BIKE XT: Service & Maintenance manual - rev. 2.0

Page 6.5

6.2.

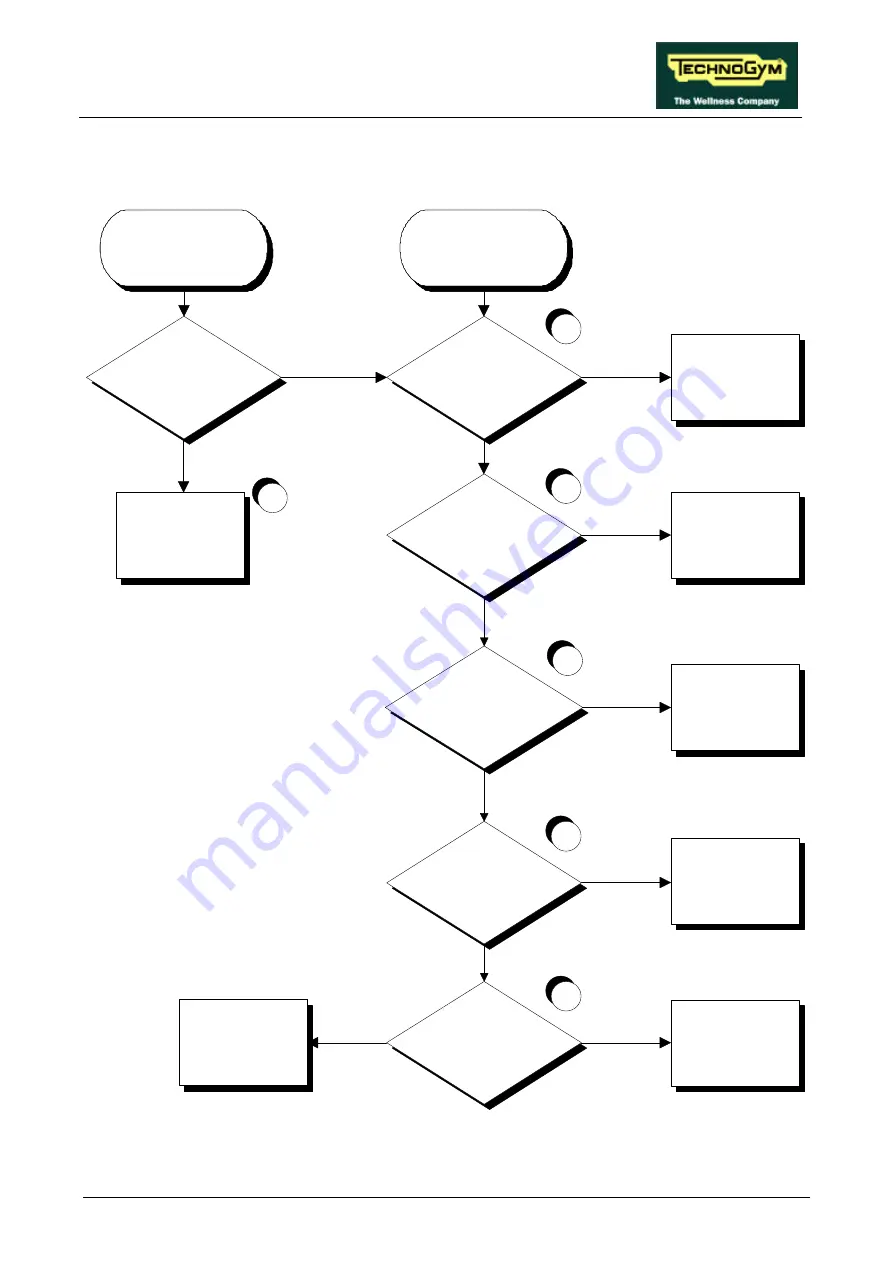

THE RESISTANCE IS NOT CORRECT

THERE IS NO

RESISTANCE

THE

RESISTANCE IS

NOT CORRECT

Are the Watt and RPM values

shown on the display correct?

Is the alternator excitation

voltage correct?

Is the excitation voltage at

the output of the alternator

interface board correct?

Is the power resistor value

correct?

Replace the power

resistor: see paragraph

7.8.

Check and/or replace

cable BX-5 connecting

the interface board to the

alternator

Replace the alternator:

see paragraph 7.9.

YES

NO

YES

NO

NO

YES

NO

YES

2

3

4

Does the CPU board send

the correct control signal to

the alternator interface

board?

Replace cable BX-1

connecting the CPU

board to the alternator

interface board

Replace the alternator

interface board: see

paragraph 7.8.

YES

YES

NO

NO

5

6

Replace the display CPU

board: see paragraph 7.3.

1

Is the control signal output by

the CPU board correct?

Check if the RPM signal

is correct

Summary of Contents for BIKE XT

Page 1: ...SERVICE MAINTENANCE MANUAL REV 2 0...

Page 2: ......

Page 4: ......

Page 16: ...BIKE XT Service Maintenance manual rev 2 0 Page 4 2 Page intentionally left blank...

Page 30: ...BIKE XT Service Maintenance manual rev 2 0 Page 6 12 Page intentionally left blank...

Page 46: ...BIKE XT Service Maintenance manual rev 2 0 Page 7 16 Page intentionally left blank...

Page 54: ...BIKE XT Service Maintenance manual rev 2 0 Page 8 8 Page intentionally left blank...

Page 58: ...BIKE XT Service Maintenance manual rev 2 0 Page 9 4 Page intentionally left blank...

Page 66: ...BIKE XT Service Maintenance manual rev 2 0 Page 11 6 Page intentionally left blank...

Page 67: ......