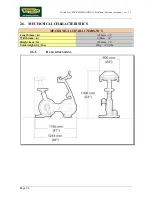

Summary of Contents for FORMA LINE BIKE FORMA DDC5 Series

Page 1: ...F FO OR RM MA A L LI IN NE E BIKE FORMA DDC5xxx Technical Assistance manual REV 1 1 ...

Page 2: ......

Page 4: ......

Page 8: ...Forma Line BIKE FORMA DDC5 Technical Assistance manual rev 1 1 Page iv Page blank ...

Page 28: ...Forma Line BIKE FORMA DDC5 Technical Assistance manual rev 1 1 Page 3 10 Page blank ...

Page 34: ...Forma Line BIKE FORMA DDC5 Technical Assistance manual rev 1 1 Page 5 4 Page blank ...

Page 58: ...Forma Line BIKE FORMA DDC5 Technical Assistance manual rev 1 1 Page 6 24 Page blank ...

Page 92: ...Forma Line BIKE FORMA DDC5 Technical Assistance manual rev 1 1 Page 7 34 Blank page ...

Page 116: ...Forma Line BIKE FORMA DDC5 Technical Assistance manual rev 1 1 Page 9 18 Page blank ...

Page 118: ......

Page 120: ......

Page 121: ......