6

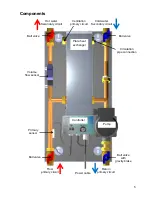

Installation

Preparation

A

safety valve

(max. 8 bar) must be installed in the cold water supply corresponding

to standards DIN 1988 und 4753, part 1 and TRD 721.

If the cold water pressure > 8 bar, fit a

diaphragm

pressure reducer

max. 8 bar.

The installation of

flushing equipment

before and after the plate heat exchanger in

the primary and secondary circuits is recommended for descaling or cleaning as nec-

essary.

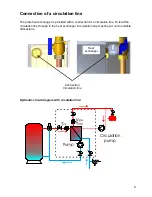

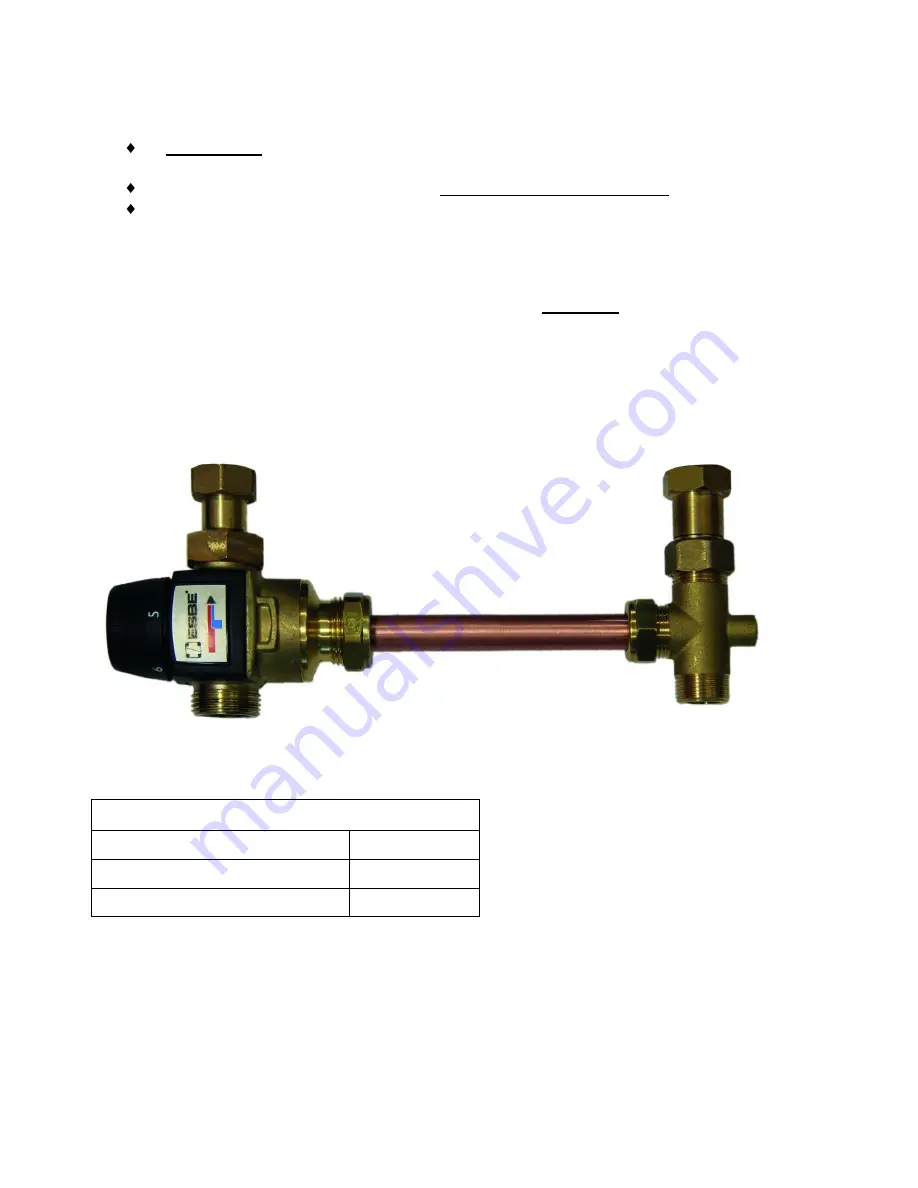

Special accessories: VMS pre-mixing set

If the tank is operated at a temperature higher than 70°C a

pre-mixer

that restricts the tem-

perature to less than 70°C must be used in the primary circuit.

The

VMS

pre-mixing set is suitable for both Fristar models (left pump, right pump).

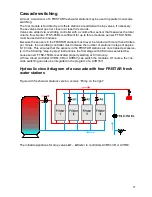

Figure

: Connection for Fristar with

right pump

Technical data

Setting range:

45°C

– 65°C

Flow coefficient of mixing valve

4.5m³/h

Connections for Fristar

¾”

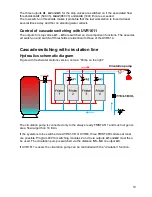

The thermal mixing valve is also available as an extra under the

TMV

designation.

Thread 3/4“

Thread 3/4“

Thread 3/4“

Thread 1

“