PG 16

PG 17

SOLVING PROBLEMS

If you have a problem with your appliance, check the table below before calling service. You may be able to avoid

a service call by and avoid unnecessary inconvenience and expense.

For cooking problems, refer to Handling Baking Problems.

NOTE:

Only service centers should carry out servicing. Otherwise warranty may be void.

Problem

Causes

Remedy

Elements won’t work

Circuit breaker tripped

Check circuit breaker

Household fuse blown

Replace household fuse

Oven or grill not working

120 min Timer now in Manual position

Refer to 120 min timer instructions

Power not turned on

Switch on electricity

Control is incorrectly set

Reset controls

Circuit breaker tripped

Check circuit breaker

Oven light not working

Power not turned on

Switch on electricity

Household fuse blown

Check fuses

Circuit breaker tripped

Check circuit breaker

Lamp blown or loose in socket

Replace or tighten globe

Oven not hot enough

Heat escaping through incorrectly

sealed door

Check shelves or dishes are not

preventing door closing properly.

Check that door is fitted properly after

door removal for cleaning

Door seal is worn or has moved

Replace seal or re set it

Unit smoking when first used

Protective oils being removed

This is normal

Odour on first use of oven

Manufacturing oils on elements

This is normal

120minute timer buzzer not

audible

Timer not wound sufficiently

Allow 2-4 hours for odour to dissipate

(open all windows)

Oven shelf tight

Oven shelf not inserted corectly, may

be upside down or back to front

Turn timer knob past 15 minute mark.

Then turn to the required number of

minutes.

Clock display off

Household fuse blown or power

supply is off

Remove shelf and insert as per

diagram

Check fuses, power supply

INSTALLING THE GAS COOKER

Unpacking

Do not fit the burner crowns, burner caps and trivets until after the cooker has been installed.

Locating the cooker

This appliance must be installed by an authorised person in accordance with this instruction manual, AS/NZS 5601

– Gas installations (installation and pipe sizing), local gas fitting regulations, local electrical regulations, local water

regulations, local health regulations, Building Code of Australia and any other government authority.

