Please check the product and make sure that there is no damage.

•

Read the relevant installation sections of this manual (16,17,18,19). Ensure understanding.

•

Confirm that product is compatible with available electrical/gas supply. Ensure proposed installation position

does not conflict with installation sections.

•

Check the attachment packing in good condition, complete accessories.

•

Use screw driver to remove two fixed anti-tilt plate screws and pate.

Locating the cooker

Study the diagrams below to be sure of the dimensions required to locate the cooker safely. Make sure that the

top of the cooker is at least 10mm higher than the level of the bench tops. The appliance has been designed to fit

in a 550mm wide gap in kitchen cabinets. The cooker may also be installed at the end of a line of benches or with

a free space on either side.

NOTE:

To ensure cooker stability, both the anti-tilt and anti-movement/ stability bolt must be installed on all

cookers (electric and gas).

The splash back installation

•

To replace the splash back, align the 2 tabs of the splash back with the

corresponding holes in the hob and push downwards.

•

To remove the splash back, simply pull upwards.

•

Clean the splash back in hot soapy water

•

If required, pull the cooker back out and adjust the leveling feet as

required.

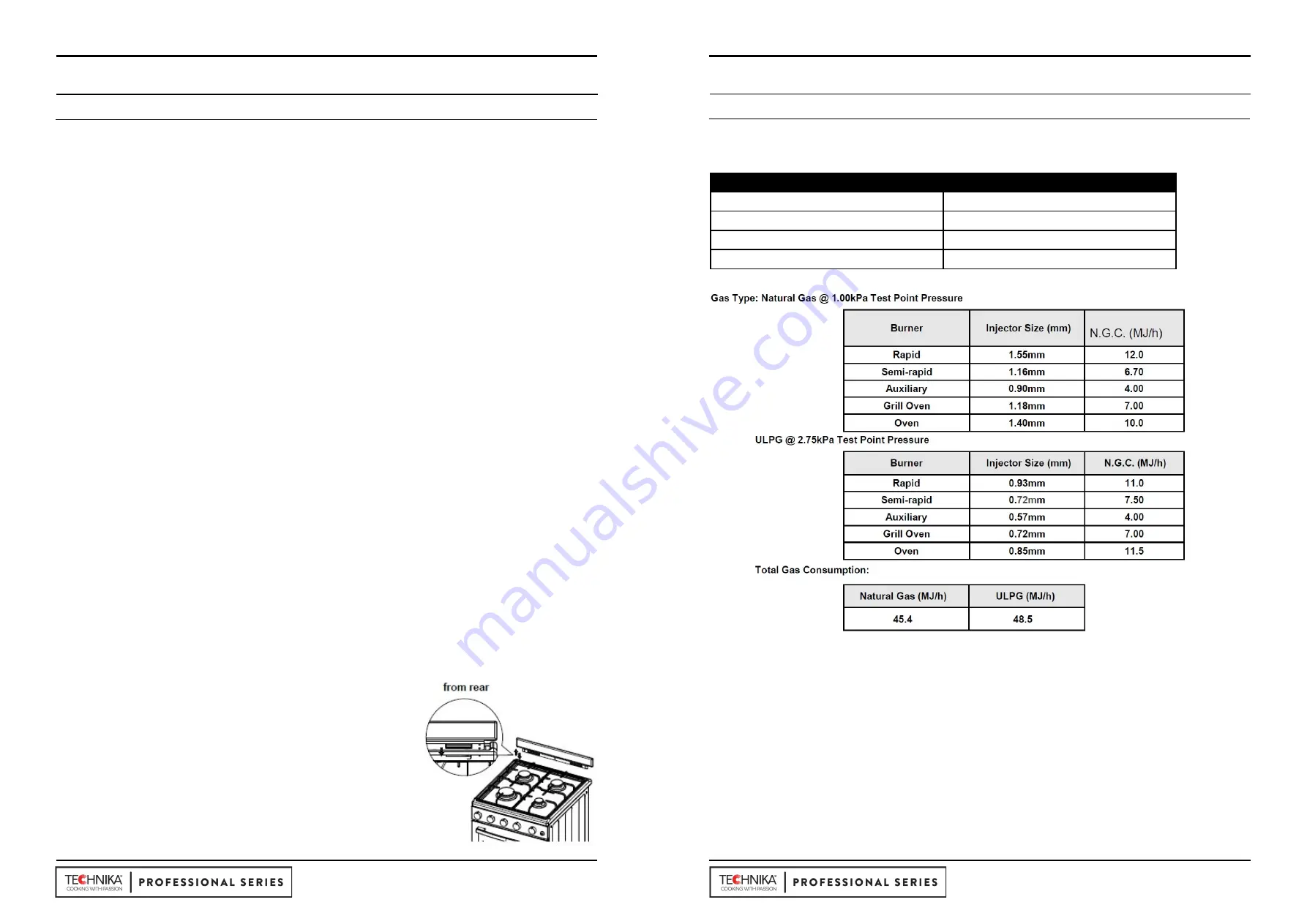

Model

TFS54FC-SGW

Oven capacity (L)

83

Burner power (MJ/h)

NG/LPG 36.36

Product dimension (mm)

540*600*910

Package size (mm)

590*712*960