SAS UG 202205-01

9

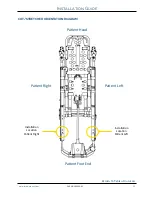

IDENTIFICATION OF COMPONENTS

LOCK PIN

The Lock Pin is made of stainless steel with a finger

ring. It is used to lock the Safety Arm System inside

the clamp block. It goes through the clamp block and

the bottom of the arm, locking the arm inside the

clamp block.

SAFETY PIN

The fixed safety pin is identified by the red round

handle mechanism used for locking the arm in the

upper position.

a) Side Lock Pin Aperture

b) Safety Pin with red handle

LOCK PIN WITH FINGER RING

a

b

CLAMP BLOCK WITH SAFETY PIN

Introduction