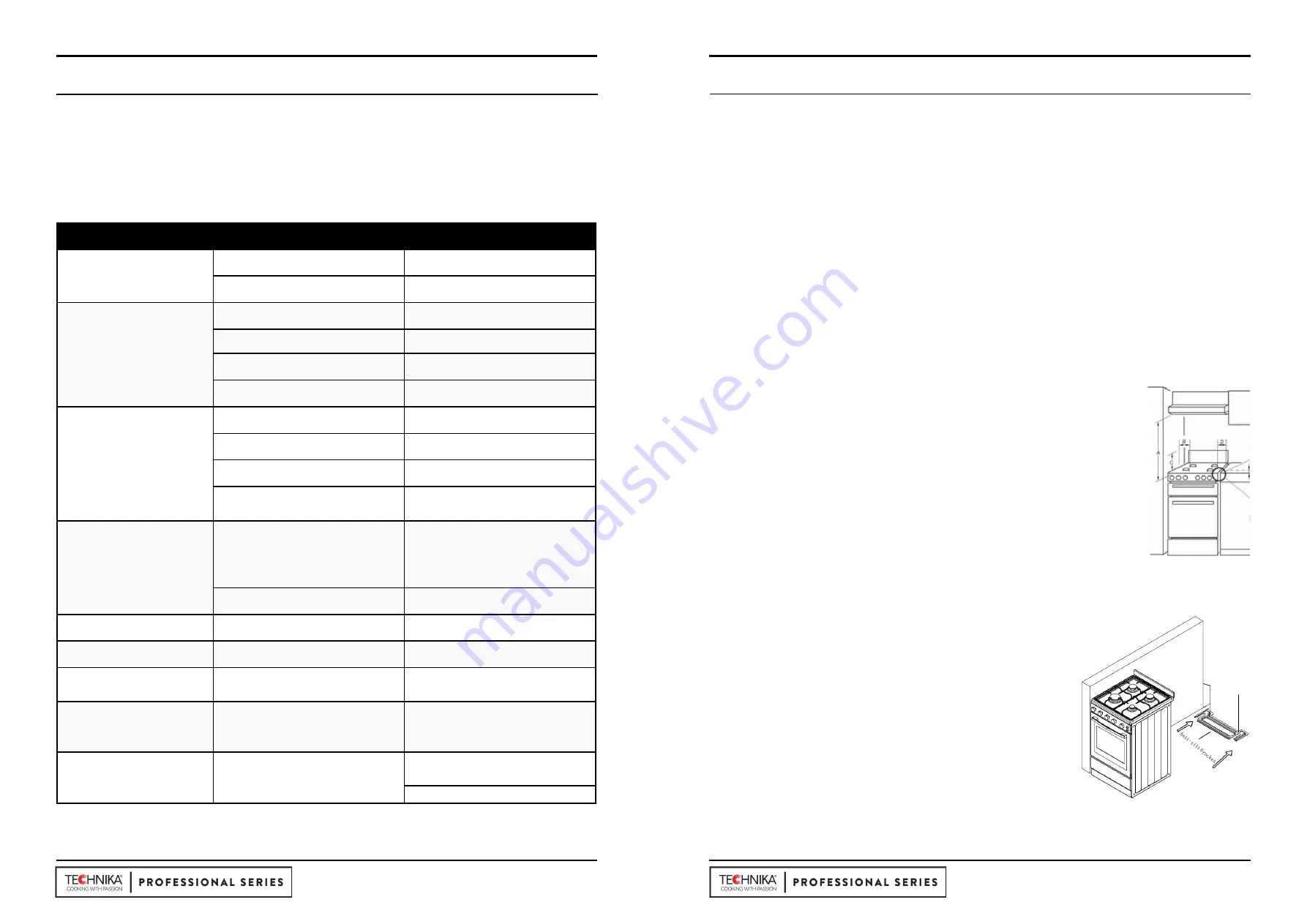

Overhead clearances—(Measurement A)

Range hoods and exhaust fans shall be installed in accordance with the manufacturer’s relevant instructions.

However, in no case shall the clearance between the highest part of the hob of the gas cooking appliance and a

range hood be less than 600 mm or, for an overhead exhaust fan, 750 mm

Side clearances—(Measurements B, & C)

Where B, measured from the periphery of the nearest burner to any vertical combustible

surface, or vertical combustible surface covered with toughened glass or sheet metal, is less

than 200 mm, the surface shall be protected to a height C of not less than 150 mm above

the hob for the full dimension (width or depth) of the cooking surface area. Where the gas

cooking appliance is fitted with a ‘splashback’, protection of the rear wall is not required.

Additional requirements for freestanding and elevated gas cooking appliances—

(Measurements D & E).

Where D, the distance from the periphery of the nearest burner to

a horizontal combustible surface is less than 200 mm, then E shall be 10 mm or more, or the

horizontal surface shall be above the trivet.

Overheat clearances -(Measurement A):

The distance between the highest part of the

hob of the gas cooking appliance should be higher than 600mm for a range hood and higher than 750mm for an

overheat exhaust fan.

Installation of the anti-tilt plate

Determine position of cooker and anti-tilt plate.

Securely fix the anti-tilt plate to the floor with appropriate fasteners. Fasten

the stability bolt bracket to the front grame with the 2 screws supplied.

Reposition the cooker back into the anti-tilt plate and then mark the position

of the stability bolt hole. Pull the cooker back out and drill the bolt location

hole. Use a 10mm masonry or wood drill. When drilling into concrete ensure

a minimum hole depth of 30mm. Reposition the cooker back into the anti-tilt

plate, aligning the stability bolt bracked with the 10mm drilled hole. Then slide

the bolt through the bracket and into the hole. Connect Electricity supply/gas

supply but do not turn on until installation is completed.